What Is DTF Printing Explained Simply

Share

Ever seen one of those super-detailed, vibrant graphics on a t-shirt and wondered how they did that? Chances are, you're looking at the work of a Direct-to-Film, or DTF, printer.

This technique is a game-changer for custom apparel. Essentially, we print a design onto a special transfer film, coat it with a powdered adhesive, and then use a heat press to transfer it onto the fabric. It’s like creating a high-end, super durable decal that literally becomes part of the garment.

What Is DTF Printing All About

Think of DTF as the perfect middle ground in the world of custom printing. It gives you the flexibility you'd get from simple transfer paper but with the professional quality of much more complex methods. And the best part? It's not picky about fabrics. DTF works brilliantly on everything from cotton and polyester to leather and blends, no matter the color.

The real magic is in the process itself, which is surprisingly straightforward.

- Step 1: Printing: First, a specialized printer lays down your design onto a clear PET film. It cleverly prints the vibrant colors and a solid white base layer all at once.

- Step 2: Adhesive Application: While the ink is still wet, a fine powdered adhesive is sprinkled over the entire design. This powder is the secret sauce that will permanently fuse your graphic to the garment.

Key Takeaway: The DTF process creates a finished, transferable design on film before it ever touches the fabric. This separation is what makes it so incredibly versatile, allowing it to work flawlessly on a huge range of materials, including dark-colored garments where other methods often fall short.

Finally, the film goes through a curing process where heat melts the adhesive powder, locking it into the ink. At this point, you have a ready-to-go transfer. A quick trip to the heat press is all it takes to release the design from the film and bond it permanently to the fabric. The end result is a soft, flexible finish that can handle dozens of washes without cracking or fading.

To help you get a clearer picture, here’s a quick breakdown of the essentials.

DTF Printing Quick Facts

| Component | Description | Key Benefit |

|---|---|---|

| PET Film | The special coated film the design is printed onto. | Holds ink perfectly and releases cleanly during transfer. |

| DTF Inks | Pigment-based inks, including a crucial white layer. | Creates vibrant, opaque designs on any color fabric. |

| Adhesive Powder | A fine, granular hot-melt powder. | Acts as the bonding agent between the ink and fabric. |

| Heat Press | The machine that applies heat and pressure. | Cures the adhesive and permanently bonds the design. |

This combination of components is what gives DTF its unique ability to produce high-quality, long-lasting prints so efficiently.

How the DTF Printing Process Actually Works

So, how does a digital file become a vibrant design on a t-shirt? Getting a handle on what DTF printing is becomes much easier when you walk through the actual process. It’s less of a single action and more like a step-by-step recipe, where each stage is crucial for that perfect, durable finish.

It all starts with a special piece of equipment: the DTF printer. This isn't your average office machine. It's built to work with specific textile inks and print onto a unique carrier sheet called PET film. The printer lays down your design in reverse, but here's the clever part: it simultaneously prints a base layer of white ink along with the colors.

That white ink layer is the secret sauce that makes the colors look so brilliant, even on a black shirt.

Step 1: Print and Powder

With the design printed on the film, and while the ink is still wet, we move to the next critical phase. A fine, white substance called hot-melt adhesive powder is sprinkled evenly over the entire printed area. The powder only sticks to the wet ink, perfectly outlining your design.

Any extra powder is shaken off, leaving a clean, powdered graphic. This "magic dust" is what will create the powerful bond between the ink and the fabric fibers.

Step 2: Curing the Transfer

Before it can be pressed onto a shirt, the powdered film needs to be cured. This is done by running it through a heat source, like a small curing oven, or by hovering a heat press just over the surface without touching it. The heat melts the powder, turning it from a grainy texture into a smooth, solid sheet that locks in the ink.

What you're left with is a completed, ready-to-press transfer. This stable graphic can be stored for later use, which is a huge advantage for businesses that need to print on demand.

