A Guide to DTF Custom Transfers

Share

So, what exactly are DTF custom transfers? In simple terms, they're high-quality, full-color designs printed onto a special clear film. These prints are ready to be heat-pressed onto almost any fabric you can think of.

Think of them as a seriously upgraded version of the old iron-ons. They're incredibly soft to the touch, built to last, and can reproduce designs with stunning, photorealistic detail.

Your Guide to Modern Apparel Customization

If you’ve been looking for a way to create professional-grade custom apparel without a massive investment or a complicated learning process, DTF custom transfers are your answer. This technology neatly fills the gap left by older printing methods, giving you the best of all worlds. You get the vibrant, unlimited colors of Direct to Garment (DTG) printing combined with the amazing material versatility of screen printing.

Just imagine being able to use one type of transfer for a whole range of different items. That’s the magic of DTF.

Why Are DTF Transfers Gaining Popularity?

The demand for personalized, on-demand apparel has absolutely exploded, and DTF technology showed up at the perfect time to meet that need. The numbers tell the same story. The global Direct to Film printing market was valued at USD 2.72 billion in 2024 and is expected to climb to USD 3.92 billion by 2030. This growth is all thanks to creators and businesses who need a reliable, high-quality way to customize products.

This method breaks down the old barriers to entry, making it a perfect fit for:

- Small Businesses: Now they can create branded merch without being forced to buy and store huge quantities of inventory.

- Independent Artists: It's an ideal way to sell intricate, full-color art on t-shirts, hoodies, or tote bags.

- Custom Apparel Shops: They can now take on small, diverse orders and turn them around quickly while still making a profit.

The DTF Advantage Explained

Let's compare it to the old-school methods. Screen printing, for instance, requires a separate screen for every single color in a design. That gets expensive and complicated fast. DTF, on the other hand, prints the entire full-color design in one go. No color limits, no extra fees for complex artwork.

It also leaves traditional heat transfer vinyl (HTV) in the dust. Anyone who has spent hours weeding tiny pieces of vinyl and carefully layering colors knows the struggle. DTF eliminates all of that tedious work.

With DTF, what you see on your computer screen is exactly what you get on the final garment. It’s a straight shot from a digital file to a real, wearable product that feels great and holds up wash after wash without cracking or fading.

Ultimately, when you use ready-to-press DTF custom transfers, you’re skipping the most difficult and technical parts of the printing process. All you need is a heat press to bring your creations to life, letting you focus on what really matters: your designs and your business.

