How to Reduce Production Costs in Your Custom Apparel and Drinkware Shop

Share

If you're in the custom shirts, tumblers, and cups game, you know that your real challenge isn't just making cool stuff—it's keeping production costs from eating your profits alive. The key is to spot and slash those hidden expenses. For many shops, this means finally moving on from old-school, time-sucking methods like vinyl cutting and embracing something far more efficient, like DTF and UV DTF transfers.

Switching to a specialized supplier like Cobra DTF lets you tap into the highest quality transfers without dropping a fortune on new equipment, helping you reduce your costs while boosting your quality.

Why Hidden Costs Are Hurting Your Custom Print Shop

When you're juggling orders for custom shirts, tumblers, and cups, it's easy to get tunnel vision. You're watching the cost of blank apparel and shipping boxes like a hawk. But the real profit killers? They're the hidden costs, the ones lurking just below the surface that quietly drain your bank account and stunt your growth.

Just think about the hours your team spends weeding those crazy-detailed vinyl designs for a single t-shirt. That’s not just time—it’s a direct labor cost that balloons with every complex order. Every minute someone spends picking tiny pieces of vinyl from a backing sheet is a minute you're paying for, and it’s a cost that rarely makes it into the final price tag.

The True Cost of Inefficiency

Inefficiency is more than just a bottleneck; it’s a cash drain. For shops cranking out custom shirts, tumblers, and cups, it usually shows up in a few familiar, painful ways:

- Production Gridlock: You know the drill. A single four-color vinyl shirt needs multiple cuts, a ton of weeding, and several presses. This creates a traffic jam in your workflow, slowing down the entire line and capping the number of orders you can push out the door each day.

- Material Graveyard: We've all been there. Misaligned layers on a shirt, a botched application on a tricky curved tumbler, or vinyl that rips mid-weed. These aren't just frustrating moments; they're wasted materials and money straight into the trash can.

- Lost Opportunities: How often have you had to say "no" to a potentially huge order because the multi-color, detailed design was just too much of a headache to be profitable with vinyl? Every time you turn down a job, you're not just losing a sale—you might be losing a long-term customer to a competitor who can handle it.

These small leaks add up, and over time, they can seriously damage your business. A workflow built on tedious, multi-step processes is expensive by nature and a nightmare to scale. This is exactly where modern solutions like DTF Transfers for apparel and UV DTF Transfers for hard goods like tumblers change the game.

By shifting to a simpler, more streamlined process, you can directly attack these hidden costs. For instance, a single DTF transfer replaces four separate vinyl layers. That move alone instantly wipes out all the time spent weeding and layering, which can slash labor costs on complex jobs by over 75%.

At the end of the day, cutting production costs starts with an honest look at where your time and money are really going. Once you identify these profit killers, you can make smart changes—like bringing in DTF technology—that don't just save you money but open up new ways to grow your custom shirt and tumbler business.

Slash Your Apparel Production Time with DTF Transfers

In any custom shirt shop, time is money. Labor often eats up the biggest chunk of your production budget, and that's exactly where Direct-to-Film (DTF) technology can be a game-changer for your bottom line. It directly attacks the most time-consuming parts of old-school methods like heat transfer vinyl (HTV), making them practically obsolete for custom apparel.

Let's paint a picture. A customer comes in wanting a small batch of custom shirts with a complex, four-color logo. If you're using HTV, you know the drill: cut four different vinyl sheets, painstakingly weed each one, and then try to line them up perfectly for multiple presses. It’s slow, tedious work where one tiny mistake can ruin the whole shirt.

DTF takes that entire multi-step headache and boils it down to one simple move: press and peel. A high-quality DTF transfer delivers vibrant, durable results in a fraction of the time.

This isn't just a minor tweak to your workflow; it's a complete overhaul. By getting rid of weeding and layering, you can knock out orders in a tiny fraction of the time. This frees you and your team up to take on more jobs, boosting your shop's capacity without having to bring on more people.

The Real-World Cost Comparison

Let’s look at a practical example to see how the savings really stack up. Take that one custom shirt with the four-color design. The difference in time and materials between HTV and DTF is stark.

With HTV, the labor for weeding and multi-layering a detailed design can easily eat up 15-20 minutes per shirt. Add in the material cost of four separate vinyl colors, and your total cost gets surprisingly high, especially for a one-off or small run.