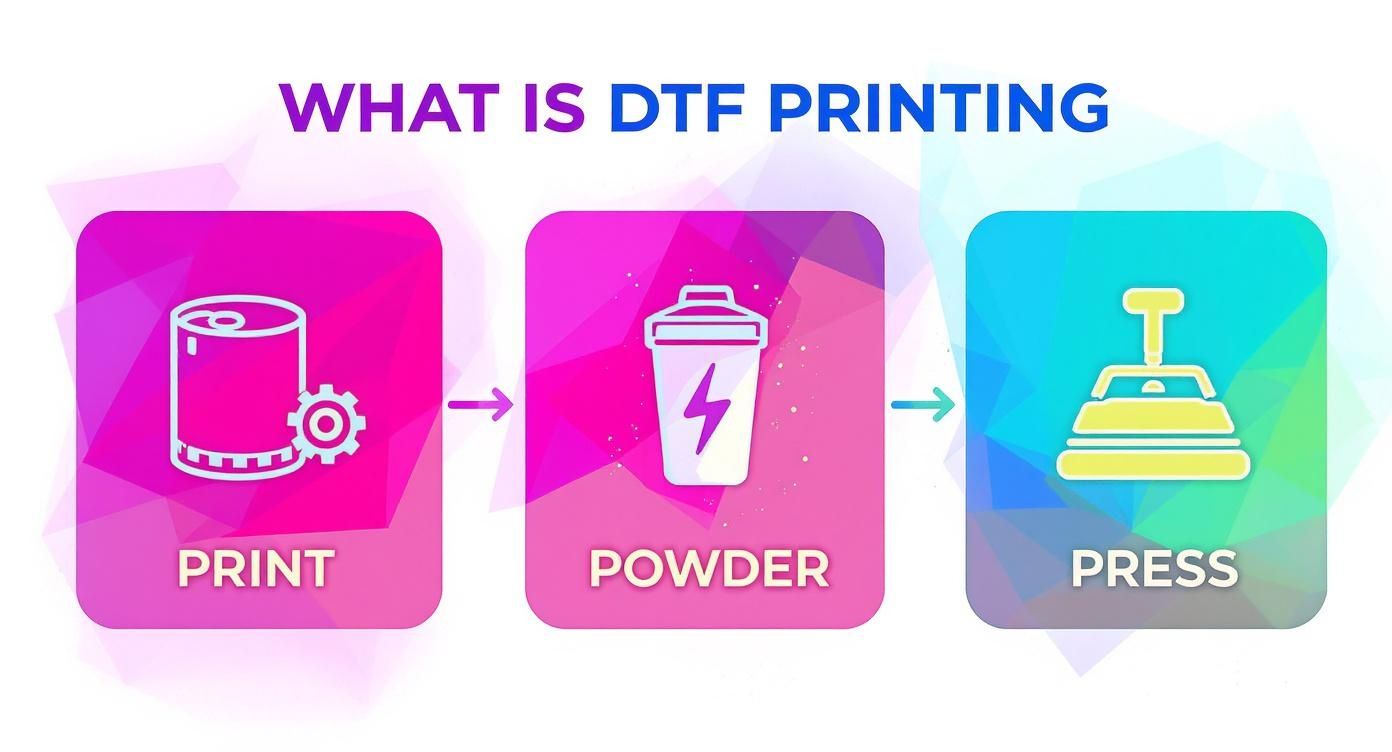

This infographic gives you a great visual breakdown of the three core steps in the DTF workflow.

It really simplifies the journey: printing on the film, adding the adhesive, and finally, pressing it onto the garment.

Step 3: The Final Heat Press

Now for the fun part—the transfer. The cured film is positioned on the garment exactly where you want the design. Then, a heat press applies just the right amount of heat and pressure. This reactivates the adhesive, causing the ink to permanently fuse with the fabric.

After a few seconds, you peel away the film, and all that remains is the soft, flexible, and stunningly vibrant design on the shirt. If you want to skip the printing and curing steps entirely, you can always order pre-made DTF custom transfers that are delivered ready for this final, simple press.

Why More Creators Are Choosing DTF Printing

The buzz around DTF printing isn't just hype—it's built on real-world advantages that solve some of the oldest headaches for apparel creators. Whether you're a small startup or an established brand, people are flocking to DTF for one huge reason: unmatched versatility.

Think about it. Other printing methods can be incredibly picky about fabrics. DTF, on the other hand, plays nice with just about everything—cotton, polyester, leather, and even tricky blends, regardless of the color. This means the same transfer can go on a dark cotton hoodie, a bright polyester jersey, or a canvas tote bag and look fantastic on all of them.

