UV DTF Gang Sheets: Boost Your Custom Printing Success

Share

Think of a professional sticker sheet, but supercharged. Instead of paper stickers, imagine creating incredibly durable, vibrant, full-color designs that you can apply to almost any hard surface. That’s the magic behind a UV DTF gang sheet. It’s a game-changing method that lets you print many different designs onto one large sheet, ready to be transferred as individual, high-quality decals.

What Exactly Are UV DTF Gang Sheets?

Simply put, a UV DTF gang sheet is a large, adhesive-backed film loaded up with your custom designs. The name "gang sheet" comes from the print industry term for "ganging" or grouping multiple jobs together on a single sheet. This is a brilliantly efficient way to work, as it cuts down on material waste and significantly lowers the cost of each individual design.

Instead of printing one sticker at a time, you can pack an entire sheet with different logos, graphics, or text. This makes it an absolute win for small businesses, Etsy sellers, and creators who need variety without a massive budget.

The "UV" part of the name stands for Ultraviolet. The designs are printed with a special ink that is instantly hardened—or "cured"—by UV light. This curing process creates a layered, tough decal that has the feel of a premium, flexible sticker. Best of all, it doesn't need any heat to apply, opening up a whole new world of items you can customize, especially things that can't handle a heat press.

The Multi-Layer Structure

The real genius here is how these transfers are constructed. Each design is a sandwich of several layers that work together to create a durable, easy-to-use product:

- Adhesive Layer: This is the base that sticks the design firmly to your chosen surface.

- Ink and Varnish Layers: Here's where the magic happens. These layers hold the vivid, UV-cured colors and a tough protective varnish that resists scratches and water.

- Carrier Film: A clear film holds the entire design together, letting you place it perfectly before you peel the film away, leaving only the graphic behind.

This clever multi-layer system is what makes it so versatile. You can apply these transfers to tricky surfaces like glass, metal, plastic, and even treated wood without any special equipment. It's no wonder the global DTF printing market is expected to jump from $2.72 billion in 2024 to $3.92 billion by 2030, according to research from Accio. People are catching on fast.

Key Takeaway: UV DTF gang sheets let you produce multiple, permanent, ready-to-apply decals in one go. It’s the perfect blend of bulk printing efficiency and total custom design freedom.

This method gives anyone a direct route to creating professional-looking custom products. To dive deeper into the process, check out our complete guide to UV DTF printing.

The Real-World Advantages of UV DTF Gang Sheets

So, what's all the fuss about with UV DTF gang sheets? It really comes down to three things that make a massive difference for creators and small businesses: serious cost savings, incredible versatility, and durability that lasts.

Think about it—instead of printing one design at a time, you're fitting multiple jobs onto a single sheet. This simple shift in thinking is a game-changer. You're squeezing every bit of value out of your materials, which means less waste and a much lower cost for each individual decal. Suddenly, those small, custom orders that used to be a headache are now perfectly profitable. If you're looking to tighten up your budget, we've got more tips on how to cut production costs in our guide.