Now, compare that to a DTF transfer from a provider like Cobra DTF.

The entire application for a full-color DTF transfer takes less than a minute. You position it, press it for about 15 seconds, and you're done. The labor savings are instant and huge—we're talking about cutting production time on a single shirt by over 90%.

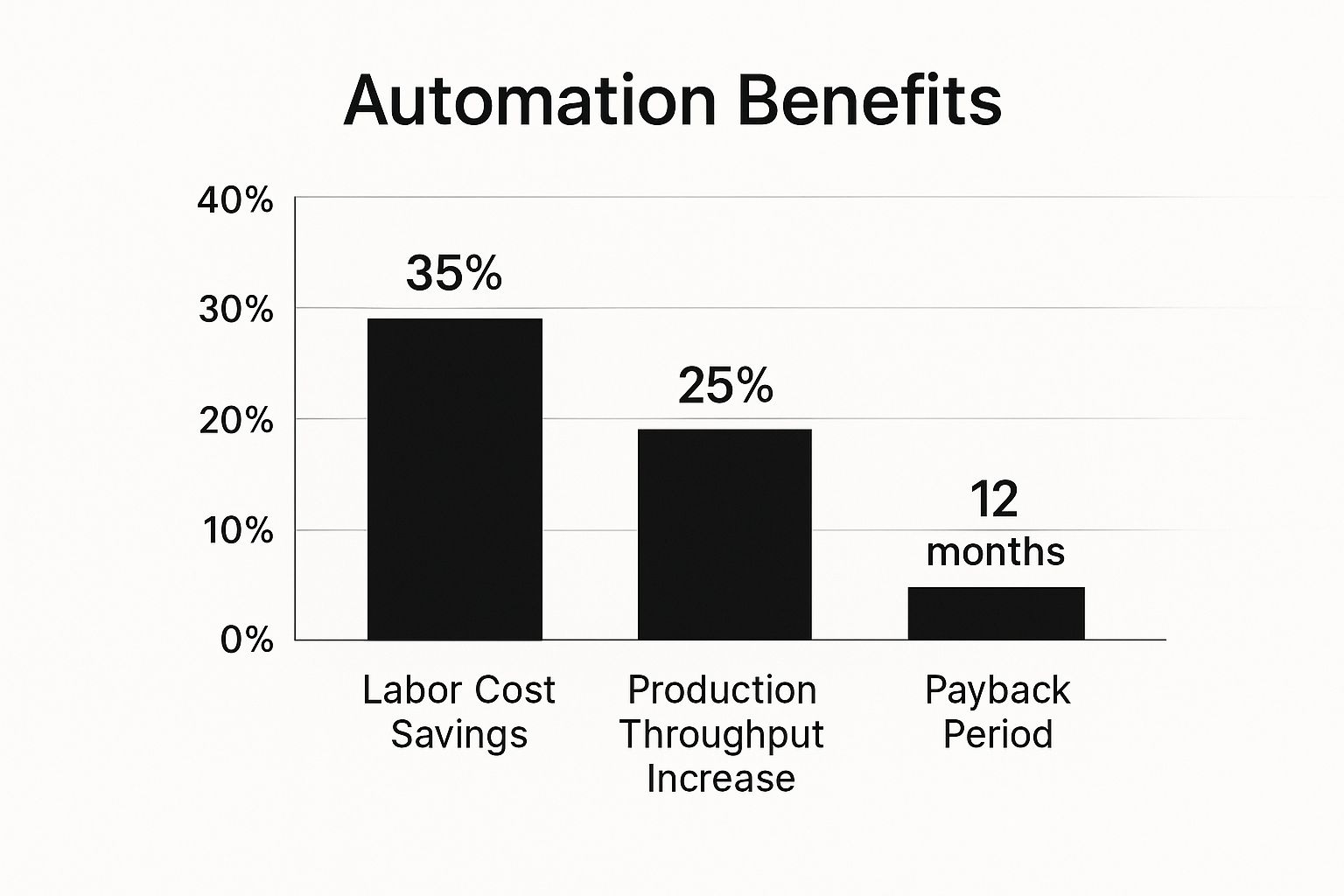

The image below gives you a sense of how adopting efficient tech like this directly impacts your business.