Unlocking Superior Quality and Feel

Beyond just working on more materials, DTF delivers a print quality that genuinely pops. The process captures photorealistic detail and a stunning spectrum of color, making even the most intricate designs look crisp and vibrant. The secret sauce is the white ink underbase, which acts as a primer to ensure colors stay bright and true, even on the darkest fabrics.

The finished product also feels great to the touch. DTF prints are soft and flexible, stretching with the fabric instead of creating that stiff, plastic-like patch you get with some older transfer methods. The garment doesn't just look amazing; it's comfortable to wear.

What really seals the deal for many is the durability. A properly applied DTF print is built to last, holding up through dozens of washes without cracking, peeling, or fading. It’s a professional-grade finish that customers can count on.

The Smart Choice for Business

Understanding why so many are adopting DTF can be a game-changer for anyone starting a fashion business. A major draw is how cost-effective it is, especially for small to medium-sized batches. You can skip the costly and time-consuming setup of screen printing, which makes on-demand orders and limited-edition drops incredibly profitable.

This practical accessibility is fueling explosive growth. The global market for DTF printing was valued at USD 2.56 billion in 2023 and is on track to hit an estimated USD 4.57 billion by 2033. That's a growth rate of nearly 6% every year, driven by the demand for customized apparel and a clear industry shift toward smarter digital solutions. For a deeper dive, you can explore more data about the growing DTF market at Spherical Insights.

DTF Printing Compared to DTG and Screen Printing

Picking the right printing method can feel like a tough choice, but it gets a lot easier once you know the core differences. When you're weighing DTF against Direct-to-Garment (DTG) and classic screen printing, you're really just figuring out the best tool for the job. Each one has a sweet spot where it truly shines.

DTF has emerged as the go-to jack-of-all-trades. It works on just about any material you can think of—cotton, polyester, blends, even leather—and on any color garment, all thanks to its solid white ink base. This versatility makes it ideal for anyone wanting to print on a diverse range of products, from t-shirts and hoodies to hats and bags.

Key Differences at a Glance

Screen printing is the old-school heavyweight, and for good reason. It’s still the undisputed king for massive orders with simple graphics. Think of it like a highly efficient stencil process; once you create the screens, you can crank out hundreds or thousands of identical prints very cost-effectively. The catch? The complex setup makes it a poor choice for small runs or designs with lots of colors.

DTG printing, on the other hand, works much like your desktop inkjet printer, but for clothes. It sprays ink directly into the fabric, giving the final print an incredibly soft feel with no texture. This is perfect for detailed, one-off designs on 100% cotton shirts. Its main limitations are that it doesn’t work well on polyester and can look dull on dark garments without careful pre-treatment.

If you want to get into the weeds on these two digital methods, check out our guide comparing DTF vs DTG printing for a more detailed look.

DTF really fills the gap between DTG and screen printing. You get the full-color, no-weeding convenience of DTG, but with the material flexibility and vibrant results on dark apparel that you'd typically associate with screen printing.

To make the comparison even simpler, let's break it down side-by-side.

DTF vs. DTG vs. Screen Printing

Here’s a head-to-head look at how these three popular printing methods stack up against one another.

| Feature | DTF Printing | DTG Printing | Screen Printing |

|---|---|---|---|

| Best For | Small-to-medium runs, various fabrics, detailed color graphics. | One-off prints, photorealism on 100% cotton. | Large bulk orders with simple, limited-color designs. |

| Fabric Type | Cotton, polyester, blends, leather, nylon (any color). | Primarily 100% cotton or high-cotton blends (best on light colors). | Most fabrics, but ink formulation may need to change. |

| Print Feel | Soft, flexible, and sits on top of the fabric. | Extremely soft, as ink soaks directly into fibers. | Can be thick and heavy, especially with multiple colors. |

| Durability | Excellent wash resistance; won't crack or fade easily. | Good, but can fade over time with repeated washing. | Extremely durable, often outlasting the garment itself. |

As you can see, the best choice really depends on what you're trying to create. DTF stands out by offering a powerful combination of quality, versatility, and efficiency that fits the needs of most modern print shops.

Real-World Applications of DTF Printing

The best way to really grasp what DTF printing can do is to see it in the wild. Its sheer flexibility creates a huge playground for businesses and creators alike. Whether you're an entrepreneur launching a clothing brand from your garage or an event manager needing last-minute promo gear, DTF delivers clean, professional results every time.

