Choosing Your T Shirt Printing Technique

Share

So, you've got a fantastic design and you're ready to bring it to life on a t-shirt. Welcome to the world of custom apparel! The secret to a killer final product isn't just the artwork—it's picking the right t-shirt printing technique. Think of it like a skilled chef choosing the right tool for the job; the best method really depends on your design's complexity, how many shirts you need, the fabric you're using, and your budget.

This guide will walk you through the most popular options out there, breaking them down so you can make sure your vision becomes a reality, exactly as you imagined it.

How to Choose Your Perfect Printing Method

Nailing down your printing method is the first real step toward creating custom apparel that not only looks professional but also lasts. Each technique works with fabric in a totally different way, giving you a unique look, feel, and level of durability. Getting this right from the start helps you dodge common headaches like faded designs, peeling graphics, or a final bill that's way higher than you expected.

It’s all about matching the tool to the task. You wouldn't use a tiny artist's brush to paint a whole wall, right? The same idea applies here. One method might give you a vibrant, tough-as-nails finish that's perfect for a big run of event merch, while another is the go-to for printing a single, photorealistic design on a one-of-a-kind shirt.

Understanding the Key Factors

Before we get into the nitty-gritty of each technique, let's zoom out and look at the big-picture factors that will steer your decision. Thinking through these upfront will save you a ton of time, money, and frustration later on.

Here’s what you need to have in mind:

- Design Complexity: How many colors are in your design? Is it full of tiny details, smooth gradients, or even a photograph?

- Order Quantity: Are you making just one special shirt for yourself, or are you gearing up for a bulk order of 500+ for your brand or a big event?

- Fabric Type: The material of your garment is a huge deal. Some printing methods are best friends with 100% cotton, while others are made for polyester or work great on blends. You can dive deeper with our guide on choosing the right t-shirt fabric material for more on that.

- Desired Feel: How do you want the final print to feel? Are you after something super soft that feels like part of the fabric, or do you prefer a bolder, slightly raised texture that you can feel?

By carefully balancing these four elements—design, volume, fabric, and feel—you can confidently pick the t-shirt printing technique that perfectly matches what you're trying to achieve.

A Booming Industry of Customization

The appetite for personalized apparel is bigger than ever. This boom is fueled by everyone from small businesses building a brand to individuals who just want to wear something that’s uniquely them. It's a massive market—the global custom t-shirt printing industry is set to rocket from $8.17 billion in 2024 to an incredible $13.55 billion by 2029.

This explosive growth just goes to show how important it is for creators, designers, and entrepreneurs to really understand the tools they have at their disposal. You can see more stats on this expanding market on GlobeNewswire.

The Classic Method: Screen Printing Explained

Screen printing is the undisputed heavyweight champion in the world of custom t-shirts. It's a time-tested technique known for creating vibrant, rock-solid designs that feel like they'll last forever. If you’ve ever owned a band tee or a university hoodie with a bold, slightly raised graphic, you've almost certainly seen its quality firsthand. For good reason, it’s the go-to method for large-scale production runs.

Think of it like creating a multi-layered painting, but instead of using a paintbrush, you're using a series of highly detailed stencils. At its heart, that’s screen printing. A fine mesh screen is stretched taut over a frame, and a stencil of your design is burned into it, blocking out areas where you don't want ink to pass through.

For a design with, say, three different colors, you’d need three separate screens—one for each color. Ink is then pushed through the open mesh of the stencil and onto the t-shirt with a tool called a squeegee. This process gets repeated for each color, one layer at a time, until the full design comes to life.

Why Screen Printing Is Still an Industry Standard

So, why has this method stuck around for so long? It all comes down to a few key strengths, especially when you need to print a lot of shirts at once. Once the initial setup is done, the process is incredibly efficient.

This kind of efficiency is crucial in the custom apparel world, which is a massive global industry. With over 2 billion t-shirts sold every year, production methods have to be reliable. It’s also why the print-on-demand market is projected to grow at a compound annual rate of about 26% through 2034. You can dig deeper into these apparel industry trends on Goodink.com.

The key benefits that keep screen printing at the top of its game include:

- Cost-Effective at Scale: The upfront cost of making the screens gets spread out over hundreds or thousands of shirts, dropping the price per item way down on bulk orders.

- Built to Last: Screen printing ink cures and chemically bonds with the fabric. This creates a print that’s incredibly tough, resisting fading, cracking, and peeling through countless wash cycles.

- Vibrant, Punchy Colors: This technique lays down a thick, solid layer of ink. The result is super bright, opaque colors that really pop, especially on dark fabrics.