As you can see, the benefits go way beyond just speed. It leads to major labor cost reductions and a fast return on your investment. This is the kind of smart move that helps small businesses punch above their weight.

Cost Comparison Traditional Vinyl vs DTF Transfers

To really bring this home, let’s put some estimated numbers side-by-side. The table below breaks down the costs and time involved for producing a single, multi-color custom shirt using both methods.

| Cost Factor | Traditional HTV (4-Color Design) | DTF Transfer (4-Color Design) |

|---|---|---|

| Material Cost | $2.50 - $4.00 (for four colors of vinyl) | $1.50 - $3.50 (for one pre-printed transfer) |

| Labor Time (Est.) | 15-20 minutes | ~1 minute |

| Labor Cost (at $20/hr) | $5.00 - $6.67 | ~$0.33 |

| Total Estimated Cost | $7.50 - $10.67 | $1.83 - $3.83 |

Note: Costs are estimates and can vary based on suppliers, design complexity, and local labor rates.

The numbers don't lie. Even with conservative estimates, the savings are significant. Shifting to DTF not only cuts your direct costs but also dramatically increases your potential output and profit margins on every single shirt you sell.

A Smarter Way to Scale Your Business

Jumping into new technology doesn't have to mean draining your bank account. In fact, modern manufacturing is all about smart cost management. With material prices on the rise, businesses are focusing on efficiency through technology and automation, not just cutting corners.

This is where partnering with a specialized DTF supplier like Cobra DTF becomes a brilliant strategy. By outsourcing your transfer production, you sidestep the need to buy and maintain your own expensive DTF printers, curing ovens, and ventilation systems, while ensuring you receive the highest quality transfers.

This "pay-as-you-go" approach is a win-win for small shops:

- No Huge Upfront Cost: You avoid a five-figure investment in equipment and training. Your costs scale directly with your sales.

- Predictable Per-Item Cost: Budgeting becomes a breeze. You know the exact cost of every transfer, which lets you price your products with confidence and protect your profit margins.

- Guaranteed Quality: Reputable suppliers like Cobra DTF have their process dialed in. You get vibrant, durable, and perfectly registered transfers every time, which means no more wasted materials from print errors.

For businesses specializing in custom shirts, tumblers, and cups, this is a low-risk, high-reward way to grow. You get all the speed and quality of DTF while keeping your operation lean and flexible. To learn more about the tech behind it, check out our complete guide on DTF custom transfers. It’s a great deep dive into what makes them so effective.

Expand Into Hard Goods with UV DTF Transfers

Slashing your apparel production time is a huge win, but what if you could tap into a whole new, high-margin revenue stream without buying a bunch of new equipment? That's the opportunity waiting for you in custom tumblers, cups, and other hard goods.

For shops that live and breathe custom shirts, the world of tumblers, cups, and mugs can feel like a different planet. It usually means investing in expensive sublimation printers, dedicated heat presses, and all sorts of mug wrappers.

But there’s a much simpler way to get in the game.

This is where UV DTF Transfers change everything. They're made specifically for hard, non-porous surfaces like tumblers and cups and, get this—they don't require any heat at all. This tech lets you offer durable, vibrant, full-color designs on items that used to be a real headache to customize.

The Beauty of the 'Apply and Peel' Method

Let's be honest, the biggest hurdle to selling custom drinkware has always been the gear. Sublimation alone requires a special printer, pricey inks, polyester-coated blanks, and a collection of heat presses or convection ovens. It's a lot to take on, and it’s a big reason why figuring out how to reduce production costs is a constant battle for growing shops.

UV DTF transfers let you sidestep all of that. The application is almost laughably simple:

- Wipe the Surface: Give the tumbler, cup, or mug a quick clean to get rid of any dust or oils.

- Place the Transfer: Position the adhesive transfer right where you want it. Take a second to make sure it's straight.

- Squeegee It Down: Use a squeegee and press firmly over the entire design. You want to make sure the adhesive gets a good grip on the surface.

- Peel It Off: Slowly pull back the clear carrier film. What's left behind is a crisp, permanent design.

And that’s it. No heat. No special jigs. No complicated machinery. This dead-simple process means fewer mistakes, less wasted product, and way lower labor costs for each item you sell.