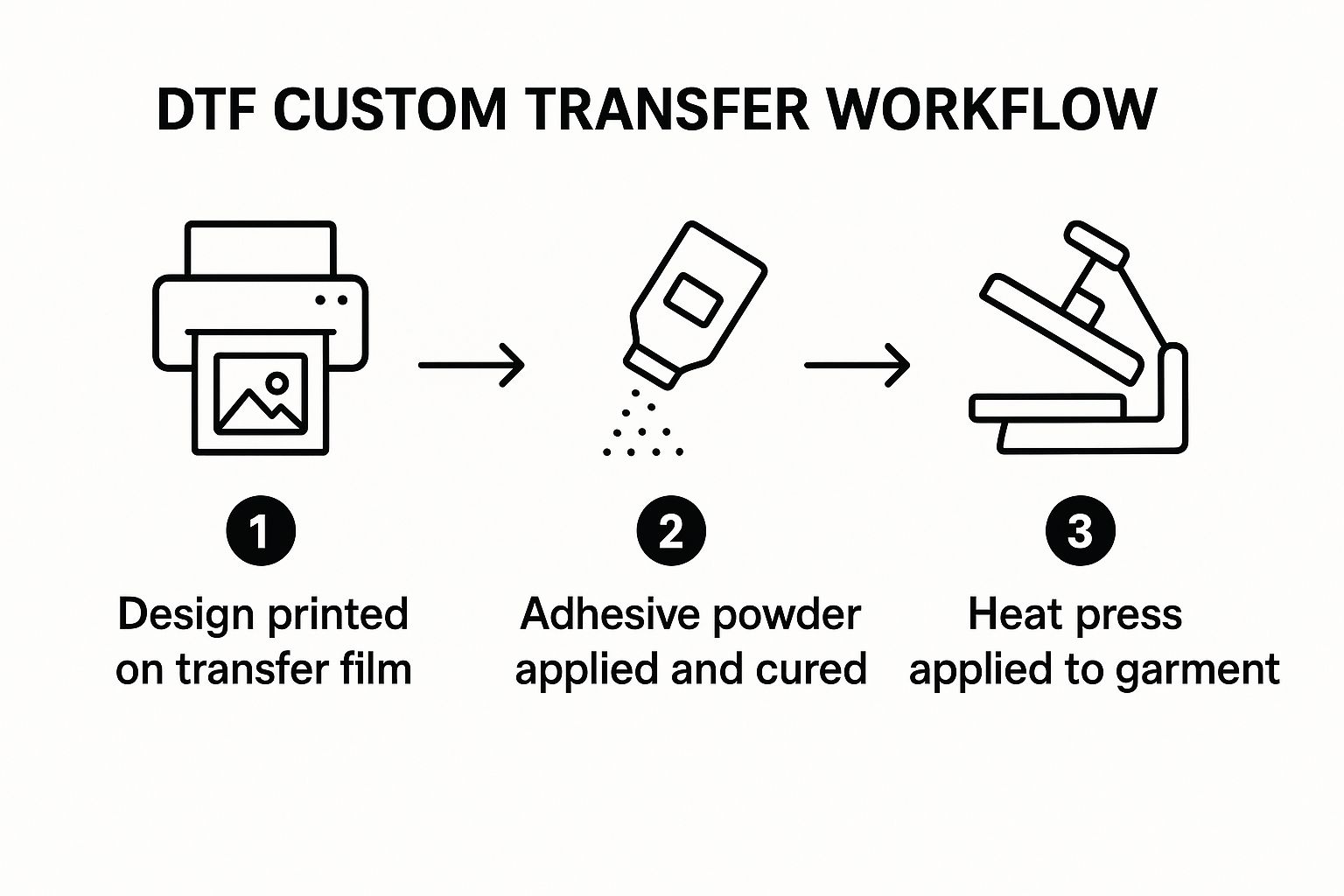

How a Digital Design Becomes a Wearable Print

Ever wonder how a design on a computer screen gets turned into a print you can wear? The journey from a digital file to a ready-to-press transfer is surprisingly cool and methodical. It all starts when your design is loaded into a specialized DTF printer. This isn't your standard office machine; it's a piece of equipment built specifically for this unique layering process.

First, the printer meticulously lays down the full-color CMYK (Cyan, Magenta, Yellow, and Black) layer of your design onto a sheet of clear PET film. The precision here is incredible, capturing every tiny detail from soft gradients to sharp, clean lines.

Right after the color goes down, the printer adds the most important part: a solid base of opaque white ink directly on top. This white underbase is the key to making dtf custom transfers pop on any color fabric, whether it's a dark hoodie or a brightly colored t-shirt. Without it, the colors would just sink into the fabric and look faded.

The Secret Ingredient: Adhesive Powder

With the ink layers down, the real magic happens. The printed film, still wet with ink, is coated with a fine, sugar-like thermoplastic polyurethane (TPU) adhesive powder.

This powder is clever—it only sticks to the wet ink of your design, leaving the rest of the film completely clean. Any extra powder is shaken off. The process is a bit like sprinkling glitter on glue; it only adheres where you want it.

Curing: Getting the Transfer Ready for You

The final step is to lock it all in. The powdered film is sent through a special curing oven, which melts the adhesive powder and fuses it directly to the ink. This turns the powder into a smooth, solid backing for your design.

This curing stage is what transforms the layered ink and powder into a professional, ready-to-use transfer. The melted adhesive is now a dormant glue, just waiting for a heat press to bring it back to life.

Once it cools, what you have is a vibrant, durable, and surprisingly flexible print on a clear sheet. The transfer is now finished and ready to be shipped out. All the complicated work is done. All that's left for you is the quick and easy part: pressing it onto your garment in just a few seconds.

The Real Benefits of Using DTF Transfers

So, what's all the buzz about? Why are so many apparel creators and print shops switching to DTF custom transfers? It really boils down to solving some of the oldest headaches in the garment-decorating world. We're talking about new creative doors opening up, and a smarter way to manage your money and inventory.

One of the biggest wins right off the bat is material freedom. For years, you had to play a matching game: screen printing for cotton, sublimation for polyester, and so on. It was a juggling act. DTF completely changes that game.

Now, you can take the very same transfer and press it onto a 100% cotton tee, a sleek polyester sports jersey, a tough canvas bag, or even a tricky nylon windbreaker. This isn't just convenient; it means you can offer a massive range of products without needing a different setup for each one.

Durability That Lasts

Let's talk about what happens after the customer takes their shirt home. The number one fear is that a beautiful design will crack, peel, or fade into a shadow of its former self after a few washes. DTF transfers are built to last.

The secret is the powerful adhesive that melts right into the fabric's fibers, creating a permanent bond. This makes the print feel surprisingly soft and light, but it’s also incredibly flexible. It stretches and moves with the garment, so it won’t crack under pressure. You can count on that design looking crisp and vibrant after wash 50, not just wash 1.