The real magic of screen printing is its economy of scale. Setting up for just one shirt is wildly expensive, but printing 500 of them becomes remarkably affordable. That's why it's the top choice for band merch, company uniforms, and event apparel.

Understanding the Limitations

As great as it is, screen printing isn't the right tool for every job. The very process that makes it so good for bulk orders also creates some specific drawbacks you need to know about.

Its biggest hurdle is the setup. Creating a separate screen for every single color in a design is both time-consuming and expensive. This makes it a terrible choice for photorealistic images or designs that are packed with different color gradients.

Keep these limitations in mind:

- High Setup Costs: It’s just not practical for small batches or one-off prints. The cost to create a handful of screens for a single shirt would be astronomical.

- Limited Color Complexity: Designs with smooth gradients or photographic details are tough, if not impossible, to get right. This method really shines with bold, solid colors.

- The "Feel" of the Print: Because the ink sits on top of the fabric, the final print has a distinct texture—sometimes it can feel a bit thick. This might not be what you want if you're going for a super-soft, breathable feel where the design feels like part of the shirt itself.

The Digital Revolution: Direct-to-Garment (DTG)

If screen printing is the classic workhorse of the apparel world, then Direct-to-Garment (DTG) is the specialized digital artist. It’s best to think of it like a highly advanced inkjet printer, but instead of feeding it paper, you load a t-shirt. This t-shirt printing technique uses water-based inks that are sprayed directly into the fibers of the garment, allowing for jaw-droppingly detailed, full-color designs.

Because the ink soaks right into the fabric instead of sitting on top of it, the final print has an incredibly soft feel. There's almost no texture to speak of; it feels like it’s a natural part of the shirt. This direct-application process is what allows DTG to replicate smooth gradients, subtle shading, and even photorealistic images with millions of colors—something old-school methods just can't pull off.

The Power of Printing Just One

The single biggest game-changer with DTG is the lack of setup costs. Screen printing demands expensive, custom screens for every single color in a design. A DTG printer, on the other hand, can produce a complete, full-color masterpiece in a single pass. This makes it the undisputed champion for one-off prints and small orders.

This exact capability is what fueled the entire print-on-demand industry. It gives artists and small brands the freedom to sell unique designs without ever having to risk a dime on a huge inventory. It’s perfect for testing out a new t-shirt idea or creating a truly personalized gift.

Here’s where DTG really shines:

- Unlimited Color Palette: You can print designs with millions of colors, making it the perfect choice for photographs, intricate illustrations, and complex artwork.

- Exceptional Detail: Fine lines, delicate text, and subtle color shifts are all reproduced with incredible accuracy.

- Soft-Hand Feel: Since the ink becomes part of the fabric, the print is comfortable, breathable, and doesn't have that heavy, plastic-like feel.

- No Minimum Orders: You can print one shirt just as easily as you can print a dozen, offering amazing flexibility for creators.

Knowing the Limitations

While DTG is an incredible tool, it’s not without its weak spots. The process and its water-based inks mean it really only performs at its best under specific conditions. For starters, the whole technique is highly dependent on what the shirt is made of.

DTG works best on 100% cotton fabrics. Why? Because the natural fibers do an amazing job of absorbing the water-based inks. While you can get decent results on some high-cotton blends, its performance on synthetics like polyester is generally poor, often leaving you with a faded or splotchy print. Also, if you’re printing on a dark-colored shirt, a white underbase layer has to be printed first to make the colors pop. This extra step can slightly change how the final print feels.

To see a direct comparison, you can explore our in-depth analysis of DTF vs. DTG printing.

DTG is the go-to choice for artists and print-on-demand sellers who prioritize detail and color complexity over bulk production speed. It's the perfect method for turning digital art into wearable art.

The Rise of Digital Printing

The clear advantages of digital methods like DTG are reshaping the custom apparel industry. This segment is projected to grow by an impressive 12.5% annually between 2025 and 2030, a trend driven by faster production times, lower costs for small runs, and some major environmental benefits.

For instance, digital printing techniques can slash water consumption by up to 90% compared to traditional dyeing and printing processes. You can discover more insights about these t-shirt industry statistics on Printful.com.

This shift points to a growing demand for a more efficient and sustainable t-shirt printing technique. DTG is at the forefront of this movement, offering a high-quality solution that meets the needs of a new generation of creators and consumers. It delivers unmatched detail for complex designs on cotton, cementing its place as an essential tool in modern apparel customization.