For a small shop, this is a game-changer. You can go from customizing a t-shirt to a premium tumbler in a matter of minutes, using nothing more than the transfer and a squeegee. It practically eliminates the barrier to entry for the hard goods market.

Durability and Quality That Actually Sells

I get it—a common worry when branching into hard goods is durability. Nobody wants an angry email about a design peeling off a custom tumbler after one wash.

The good news is that high-quality UV DTF transfers are built to last. They create a permanent, waterproof, and scratch-resistant bond that can handle daily use. The ink is cured with ultraviolet light during printing, which results in a tough, slightly raised finish that feels a lot like high-quality screen printing. This lets you confidently sell custom drinkware that not only looks professional but is made to last, which means happier customers and better reviews for your shop.

Opening Up New High-Margin Revenue Streams

Adding custom tumblers and cups to your lineup is more than just diversification; it's a direct path to better profit margins. Custom drinkware consistently fetches a higher price than a t-shirt, but with UV DTF, your actual cost to produce it stays incredibly low.

Think about the possibilities this opens up:

- Corporate Gigs: Businesses are always on the hunt for branded swag like mugs and water bottles.

- Personalized Gifts: Custom tumblers are a hot item for weddings, birthdays, and holidays.

- Local Teams and Events: Offer custom cups for sports teams, school clubs, and community fundraisers.

By working with a supplier like Cobra DTF, you can order top-notch transfers on-demand. Check out their collection of UV DTF Transfers to see the possibilities. This lets you test the waters without sinking a ton of cash into inventory.

This pay-as-you-go approach keeps your overhead low while you explore this profitable new niche. You can take on small, one-off orders just as easily as large batches, making your business more flexible and quick to respond to whatever your customers are asking for.

How Outsourcing to Cobra DTF Slashes Your Overhead

When you're wrestling with how to cut production costs, one of the biggest forks in the road is deciding between producing in-house or outsourcing. For small shops making custom shirts, tumblers, and cups, this choice can make or break your profitability. The DIY route looks appealing at first glance, but it often comes with a mountain of hidden expenses that can easily sink a growing business.

Working with a specialist like Cobra DTF is more than just a convenience—it's a strategic shift in your entire cost structure. You move away from risky, unpredictable capital investments and lock in a simple, manageable cost for each item you produce. Cobra DTF helps you reduce costs while providing the highest quality transfers, simplifying your whole operation from day one.

Skip the Massive Upfront Equipment Costs

The most immediate win from outsourcing is dodging the huge price tag on professional equipment. A solid DTF printing setup isn't just one printer; it's a whole ecosystem of expensive machinery that adds up fast.

If you bring production in-house, you're on the hook for:

- High-End DTF Printers: A reliable, commercial-grade model will easily set you back tens of thousands of dollars.

- Curing Ovens and Shakers: These are non-negotiable for properly prepping transfers, and they'll add thousands more to your startup bill.

- Proper Ventilation Systems: DTF printing creates fumes, so a professional—and often costly—ventilation system is a must for keeping your workspace safe.

When you outsource to Cobra DTF, those expenses vanish. Your capital stays in your pocket, free to be used for things that actually grow your business, like marketing or stocking up on more blank inventory, instead of being sunk into depreciating machinery.

Sidestep the Hidden Headaches of DIY Production

Beyond the big-ticket items, it's the day-to-day costs of running your own DTF setup that really eat into your profits. These "hidden" costs are relentless and notoriously hard to budget for, turning in-house production into a financial minefield if you're not prepared.

Outsourcing isn't just about avoiding a big purchase. It's about getting rid of a long list of ongoing operational headaches. You're trading a bunch of unpredictable expenses for one clear, fixed cost that scales perfectly with your sales.

Here’s a quick look at what you’re really paying for when you go the DIY route:

- Wasted Materials: There's a steep learning curve to dialing in a DTF printer. You're going to burn through expensive ink and film on misprints, color matching problems, and alignment errors. It’s part of the process.

- Maintenance and Downtime: These machines need constant attention. When one breaks down, you’re not just paying for a technician; you're losing money every single minute you can't get an order out the door.

- Skilled Labor: Running and maintaining DTF equipment isn't a job for a rookie. You either have to spend countless hours becoming an expert yourself or hire a skilled operator, which adds a hefty salary to your monthly overhead.