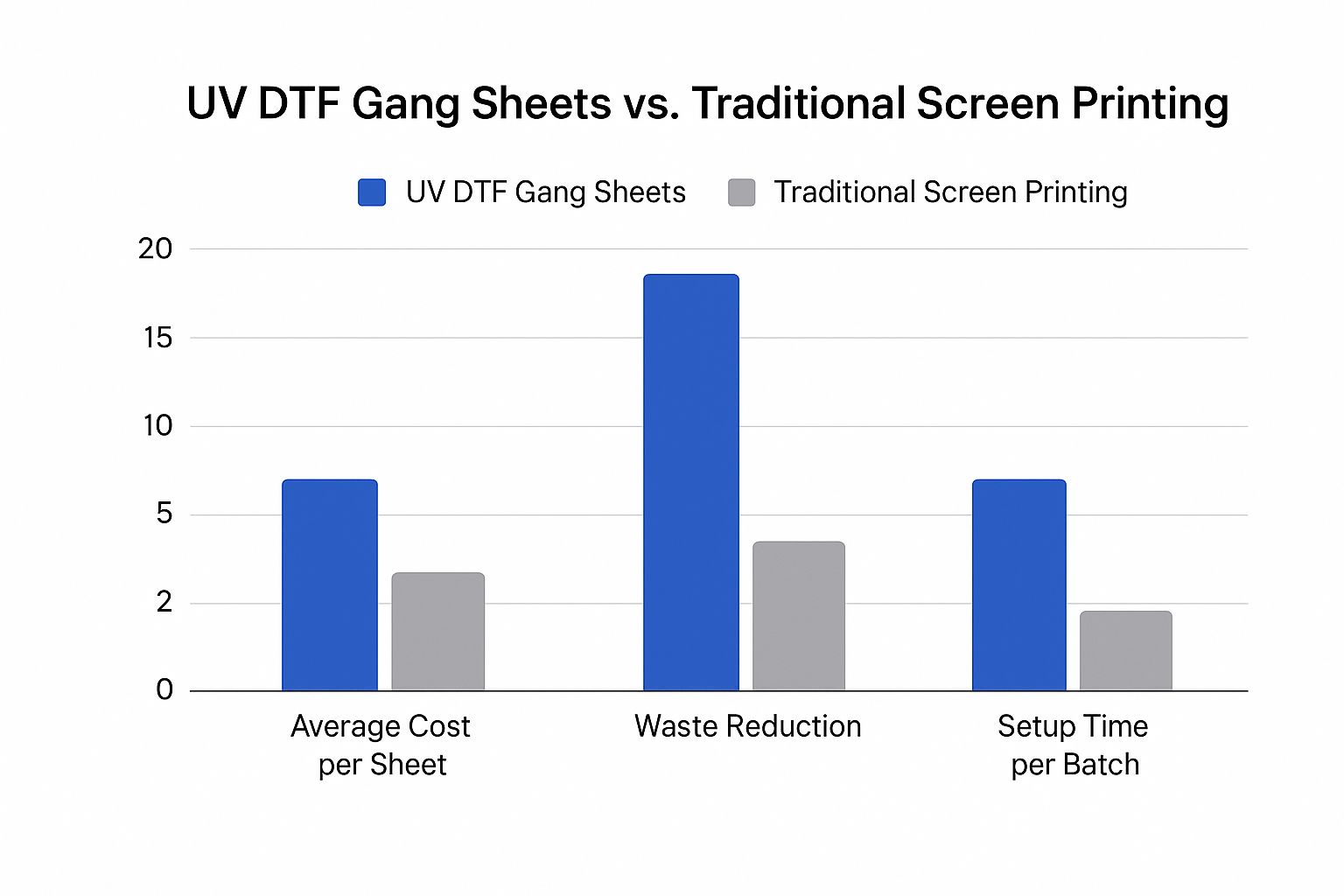

This infographic really puts the savings into perspective, especially when you stack it up against an old-school method like screen printing.

As you can see, the minimal setup and dramatically reduced waste give gang sheets a clear edge.

Decorate Almost Anything

For me, the most exciting part is the sheer freedom these transfers give you. You can decorate a massive range of hard surfaces without ever needing a heat press. This unlocks a whole new level of creative and commercial possibilities that used to be either too complicated or too expensive.

- Glass and Ceramics: Think custom mugs, pint glasses, and even decorative tiles with stunningly detailed, full-color art.

- Metals and Plastics: Easily brand things like stainless steel water bottles, plastic phone cases, or any kind of promotional gear.

- Wood and Acrylic: Perfect for making custom signs, unique awards, or one-of-a-kind home decor pieces.

Because the ink is cured instantly by UV light, the decal itself is incredibly tough. We're talking scratch-resistant, waterproof, and fade-proof. This isn't just a flimsy sticker; it's a permanent, professional-grade application built to withstand daily use and even the elements.