Enter Direct to Film (DTF) Transfers

While screen printing is a workhorse and DTG excels at detail, a new player has stepped onto the field, cleverly borrowing the best traits from both. Direct to Film, or DTF, is a powerful hybrid t-shirt printing technique that’s quickly becoming a favorite for its sheer versatility and knockout results. It neatly sidesteps many of the headaches found in other methods, making it a serious contender for modern print shops.

Unlike DTG, which prints right onto the shirt, DTF uses a clever two-step process. First, your design is digitally printed onto a sheet of special PET transfer film. The best way to think of it is like creating a high-quality, full-color temporary tattoo for your apparel. This initial step captures all the intricate details and unlimited colors you'd expect from a top-tier digital printer.

Once the design is on the film, the real magic begins.

The Secret is the Adhesive Powder

After the ink is laid down on the film, a fine layer of powdered adhesive gets sprinkled over the wet ink. This powder is the key ingredient in the DTF recipe. The film then takes a trip through a small curing oven, where the heat melts the powder and fuses it directly to the ink. This creates a single, durable, and surprisingly flexible transfer.

Now, this ready-made transfer can be applied to almost anything. You simply position it on the t-shirt and press it with a heat press. The heat activates the adhesive, permanently bonding the design to the fabric. Peel away the film, and you're left with a crisp, vibrant graphic that feels soft and has a great stretch to it. A huge bonus? This process completely gets rid of the need for pre-treating fabric, a messy but necessary step when using DTG on dark garments.

The image below from Cobra DTF shows just how sharp and colorful these transfers can be.

What you’re seeing is the incredible sharpness and color pop that’s possible with DTF, which is exactly what you need to create professional-looking clothes.

Print on Almost Anything

One of the biggest reasons people are switching to DTF is its incredible ability to work with all sorts of materials. While DTG printers are notoriously picky and work best with 100% cotton, DTF transfers can be pressed onto a massive range of fabrics with fantastic results.

This opens up a whole new world for apparel businesses. You can use the exact same DTF transfer for:

- Cotton and Cotton Blends: The classic t-shirt materials? No problem.

- Polyester: Perfect for athletic jerseys, performance wear, and team apparel.

- Nylon and Fleece: Think jackets, hoodies, and cozy outerwear.

- Even Leather and Canvas: The possibilities go way beyond just t-shirts.

This "print on anything" capability makes DTF an incredibly efficient t-shirt printing technique for shops that sell a variety of products. You can run one machine to serve a huge range of customer requests, from basic cotton tees to specialized performance gear.

DTF’s genius is in its indirect approach. By creating the print on a film first, it sidesteps the fabric compatibility issues that handcuff other printing methods. It’s a true jack-of-all-trades.

How DTF Stacks Up

When you put DTF side-by-side with the others, its unique advantages really shine. It gives you the full-color, photorealistic detail of DTG but frees you from the fabric restrictions. It also provides a much more durable and flexible feel than a lot of old-school heat transfer vinyls, which can feel thick on the shirt and are known to crack over time.

Screen printing is still the king for massive orders of simple, one- or two-color designs. But for small-to-medium-sized runs with complex, multi-color art, DTF is often much more cost-effective. There are no screens to burn and no lengthy setup, so you can fire out varied designs quickly and efficiently. This makes DTF a game-changer for businesses looking for that perfect mix of quality, flexibility, and speed.

Comparing Each T Shirt Printing Technique

Now that we’ve covered the basics of each method, it's time to see how they stack up against one another. Choosing the right t shirt printing technique isn't as simple as picking from a list of pros and cons. It’s really about finding the perfect tool for the job you have in mind.

Think about it this way: if you're launching a streetwear brand with a limited-edition drop featuring a photorealistic design, DTG or DTF is your best friend. They excel at detail without demanding huge order quantities. But if you’re outfitting a team for a 500-person charity run, screen printing is the undisputed champ. Its cost-per-shirt drops dramatically as the order size goes up, giving you the best bang for your buck.