By partnering with Cobra DTF, you hand off all that risk. Our team has the expertise to deliver perfect, press-ready transfers every single time, ensuring the highest quality. This cuts waste to zero and ensures your final products—from custom shirts to tumblers decorated with UV DTF—look absolutely flawless.

The homepage for Cobra DTF shows our commitment to quality and quick turnarounds, which we know are critical for any print shop.

This focus on providing high-quality, USA-made products with guaranteed fast shipping lets you run your business with more agility and confidence.

Simplify Your Budget and Scale with Zero Friction

At the end of the day, outsourcing just makes your financial life easier. Instead of juggling a messy mix of equipment payments, maintenance bills, and material waste, you have one simple, predictable number: the cost per transfer. This makes quoting jobs and managing your cash flow incredibly straightforward. It's a game-changing strategy for any business trying to figure out how to reduce production costs while actually improving quality.

This model is also built for scale. Whether you get an order for one custom shirt or one thousand, your cost per item stays the same. You never have to sweat about an expensive printer sitting idle during a slow week or, worse, not being able to keep up when you get a massive order. You just order what you need, when you need it. That kind of flexibility is a massive competitive advantage.

For more ideas on how this compares to other business models, check out our guide on finding the right print on demand suppliers to fit your specific needs.

Make Your Workflow a Profit-Generating Machine

Having top-notch tools like DTF and UV DTF transfers is a great start, but your day-to-day process is where you really make your money. An efficient workflow is what turns that cool technology into a lean, mean, profit-making machine. It all comes down to looking at every single step—from the moment an order for a custom shirt or tumbler lands to the second it's out the door—and asking, "How can I do this faster, smarter, and cheaper?"

This isn't about cutting corners or rushing through jobs. It's about getting rid of wasted motion, redundant tasks, and the little things that eat up your time. You’d be surprised how a few simple tweaks to your shop's layout and process can slash labor costs, which is often a custom apparel and drinkware shop's biggest single expense.

Master the Art of Batching

One of the quickest wins for efficiency is to stop treating every order like a one-off project. Start thinking more like an assembly line and batch similar tasks together. It makes a world of difference.

- Group by Garment or Color: Got five orders for black tees and three for white hoodies? Press all the black tees at once, then all the white hoodies. This simple switch means you're not constantly swapping out blanks or fiddling with your heat press settings.

- Pre-Press in Bulk: Set aside some time to pre-press a whole stack of shirts. Getting all the moisture and wrinkles out at once is so much faster than doing it one by one as orders come in.

- Prep Your Materials: Before you even approach the heat press, get your DTF transfers trimmed and organized. If you're doing UV DTF, have your tumblers and cups wiped down and lined up, ready to go. A few minutes of prep work saves you a ton of running back and forth later.

This "batching" mindset creates a natural rhythm in your shop, letting you flow through orders with some real speed and precision.

Squeeze Every Penny from Your Gang Sheets

When you're trying to figure out how to reduce production costs, the cost of each individual design is a huge piece of the puzzle. This is where using gang sheets from a supplier like Cobra DTF becomes your secret weapon. A gang sheet is just a large sheet of transfer film where you can cram multiple designs.

The more designs you can strategically fit onto a single sheet, the lower your cost per transfer plummets. This is one of the most direct and impactful ways to boost your profit margin on every single item you sell.

Don't just randomly place designs on the sheet. Be smart about it. Fill in those awkward empty spaces with smaller, popular graphics you can sell as add-ons—think pocket logos, sleeve hits, or even little decals for hats. This turns what would have been wasted material into pure, easy profit.

Embrace a "Just-in-Time" Inventory Strategy

Sitting on massive piles of blank shirts and tumblers is like letting cash collect dust in a corner. It ties up your money and eats up precious space. The beauty of DTF and UV DTF is their speed, which makes a "just-in-time" inventory model a totally practical approach for small shops.

Since you can press a shirt or wrap a tumbler in a minute or less, you don't need a huge stockpile of finished products. You can order your blank goods as you need them, knowing you can fulfill orders almost as soon as the delivery truck pulls away. This keeps your cash flow healthy and saves you from getting stuck with a mountain of unpopular sizes or colors.