UV DTF Gang Sheets vs Traditional Methods

To see how these transfers stack up against other popular methods, let's break it down in a side-by-side comparison.

| Feature | UV DTF Gang Sheets | Adhesive Vinyl | Screen Printing |

|---|---|---|---|

| Material Compatibility | Excellent (glass, metal, wood, plastic, etc.) | Good (most smooth, non-porous surfaces) | Limited (depends on ink and surface prep) |

| Setup Time/Cost | Minimal; no screens or weeding | Low; requires weeding complex designs | High; requires screens for each color |

| Durability | High (scratch, water, and UV resistant) | Medium (can peel or fade over time) | Very High (but requires surface prep) |

| Color Capability | Full-color, gradients, and white ink | Limited to solid vinyl colors; layering is complex | Limited by the number of screens/colors |

| Best For | Small-to-medium runs of detailed, multi-color designs | Single-color logos, text, and simple shapes | High-volume, single-color jobs |

Ultimately, while each method has its place, UV DTF gang sheets offer a unique combination of flexibility, quality, and efficiency that's hard to beat for modern custom product businesses.

Unlock New Revenue with Hard Surface Printing

The real magic of UV DTF gang sheets happens when you start thinking beyond the obvious. Sure, customizing tumblers and phone cases is a fantastic place to start, but the technology really shines when you use it to decorate hard goods that were previously impossible to print on.

This is where you can break into entirely new markets. Imagine offering custom branding on sporting gear like helmets and skateboards, or creating high-end corporate gifts on glass awards. You could even personalize industrial parts with durable logos and serial numbers. Each one of these is a distinct and potentially lucrative business opportunity.

By offering high-quality, permanent designs on items that can’t handle heat or pressure, you can dramatically expand your product lineup. It positions your business as a go-to solution for a much wider range of clients.

Expanding Your Product Offerings

This flexibility means you can say "yes" to customer requests that your competitors have to turn down. You're no longer stuck with the usual promotional products. Just think about the possibilities:

- Corporate Branding: Put custom logos on electronics, premium office supplies, and crystal awards.

- Sporting Goods: Personalize helmets, water bottles, and equipment with team logos or player names.

- Bespoke Home Decor: Create one-of-a-kind designs on glass panels, ceramic tiles, and wooden signs.

- Event Merchandise: Produce limited-run branded items for concerts, festivals, and weddings.

The ability to decorate nearly any hard surface is a huge trend right now. In fact, demand is exploding—some reports show that over 40% of DTF inquiries are now for hard goods, not just the usual t-shirts and hoodies. You can dive deeper into these top DTF printing trends and what they mean for creators.

By mastering hard surface printing, you're not just adding a new product; you're building a more resilient and profitable business capable of serving diverse and specialized markets.

Getting Your UV DTF Transfer Application Just Right

Nailing that perfect, professional look with your UV DTF transfers really boils down to two things: prepping your designs the right way and applying the transfer with a bit of patience. If you get the design stage right from the start, you're setting yourself up for a final product that looks crisp, vibrant, and exactly how you pictured it.

First things first, you have to start with high-resolution artwork. 300 DPI (dots per inch) is the gold standard for a reason—it guarantees your prints will be sharp and clear. If you use a low-resolution file, you'll end up with a blurry, pixelated transfer that just doesn't look good. Just as important is making sure your artwork has a transparent background. This is what gives you that clean, die-cut appearance instead of a clunky white box around your graphic.

How to Set Up Your Gang Sheet for Success

Laying out your designs on uv dtf gang sheets is where you can really get the most bang for your buck. I like to think of it as a game of Tetris; you want to fit as many designs as possible onto the sheet, leaving almost no wasted space.

- Mix and Match Sizes: Tuck your smaller designs into the empty spaces created by the larger ones.

- Rotate Everything: Don't be afraid to turn your graphics sideways or upside down to find that perfect fit.

- Give Yourself Cutting Room: While you want to pack it in, leave just a tiny bit of space between each design so you can easily cut them apart without nicking the one next to it.

Spending a few extra minutes on your layout can significantly lower your cost per print, which is a huge win for any custom project. While we're talking about hard surfaces here, these design fundamentals also carry over to apparel. You can learn more about the specifics of heat transfer shirt printing if you're looking to branch out.

The Application Process: A Step-by-Step Guide

Once your designs are printed and cut from the sheet, applying them is pretty simple. Just follow these steps, and you'll sidestep the common pitfalls and get a solid bond every single time.

- Clean Your Surface: Give the item a good wipe-down with isopropyl alcohol. You need to get rid of any dust, fingerprints, or oils for the transfer to stick properly.

- Peel the Backing: Gently pull the white paper backing off the clear film. This will expose the sticky side of your design. Be careful here.

