DTF vs DTG Printing A Guide to Custom Apparel

Share

Deciding between DTF and DTG printing really boils down to a classic trade-off. DTF (Direct-to-Film) gives you incredible versatility and durability, letting you print on almost any fabric you can think of. On the other hand, DTG (Direct-to-Garment) delivers a super-soft feel with stunning detail on cotton, which is perfect for high-end, print-on-demand apparel.

The right choice really depends on what your business needs more: the flexibility to print on anything or the premium quality for specific garments.

Understanding the Fundamental Differences

At first glance, DTF and DTG might seem similar, but they're fundamentally different ways of getting a design onto a garment.

Think of DTG printing as an advanced inkjet printer for fabric. It sprays specialized inks directly onto the garment, where they soak into the fibers. This process is amazing for creating photorealistic images with millions of colors and smooth gradients. The end result feels incredibly soft and breathable because the ink is literally part of the shirt.

DTF printing, however, is a two-step transfer process. First, your design is printed onto a special PET film. This film is then coated with a powdered adhesive, cured with heat, and finally pressed onto the garment. This creates a durable, flexible design that sits on top of the fabric instead of soaking in.

The core distinction lies in the application. DTG ink becomes part of the fabric, while a DTF transfer bonds to its surface. This single difference influences everything from material compatibility and print feel to long-term durability.

Quick Look DTF vs DTG At a Glance

To help you get your bearings quickly, here’s a table breaking down the essential differences between the two methods. Use this as a starting point to see which technology aligns better with your needs before we dive into the nitty-gritty details.

| Feature | DTF (Direct-to-Film) | DTG (Direct-to-Garment) |

|---|---|---|

| Fabric Compatibility | Excellent (Cotton, polyester, blends, leather, nylon) | Limited (Primarily 100% cotton and high-cotton blends) |

| Print Feel | Flexible layer on top of fabric; slightly thicker | Soft, breathable; ink soaked into the fabric |

| Durability & Washability | Very high; resistant to cracking and fading | Good; can fade over time with many washes |

| Color Vibrancy | Excellent on all colors, including darks | Excellent, especially on light garments; requires pre-treatment for darks |

| Ideal Order Size | Small to large batches; highly scalable | Best for one-offs and small on-demand orders |

| Detail & Complexity | Great for bold graphics and solid colors | Superior for photorealistic images and fine details |

Ultimately, your decision will likely come down to your typical order size, the fabrics you use most, and your production speed and cost targets. DTG shines for small, on-demand jobs, while DTF’s versatility and durability make it a workhorse for a wider range of materials and larger batches. You can find more professional insights on these printing methods from industry leaders like Kornit.