The true value of a DTF transfer lies in its ability to combine photorealistic detail with everyday resilience. It delivers the "wow" factor of a high-end print with the toughness needed for daily wear.

Cost-Effective for Any Size Order

This is where DTF really shakes things up financially. Old-school methods like screen printing are fantastic for huge runs, but the setup costs are a killer for small jobs. You have to burn a separate screen for every single color, which makes printing just a handful of shirts wildly expensive.

DTF throws that entire model out the window. Since it's a fully digital process, there are no screens and no minimum order quantities. This makes DTF custom transfers a perfect fit for so many scenarios:

- Testing new designs without sinking cash into a big inventory run.

- Creating personalized, one-of-a-kind items for individual customers.

- Handling small-batch orders for local businesses, bands, or events.

This "print-on-demand" power lets small businesses and solo creators punch above their weight, offering the same kind of variety as the big guys without the financial risk. For a deeper dive into how it compares to another popular digital method, check out our guide on DTF vs DTG printing.

DTF Transfers vs Other Printing Methods

To put it all into perspective, let's see how DTF stacks up directly against some of the most common printing methods you’ll encounter.

| Feature | DTF Custom Transfers | Screen Printing | Heat Transfer Vinyl (HTV) |

|---|---|---|---|

| Color Detail | Unlimited colors, photorealistic quality | Limited colors, one per screen | Limited to available vinyl colors |

| Fabric Versatility | Works on cotton, poly, blends, leather, nylon, and more | Best on cotton and blends, struggles with some synthetics | Good for cotton/poly, limited by fabric type |

| Feel on Garment | Soft, flexible, and lightweight | Can be thick and heavy, especially with many colors | Can feel like a plastic layer on the shirt |

| Durability | Excellent; resists cracking, peeling, and fading | Very durable, but can crack over time | Good, but can peel or lift at the edges |

| Small Orders | Very cost-effective, no minimums | Very expensive due to high setup costs | Feasible, but weeding complex designs is time-consuming |

| Setup Process | None; direct from digital file to print | Complex and time-consuming screen preparation | Design, cut, and weed vinyl before pressing |

Ultimately, while every method has its place, DTF custom transfers offer a unique combination of quality, flexibility, and affordability that is hard to beat for modern apparel decoration.

Bringing Your Creative Ideas to Life with DTF

This is where the rubber meets the road—where the science of dtf custom transfers becomes a real-world creative tool. The magic of this technology isn't just in the mechanics of it; it's in the amazing variety of projects it suddenly makes possible for everyone, from independent artists to established brands.

Imagine an artist who's been dreaming of launching their own clothing line. With DTF, their most intricate, multi-colored designs can be stamped perfectly onto t-shirts and hoodies, keeping every last detail of the original artwork intact. There are no color limits and no need to simplify your vision, which means true creative freedom.

From Local Teams to Growing Brands

Think about a local sports team. They need professional-looking jerseys but can’t justify the massive setup costs of traditional printing for a small run. DTF steps in as an affordable answer, letting them put durable names, numbers, and full-color logos onto polyester jerseys that will actually hold up on the field.

Or what about a neighborhood coffee shop that wants to sell some cool branded merch? Using DTF, they can order a small batch of transfers and press them onto tote bags, aprons, and hats as they need them. This on-demand approach means they can offer top-notch gear without tying up a bunch of money in inventory that might just sit on a shelf.

Pushing Creative Boundaries

But the real fun with dtf custom transfers starts when you think beyond basic apparel. This is where creative minds can really innovate and set themselves apart.

- Personalized Gifts: Think one-of-a-kind items like custom socks or hats for birthdays, holidays, and special events.

- Detailed Workwear: Get those sharp, clear logos onto tough work jackets, vests, and even high-visibility gear.

- Unconventional Items: Why stop at shirts? You can experiment by pressing unique designs onto canvas shoes, leather patches, or nylon bags.

The beauty of DTF is how it turns a simple idea into a high-quality, physical product. It's a direct bridge from a digital design on your screen to a wearable piece of art or a professional branding tool.

The demand for this kind of personalization is a huge driver in the apparel world. T-shirts alone accounted for 41% of market revenue in 2024, largely because people want unique, custom graphics. The global DTF printing market is even expected to reach USD 4.15 billion by 2032—a clear sign of how powerful this trend is. You can read the full research on the expanding DTF market to see the data for yourself. This growth really underscores the massive opportunity waiting for anyone ready to bring their ideas to life.

How to Achieve a Perfect Application Every Time

Getting a flawless, long-lasting print with dtf custom transfers isn't about luck—it's about precision. The process is surprisingly straightforward once you nail down a few key rules. By mastering these steps, you can sidestep the common pitfalls and get professional results, even on your very first try.