- Place and Press: Line up the transfer exactly where you want it. Once it’s in place, use a squeegee to press down firmly, working from the center out to push out any air bubbles.

- Remove the Carrier Film: Slowly peel the clear top film off. I find it works best to pull it back at a low, flat angle. If you see any part of the design lifting up, just lay the film back down, give that spot another good press, and then continue peeling.

Meeting Demand for Speed and Personalization

In today's market, customers want two things: they want it fast, and they want it theirs. This expectation for speed and personalization has turned UV DTF gang sheets from a neat printing trick into a must-have tool for any serious print business. They're a direct answer to the "I need it now" culture.

This technology is a game-changer for handling small-batch orders profitably. Think about the bread and butter of modern commerce: Etsy shops, influencer merch lines, and limited-edition product drops. Instead of dealing with expensive, time-consuming setups for every single design, you can run dozens of completely different graphics all at once, on a single sheet.

This approach absolutely slashes production time. You can take a customer's concept and have a finished product ready to ship in a fraction of the time of older methods. That kind of speed gives you the confidence to promise—and deliver on—rapid fulfillment for custom orders, which is a massive competitive edge.

Staying Agile with On-Demand Printing

The on-demand model isn't just a trend; it's how successful businesses operate now. It's no surprise that research points to personalization and quick turnarounds as the main drivers behind the rise of UV DTF printing. In fact, a reported 65% of independent creators are now building their businesses around next-day or 48-hour production cycles for their custom goods.

That impressive speed is only possible because of how gang sheets work. Being able to print, cut, and apply a whole mix of unique designs from one sheet is why many shops have seen a 35% increase in orders for personalized items since 2020. You can dig deeper into these business-boosting gang sheet insights to see the full picture.

By integrating UV DTF gang sheets, your business can meet modern consumer demands head-on. You gain the ability to produce highly customized products at scale and with the speed necessary to thrive.

At the end of the day, this isn't just about a new way to print. It’s about creating a smarter, more responsive business model that’s perfectly in sync with what modern customers actually want.

Got Questions? Let's Talk UV DTF Gang Sheets

Even when you've got the basics down, it's natural to have a few practical questions pop up before you dive into your first UV DTF project. Let's tackle some of the most common ones so you can get started with confidence.

Just How Permanent and Waterproof Are These Transfers?

You bet they are. When you apply a UV DTF transfer correctly to a clean, non-porous surface, it’s there for the long haul. The UV curing process creates a seriously tough, durable layer that’s not just water-resistant but also holds up great against everyday bumps and scratches.

This is exactly why they're perfect for items that get a lot of handling—think custom mugs, phone cases, keychains, or even outdoor signs. They’re built to last. For things like drinkware that will be washed, a gentle hand-wash is always the best way to keep the design looking pristine for as long as possible.

Can I Put UV DTF Transfers on a T-Shirt?

This is a big one, and the answer is a hard no. UV DTF transfers are strictly for hard, smooth surfaces. The adhesive is specifically designed to grab onto materials like glass, metal, plastic, and sealed wood—not fabric.

If you try to put one on a t-shirt or any kind of textile, it just won’t work. It’ll peel right off or disappear in the first wash. For decorating apparel, you need to stick with traditional heat-press DTF transfers, which are made to bond with fabric fibers.

The rule of thumb is simple: UV DTF is for hard goods. Regular DTF is for textiles. Getting them mixed up is a fast track to frustration and wasted supplies.

Do I Need a Heat Press to Apply These?

Here’s one of the best parts about working with UV DTF: no special equipment is needed for application! You can put that heat press away. There’s no heat, no special oven, and no complicated machinery involved.

All it takes for a flawless, professional-looking application is a clean surface and something to apply firm, even pressure with. A squeegee is perfect, but a credit card or any stiff, flat-edged tool will do the job just as well. This simplicity makes it a fantastic option for everyone, from hobbyists working at their kitchen table to full-scale print shops.

Ready to create stunning, durable designs on almost any hard surface? At Cobra DTF, we provide top-quality, American-made UV DTF gang sheets that deliver vibrant colors and lasting performance. Get started today by exploring our custom UV DTF transfers.