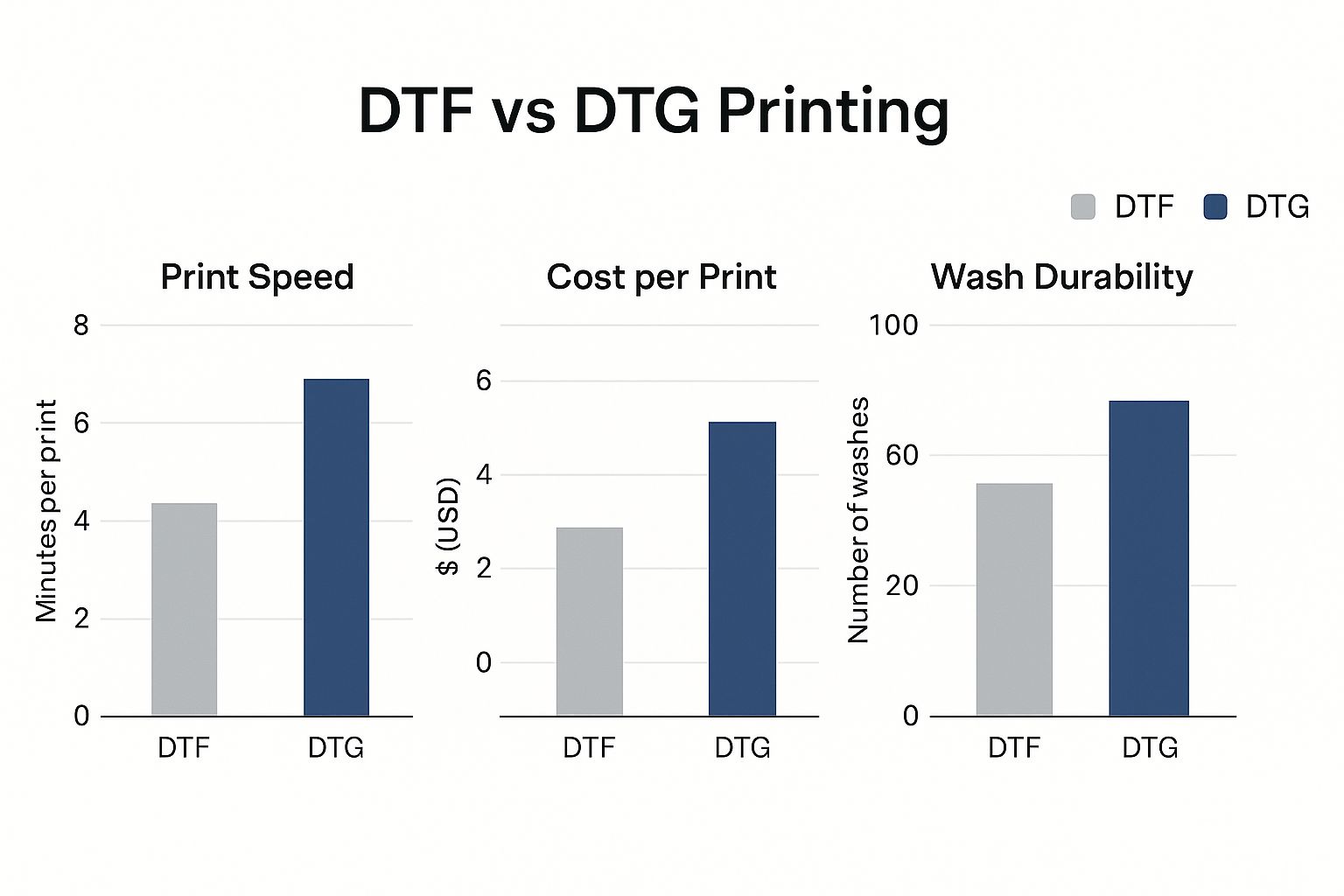

This next graphic helps visualize how the two stack up on key performance metrics like print speed, cost, and wash durability.

As you can see, DTF often takes the lead in wash durability and offers a lower cost per print, especially at scale. DTG, however, can be faster for one-off prints since it doesn't involve the multi-step transfer process.

How the DTF Printing Process Works

Direct-to-Film (DTF) printing has really taken the custom apparel world by storm, and for good reason. It’s all about the unique workflow. Unlike DTG, which prints right onto the fabric, DTF is an indirect method. This multi-step process is the secret sauce behind its incredible versatility and durability.

Everything starts with a specialized inkjet printer and DTF-specific inks. Your design gets printed not on paper or fabric, but onto a special polyethylene terephthalate (PET) film. This film is just a carrier, holding the ink perfectly until it’s ready for the garment. One of the clever efficiencies here is that the white ink underbase is printed at the same time as the color layer, which is a big improvement over older transfer methods.

Activating the Adhesive Layer

Once the design is on the film, it can't just be pressed onto a shirt. The next step is absolutely crucial: applying a special hot-melt adhesive powder. The still-wet ink gets a generous coating of this powder, which sticks only to the printed parts of your design. After a quick shake to remove the excess, you’re left with a precise adhesive layer that perfectly matches the graphic.

From there, the powdered film goes into a curing oven or under a heat press that hovers just above the surface. The heat melts the powder, turning it into a smooth, solid adhesive sheet that fuses with the ink. This is what creates the durable backing that will permanently bond your design to the garment.

The magic of DTF lies in this adhesive layer. It's the component that allows the transfer to stick to virtually any fabric—from cotton and polyester to leather and nylon—without the need for chemical pre-treatments.