Your journey to a great print starts long before the heat press ever warms up. It begins with your artwork. Your digital file is the blueprint, and if it isn't perfect, your final print won't be either.

Always start with a high-resolution file, aiming for 300 DPI (dots per inch) to ensure every line is sharp and every color pops. A blurry or pixelated design file will only ever give you a blurry, pixelated transfer. It's also critical to submit your design with a transparent background; otherwise, any background color in the file will get printed right onto your garment, which is rarely the look you're going for.

Dialing in Your Heat Press Settings

Think of your heat press like an oven. For a cake to turn out perfectly, you need the right temperature, the right amount of time, and the right ingredients. The same logic applies here. The "ingredients" for a durable, professional-looking DTF print are temperature, pressure, and time.

Getting these three elements right is non-negotiable for creating a solid bond between the transfer and the fabric.

- Temperature: Most dtf custom transfers work best in the 300-325°F range. However, always double-check the recommended settings from your supplier, as this can vary based on the fabric you're printing on.

- Pressure: You're looking for firm and, most importantly, even pressure across the entire surface of the design. Uneven pressure is probably the number one reason transfers start peeling at the corners.

- Time: A typical press only takes 10-15 seconds. That’s just enough time to melt the adhesive and bond it to the fibers without scorching the garment.

A successful press is a science, not a guess. Inconsistent settings are the primary reason for application failures. Taking a moment to confirm your temperature, pressure, and time will save you from wasting transfers and garments.

The Final Steps Peeling and Aftercare

Once the timer goes off, how you peel the film is just as important as how you pressed it. Most transfers are "cold peel," which means you have to let the transfer cool down completely before you even think about removing the film.

If you peel it while it's still hot, you risk pulling the design right off with it. A little patience at this stage makes all the difference.

Finally, a little aftercare goes a long way. To give your print the longest life possible, wash the garment inside out in cold water and tumble dry on low heat. Avoiding high heat in the washer and dryer keeps the design looking crisp and vibrant for dozens of washes.

Want to see the quality and test the process for yourself? You can always get a free DTF transfers sample and put it to the test.

Your Top DTF Questions, Answered

Whenever you're looking into something new like DTF custom transfers, a lot of questions pop up. It's completely normal. Getting solid, straight-up answers is the best way to know if it's the right move for you. Let's walk through some of the most common questions we get day in and day out.

We'll tackle the big ones—how long they last, how to press them, what you can print on, and how many you need to order—so you can feel totally confident moving forward.

How Durable Are DTF Transfers Compared to Screen Printing?

This is the big one, right? The honest answer is that DTF custom transfers are incredibly durable. They easily go toe-to-toe with screen printing and, in many cases, will outlast it. When you press a DTF transfer correctly, its special adhesive melts right into the fabric, creating a super strong bond.

What you get is a print that moves and stretches with the garment without falling apart. It's engineered to fight off cracking, peeling, and fading, even after getting thrown in the wash dozens of times. That strong polyurethane adhesive really does its job.

Can I Use a Home Iron to Apply a DTF Transfer?

Look, I get the temptation, but please don't use a home iron. For a professional result that actually lasts, you absolutely need a heat press. A heat press delivers two critical things an iron just can't: consistent temperature and even pressure over the entire design.

An iron has hot spots and applies pressure unevenly, which is a recipe for disaster. You'll end up with corners that peel up and a transfer that fails way too soon.

A heat press is the only tool that properly cures the adhesive, locking it into the fabric for good. If you're serious about quality, investing in the right equipment isn't just a suggestion—it's essential.

What Kinds of Fabric Work Best with DTF Transfers?

Here’s where DTF really pulls away from the pack. Its versatility is just amazing. These transfers adhere beautifully to a massive range of materials, way more than most other printing methods can handle.

You can press them on pretty much anything:

- 100% Cotton

- 100% Polyester

- Cotton/Poly Blends

- Tri-Blends

- Nylon and Canvas

- Even tricky surfaces like leather

Think about it—sublimation is stuck with polyester, but DTF's unique adhesive process works on almost any item that can handle the heat. It just opens up a world of possibilities.

Is There a Minimum Order for DTF Custom Transfers?

For the most part, no! This is another huge win for DTF, especially for small shops, Etsy sellers, and independent brands. The whole process is digital, so there are no screens to burn or messy setups involved. It's built for printing on demand.

This means it's just as easy and cost-effective to print a single, one-of-a-kind design as it is to print a thousand of them. That kind of freedom is perfect for creating unique custom pieces or testing a new t-shirt idea without getting stuck with the high setup fees you see with screen printing.

Ready to see what American-made DTF transfers can do for your projects? Cobra DTF delivers vibrant, tough, and simple-to-use solutions with fast, dependable shipping.