One of the biggest areas, of course, is custom apparel and fashion. Small businesses can now print complex, full-color designs on t-shirts, hoodies, and jackets without the steep setup fees that come with traditional screen printing. Fashion designers are also turning to DTF to apply intricate patterns to tricky materials like polyester and leather. Just remember, before you hit "print," getting a handle on the basics of designing for print layouts will make a world of difference in your final product.

Expanding Beyond Apparel

But it's a mistake to think DTF is just for clothing. This technology is fantastic for creating all kinds of promotional merchandise and unique accessories.

- Team Sports and Events: Since it produces such vibrant, long-lasting prints on polyester, DTF has become the go-to for team jerseys, athletic gear, and staff uniforms.

- Promotional Products: Companies use it to put their logo on tote bags, hats, aprons, and even umbrellas, knowing the design won’t crack or peel after a few uses.

- Hard-to-Print Items: DTF can also tackle items that other methods can't, like shoes and backpacks. There's even a specialized process for hard surfaces, which you can read about in our guide to https://cobradtf.com/blogs/guides/uv-dtf-printing.

This incredible versatility is what's driving its massive growth. The global DTF printing market was valued at around USD 2.72 billion in 2024 and is on track to hit nearly USD 3.92 billion by 2030.

That boom is all thanks to the growing demand for personalized products and the simple fact that DTF technology is so cost-effective.

Common Questions About DTF Printing

Jumping into any new printing method brings up a few questions. If you're exploring DTF, you're probably wondering about durability, what kind of gear you need, and what the final product actually feels like. Let's clear up some of the most common questions people have.

How Long Do DTF Prints Actually Last?

This is probably the number one question we hear, and for a good reason. The great news is that a well-made, properly applied DTF transfer is built to last. You can expect it to hold up for 50 to 100 washes, which often means it will outlive the t-shirt it's printed on.

Unlike some other methods that can crack, peel, or fade after just a few trips through the laundry, DTF prints are incredibly resilient. For the best results, just wash the garment inside out with cold water and either tumble dry on low or let it hang dry. That’s it.

Can I Just Use My Regular Printer for DTF?

It’s a common thought, but unfortunately, the answer is a firm no. Your standard office or home inkjet printer just isn't built for the job. DTF printing relies on a completely different set of tools and materials to get that professional-grade result.

Here’s what makes a true DTF setup unique:

- Specialized DTF Printers: These machines are designed to handle specific textile inks and, most importantly, have a dedicated channel for white ink—something your desktop printer doesn't have.

- DTF Inks: The ink itself is a special pigment-based formula designed to be flexible and bond permanently to fabric.

- PET Transfer Film: This isn't just any clear sheet; it's a special film engineered to hold the ink and release it perfectly under heat.

- Adhesive Powder: This is the magic ingredient. This fine powder melts during the curing process, acting as the glue that fuses the ink to the fabric.

- RIP Software: This specialized software is the brain of the operation, telling the printer exactly how to lay down the color and white ink layers for a vibrant, opaque print.

Trying to rig a standard printer just won't work and will lead to frustrating, low-quality results.

What Does a DTF Print Feel Like on a Shirt?

People are often worried the design will feel thick, heavy, or plastic-like. With DTF, that’s not the case at all. The finished print has a smooth, soft-hand feel that's surprisingly lightweight. It sits on the surface of the fabric, but it’s far more flexible and comfortable than the heavy vinyl transfers of the past.

The design moves and stretches with the fabric, so it never feels like a stiff decal. It's a clean, premium finish that works great on all sorts of apparel.

The explosive growth of DTF, especially in North America, really speaks to its quality. The United States is leading the charge, and the market is expected to grow at a CAGR of 5.5% between 2025 and 2032. Much of that growth comes from small businesses and entrepreneurs who need a reliable, high-quality, and cost-effective way to create custom apparel. You can read more about the North American DTF printing market on kbvresearch.com.

Ready to see what premium DTF can do for your projects? Cobra DTF provides vibrant, durable, and ready-to-press transfers made right here in the USA. Skip the equipment investment and get perfect prints every time by visiting us at https://cobradtf.com.