The Final Transfer

Now for the main event—the transfer. You take the cured film, place it adhesive-side down on the garment, and press it with a heat press for about 8-12 seconds. The heat and pressure work together to reactivate the adhesive, forcing it to bond securely with the fibers of the fabric.

After pressing, you let it cool for a moment and then peel away the PET film. What’s left behind is a crisp, flexible, and surprisingly durable graphic. The print sits on top of the fabric, giving it a slightly raised but smooth feel that holds up incredibly well to washing and stretching.

This reliability and versatility are fueling some serious market growth. The global DTF printing market was valued at USD 2.72 billion in 2024 and is expected to keep climbing.

It’s this straightforward process that makes ordering ready-to-press DTF transfers so popular. It’s a great way for businesses to produce high-quality custom apparel on demand without having to invest in all the equipment themselves.

How the DTG Printing Process Works

Think of Direct-to-Garment (DTG) printing as a sophisticated inkjet printer, but built for fabric instead of paper. It works by applying specialized water-based textile inks directly onto the garment's surface. These inks are designed to soak into and bond with the cotton fibers, making the design a part of the shirt itself, not just a layer sitting on top.

This direct application is what gives DTG prints their signature soft-hand feel. When you run your hand over the design, you can barely feel it's there. This makes the final product incredibly breathable and comfortable to wear—a major point of difference in the DTF vs DTG printing debate, since DTF transfers create a distinct layer on the fabric.

The Critical Role of Pre-Treatment

Before any ink hits the fabric, there's a vital first step, especially when working with dark-colored apparel: pre-treatment. The garment is sprayed with a special liquid solution that acts as a primer, and it serves two critical functions.

First, it creates a smooth, uniform surface for the ink to sit on, preventing it from bleeding into the fibers and keeping the design's edges sharp. More importantly, it provides a foundation for the white ink underbase. Without pre-treatment, white ink would just get lost in dark fabric, leaving you with a dull, muddy-looking print.

After the pre-treatment solution is applied, the garment goes under a heat press to dry and set, creating the ideal canvas for printing.

Pre-treatment isn't optional for vibrant prints on dark garments. It's the essential step that allows DTG to deliver brilliant, opaque colors that really pop against black, navy, or any other deep shade.

Printing and Curing The Design

With the garment prepped and secured on the printer's platen, the real show begins. The DTG machine sprays microscopic droplets of ink, meticulously layering colors to bring the digital file to life with impressive precision. This is where DTG really shines—it's fantastic for photorealistic images, complex color gradients, and designs with a virtually unlimited color palette.

Once the ink is down, the job isn't done. The garment is carefully moved to the final stage: curing. It’s either sent through a large conveyor dryer or placed back under a heat press for a specific duration. This intense heat sets the water-based inks, permanently locking them into the fabric fibers to ensure the design is durable and can stand up to washing.

This ability to produce high-detail, one-off prints has made DTG a cornerstone of the print-on-demand world. In fact, the global Direct-to-Garment printing market was valued at USD 1.92 billion in 2024 and is expected to hit USD 3.90 billion by 2030, largely thanks to the boom in e-commerce and personalized goods. You can dive deeper into this trend by reading the full industry report. This incredible growth really underscores DTG's position as the go-to for businesses needing to turn around single orders quickly and cost-effectively.

Print Quality, Durability, and Feel: What's the Real Difference?

When you’re deciding between DTF and DTG, the final product is what really counts. Both technologies can create amazing-looking apparel, but they get there in different ways. The differences in quality, how long the print lasts, and how it feels to the touch are subtle but significant, and they can make or break your brand’s reputation.

Let's talk visuals. The "wow" factor of a print often comes down to its color and detail. This is where DTG really shines, especially for photorealistic images. Because the ink is absorbed directly into the cotton fibers, you get these beautiful, smooth gradients and a soft, matte finish. It’s hands-down the best choice for intricate, artistic designs on cotton.