This lean thinking is exactly what bigger industries are doing to stay competitive. In fact, one of the main ways large-scale manufacturers cut costs is by adopting smart technology. By 2025, an estimated 70% of manufacturers will be using IoT devices for real-time monitoring, and the predictive maintenance that comes with it can cut unplanned downtime by 50%. It all proves the same point: smarter processes lead directly to a healthier bottom line. You can read more about these manufacturing efficiency trends and how they apply across the board.

Your Game Plan for Slashing Production Costs

Let's put all this into practice. The road to lower production costs isn't about compromising on the quality of your work. It's about being smarter and shedding the old-school, time-sucking methods that are quietly eating away at your profits on every custom shirt, tumbler, and cup you produce.

Your action plan is really pretty simple, and it leans on technology that's already proven to work.

T-Shirts and Apparel: Make the Switch to DTF

For anything fabric-based, like your custom t-shirts, hoodies, and totes, DTF Transfers are going to be a game-changer. Think about it: you can completely eliminate the painstaking process of weeding and layering vinyl. That multi-step nightmare becomes a single, quick press.

This move alone dramatically cuts your labor costs. It also frees you or your team to pump out more orders, which means your shop’s capacity—and its bottom line—gets a serious boost.

Tapping into New Markets with UV DTF

Once you've got your apparel dialed in, it's time to look at hard goods. This is where the real high-margin opportunities are. UV DTF Transfers are your ticket into this space, letting you customize things like tumblers and cups without needing any heat presses or bulky sublimation equipment.

The application is literally peel-and-stick. This means less material waste from misprints, fewer frustrating errors, and a whole new income stream that costs you almost nothing to get started with.

The smartest way to jump in is to partner with a dedicated supplier like Cobra DTF. This gives you a low-risk, high-reward entry point. You don't have to sink thousands into equipment or go through a painful learning curve. You just get top-tier, highest-quality transfers whenever you need them.

At the end of the day, adopting these technologies is a direct investment in your shop’s future. By bringing DTF and UV DTF into your workflow, you’re not just cutting costs; you're building a more efficient, scalable, and ultimately more profitable business. You'll be able to confidently take on those complex, multi-color jobs you used to turn down and truly compete in the custom products game.

Got Questions? We’ve Got Answers.

Making a big change in your production process always brings up a few questions. It’s a smart move to do your homework. Here are some of the most common things we get asked by shop owners looking to bring down their costs with DTF and UV DTF transfers.

Is There a Minimum Order Quantity with Cobra DTF?

Nope. And that’s a game-changer for small businesses.

You can order just one single transfer or a small gang sheet if you're testing out a new design or fulfilling a one-off custom request. This flexibility is huge—it means you aren’t sinking your cash into inventory that might just sit on a shelf. Keeping that overhead low is everything.

Essentially, you pay for what you need, when you need it. Whether you're making one custom hoodie or a hundred, your costs scale right along with your orders, keeping things predictable and easy to manage.

How Well Do UV DTF Transfers Hold Up on Tumblers?

They are seriously tough. When you apply a high-quality UV DTF transfer correctly to a hard, smooth surface like a tumbler or cup, you get a permanent, waterproof, and scratch-resistant design.

The secret is the UV-curing process, which creates a slightly raised, high-gloss decal that’s built to last. They can handle daily use and hand washing without a problem.

This isn't just about looking good—it's about quality. You're giving your customers a premium product that lasts, which builds your reputation and cuts down on the headaches and costs of having to do remakes or handle returns. Cobra DTF provides the highest quality to ensure customer satisfaction.

What’s the Learning Curve Like for Applying These Transfers?

You’ll be up and running in no time. Honestly, this is one of the best parts for busy shops.

- DTF for Apparel: If you know how to use a heat press, you're already 90% of the way there. It’s as simple as lining up the transfer and pressing it for about 15 seconds.

- UV DTF for Hard Goods: This is even easier. Think of it as a high-tech sticker. It's a simple peel-and-apply method that doesn't require any heat or special tools—just a clean surface and a good squeegee.

Because it's so straightforward, you can slot these transfers into your workflow almost immediately. You'll start seeing how they reduce your production costs right away, without losing valuable time to a long training process.

Ready to see for yourself how simple and effective these transfers can be? Cobra DTF provides top-quality, USA-made DTF and UV DTF transfers designed to help you slash costs and grow your product offerings.