On the other hand, DTF is all about punchy, bold color. The design is printed onto a film first, with a white base layer, so the colors sit right on top of the fabric. This method makes them incredibly vibrant and opaque, particularly on dark-colored garments. If you need a logo or a graphic to pop off the shirt, DTF delivers that slightly glossy, high-impact look.

Detail Reproduction on Different Fabrics

The fabric you choose will dramatically affect how much detail you can get. DTG is at its best on 100% ringspun cotton. The tight, smooth weave is the perfect canvas for capturing fine lines and complex textures without the ink bleeding. Try it on a looser weave or a poly-blend, and you might see some of that sharpness soften up a bit.

DTF, however, couldn't care less about the fabric's texture. Since the design is a self-contained transfer, it maintains its crispness and detail on a huge range of materials—polyester, nylon, blends, you name it. This makes DTF a far more reliable pick when you need sharp, consistent graphics across different types of apparel, especially performance wear.

The bottom line on quality really depends on the job. For that "no-feel" finish with incredible detail on a high-end cotton tee, DTG is unbeatable. But if you need guaranteed vibrant, sharp graphics on almost any material, DTF is the way to go.

How long will the print last? This is a huge deal for any apparel business, and the adhesive in the DTF process gives it a serious edge in the durability department.

DTF transfers are built to last. The melted adhesive powder forms a powerful, flexible bond that stretches right along with the fabric. This makes it incredibly resistant to cracking, peeling, and fading. A well-made DTF print can easily handle 50 or more washes and still look great—often outliving the garment itself.

DTG prints are durable, too, but they can be more prone to fading over time, especially if not cared for properly (think washing inside-out on a cold cycle). The constant friction in the wash can slowly wear away the ink-infused fibers. Still, a professionally cured DTG print on a quality cotton shirt will hold up for dozens of washes when treated right.

The All-Important "Hand Feel"

How a print feels to the touch is one of the quickest ways to tell DTF and DTG apart. This tactile experience is a massive deciding factor, depending on who you're selling to.

-

DTG Printing Feel: The ink literally becomes part of the fabric, leaving you with an unbelievably soft, breathable finish. On light-colored shirts where no white underbase is needed, you can’t even feel the print. This premium, "soft-hand" feel is exactly what fashion brands, baby apparel lines, and anyone prioritizing comfort is looking for.

-

DTF Printing Feel: The transfer sits on the surface of the fabric, creating a distinct layer. While modern DTF transfers are impressively thin and flexible, they have a smooth, almost rubbery texture. It’s very similar to a high-quality screen print transfer and is often perfect for workwear, jerseys, and promotional gear where durability trumps a soft feel.

Think of it this way: DTG is integrated, while DTF is applied. Neither is flat-out better; the "right" feel is all about what your product is designed to do.

Technical Showdown: DTF vs. DTG Performance Metrics

To make the comparison clearer, let's break down the technical performance side-by-side. This table gives you a quick snapshot of how each method stacks up in key areas.

| Performance Metric | DTF (Direct-to-Film) | DTG (Direct-to-Garment) | Best Use Case |

|---|---|---|---|

| Color Vibrancy | Excellent, high opacity on all fabrics and colors. | Superb on cotton, especially for gradients and photos. | DTF for bold logos on synthetics; DTG for art on cotton tees. |

| Wash Durability | Extremely high; rated for 50+ washes. Resists cracking. | Good; can experience gradual fading over many washes. | DTF for workwear and uniforms; DTG for fashion apparel. |

| Print Feel | Flexible layer on top of fabric; smooth but noticeable. | Very soft and breathable; ink is part of the fabric. | DTF for outerwear; DTG for premium t-shirts and baby clothes. |

| Detail Sharpness | Consistently sharp across all compatible materials. | Highest on smooth, 100% cotton fabrics. | DTF for branding on varied items; DTG for detailed illustrations. |

Ultimately, the DTF vs. DTG quality debate isn't about which is "better," but which is right for the job. You have to choose between DTF's incredible versatility and toughness versus DTG's premium, soft feel and photographic detail. The best choice is always the one that aligns with your specific garment, design, and the expectations of your customers.

Analyzing Cost and Production Efficiency

When you're trying to decide between DTF vs DTG printing, the conversation always comes back to money and time. Which one is cheaper? Which one is faster? The truth is, the right answer completely depends on your business model, order sizes, and how you run your shop.

Let's dig into the numbers and workflows to figure out which method really gives you the best bang for your buck.

The first hurdle is always the initial equipment cost, and this is where the two methods diverge significantly. A professional DTG printer is a serious piece of machinery, often setting you back tens of thousands of dollars. It's a major capital investment. A full DTF setup, on the other hand—which includes the printer, powder shaker, and a curing oven—can often be pieced together for a much lower entry price, making it far more approachable for startups.

But the sticker price of the machine is just the beginning. The real story of profitability is told through the ongoing costs of consumables.

Breaking Down Consumable Costs

With DTG, you're buying specialized, high-cost water-based inks. The real kicker, though, is the pre-treatment solution needed for any dark-colored garment. This chemical adds a direct cost and an extra step to every single dark shirt you print, which can really eat into your margins.

DTF works with a different set of supplies: PET film, hot-melt adhesive powder, and its own specific inks. While it sounds like more moving parts, the cost per print usually ends up being lower, especially when you're producing in volume. The inks are generally more affordable, and you completely skip the messy and expensive pre-treatment step.

This is why ordering pre-made transfers has become so popular. You can use a DTF transfers gang sheet builder to fit as many designs as possible onto one sheet, maximizing every square inch and driving your costs way down.

Here's the bottom line on cost: For a single, one-off print, DTG often wins because the setup is so direct. But as soon as you start printing in batches, DTF’s lower consumable costs and freedom from pre-treatment give it a powerful financial edge.

Comparing Production Workflow and Speed

Beyond the raw numbers, how each method fits into your daily workflow is just as important. Your efficiency determines your turnaround times and labor costs. Are you set up for one-at-a-time custom orders, or are you cranking out dozens of shirts for a local team?

Let's walk through two very different, but very common, scenarios.

Scenario 1: A Single Custom T-Shirt

If a customer walks in and wants one custom shirt right now, DTG is your hero. The process is incredibly direct: pre-treat if it's a dark shirt, load it on the platen, hit print, and cure it. You can have a finished product in hand in just a few minutes. It's built for that on-demand, instant gratification model.

Trying to make a single shirt with DTF feels clunky in comparison. You have to print on the film, apply the powder, melt it, and then press the transfer onto the shirt. For a one-off job, it's just plain slower.

Scenario 2: A Batch of 100 Shirts

This is where the tables turn completely, and DTF truly shows its strength. The "print now, press later" workflow is a massive advantage. You can run your DTF printer for hours, creating a huge roll of ready-to-press transfers.

When it's go-time, all you have to do is press them. This part is lightning-fast—often just 15-20 seconds per shirt.

Trying to produce 100 shirts with DTG is a slow, methodical grind. Each and every shirt has to be individually loaded, printed, and unloaded from the machine. The ability to batch the printing and pressing stages separately makes DTF infinitely more scalable for larger runs, slashing labor time and boosting your overall output.

Choosing the Right Technology for Your Niche

Okay, let's move past the technical specs. The real decision in the DTF vs DTG printing debate boils down to your business strategy. There isn't a single "better" technology; there's only the right tool for the job you need to do.

Think about your specific business goals, who you're selling to, and what products you plan to offer. By matching the strengths of each method to real-world scenarios, you can confidently pick the path that will actually help your brand grow. It's about making a smart investment that serves your niche.

When DTF Printing Is Your Best Bet

DTF really comes into its own in markets where versatility and toughness are key. Its power lies in its ability to stick to almost anything, making it a workhorse for businesses that need to brand more than just standard cotton tees.

Here are a few scenarios where DTF is the obvious choice:

- Sports Teams and Athletic Apparel: Most team uniforms are made from polyester or performance blends. DTF is perfect for this, creating crisp, durable logos and numbers that can stretch and take a beating without cracking or fading.

- Corporate Workwear and Uniforms: Think about companies that need branded polos, high-vis safety vests, or jackets. These items are often made from synthetics, and DTF delivers a consistent, professional look across the entire range.

- Band Merch and Promotional Gear: This is where DTF’s flexibility shines. Bands and event planners want to sell more than just shirts—they want hats, tote bags, and nylon drawstring bags. DTF handles all these different surfaces without a problem.

Bottom line: If your business model revolves around putting bold, long-lasting graphics on a wide variety of fabrics, especially synthetics, DTF is the clear winner. It's built for material diversity and handling larger runs.

When to Go with DTG Printing

On the other hand, DTG is the undisputed champ for high-detail designs with a super-soft feel, particularly for e-commerce brands and creative entrepreneurs. It excels when premium quality on cotton is what makes you stand out.

DTG absolutely dominates in these niches:

- Print-on-Demand E-commerce Stores: For online shops offering a huge catalog of designs without holding any inventory, DTG is the engine that makes it all possible. Its ability to produce a single, photorealistic print efficiently is the backbone of the modern dropshipping model.

- Artists and Illustrators Selling Graphic Tees: An artist’s work is all about the details—subtle shading, complex color gradients, and fine lines. DTG is really the only way to reproduce that level of complexity faithfully on a cotton t-shirt, giving you a true retail-quality product.

- One-of-a-Kind Custom Gifts: Think about businesses that create personalized gifts, like photo t-shirts for a family reunion or a custom-designed baby onesie. They depend on DTG's speed and precision for one-off jobs. Plus, that soft feel is crucial for anything meant for babies or kids.

Ultimately, this isn't just a tech decision—it's a market decision. DTF sets you up for volume and variety, while DTG empowers you to deliver premium, on-demand artistry.

Common Questions About DTF and DTG Printing

As you weigh the pros and cons of DTF vs. DTG, you're bound to have some lingering questions. Let's tackle a few of the most common ones that come up when people are trying to make that final decision. Getting these cleared up can really help you figure out which technology is the right investment for your business.

The feel of the final print is a huge one. It’s probably one of the most noticeable differences between the two methods and a major factor for customers.

Can You Feel the Print on the Shirt?

Absolutely, and the difference is night and day. DTG prints are famous for their incredibly soft, almost non-existent feel. The ink becomes part of the fabric itself, soaking right into the cotton fibers. On light-colored shirts, you can barely feel the design at all.

DTF is a different story. The print sits on top of the material, creating a thin, flexible layer. It feels smooth, a bit like a high-end vinyl or screen print transfer. This is exactly what makes DTF so durable and stretchy, but it's a distinct layer you can feel.

The right choice here often circles back to your brand. A luxury apparel line or a baby clothing brand would lean towards DTG for its unbeatable softness. But for durable workwear or vibrant promotional gear, DTF's tough, applied finish is a perfect match.

Which Is Better for a Small Business Starting Out?

Honestly, this really comes down to your specific business plan. For a lot of startups, DTF is the go-to recommendation. The initial equipment cost is generally lower, and its versatility is a massive selling point. If your goal is to print on everything from polyester jerseys and hats to tote bags and jackets, DTF gives you the freedom to take on almost any job that comes your way.

On the other hand, if you're launching a small online shop focused on intricate, artistic t-shirts made from 100% cotton, DTG might be your best bet. It’s built for the print-on-demand world, excelling at producing one-off, high-quality prints quickly and efficiently.

What Are the Main Maintenance Challenges?

Both printers need regular attention to keep them running smoothly—they aren't "set it and forget it" machines. DTG printers, especially those using white ink, are known for their demanding cleaning schedules. You'll need to stick to a strict daily and weekly routine to keep the print heads from clogging, which can lead to expensive repairs if neglected.

DTF systems have their own set of chores, mostly revolving around the powder and curing stages. You have to stay on top of the adhesive powder application to make sure it's even, and the curing temperature must be dialed in perfectly. Consistent quality depends entirely on getting this calibration right. To learn more about keeping your equipment in top shape, you can find a wealth of information in our DTF printing news and tips section.

At Cobra DTF, we specialize in providing top-tier, American-made DTF transfers that empower your business with vibrant, durable, and cost-effective printing solutions. Explore our premium DTF transfers today!