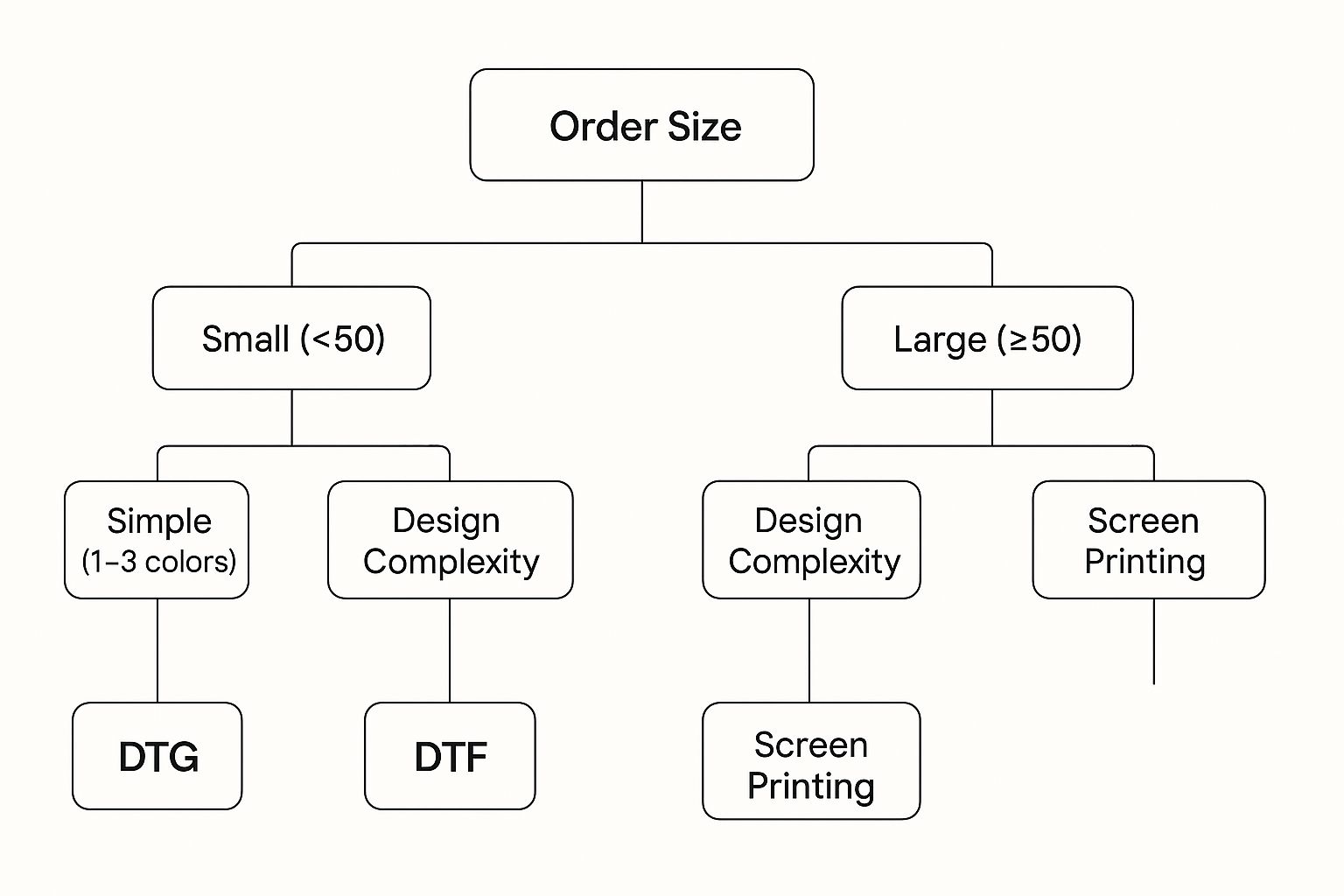

This visual guide can help you figure out which path makes the most sense based on how many shirts you need and how complex your design is.

When it comes down to it, order volume and design detail are the two biggest factors that will point you toward the most efficient and high-quality option for your project.

Diving Deeper: The Key Differences

To really make the right call, let’s get into the nitty-gritty details that set these methods apart. Understanding these factors helps you predict not just the cost, but the final look and feel of your apparel.

- Cost-Per-Shirt: Screen printing is a volume game—the more you print, the cheaper it gets. DTG and DTF have a more stable price per piece, which makes them perfect for smaller batches.

- Vibrancy and Color: If you want colors that pop right off the fabric, DTF and screen printing are your go-to. Their inks sit on top of the shirt. DTG ink, on the other hand, soaks into the fibers for a softer, more integrated look.

- Durability and Feel: Screen printing creates a classic, durable print that you can feel. DTG is the opposite—it’s so soft you can barely feel it. DTF strikes a great balance, offering a smooth, flexible finish that’s built to last without cracking.

- Fabric Compatibility: This is where DTF really shines. It works on just about anything—cotton, polyester, blends, you name it. DTG is a cotton purist, while screen printing handles most common t-shirt fabrics with ease.

At the end of the day, the "best" technique is the one that fits your needs. It's a combination of your design, order size, fabric choice, and the final vibe you're going for. There’s no single right answer for every job.

Detailed T-Shirt Printing Method Comparison

To make things even clearer, here’s a side-by-side breakdown. This table is a great cheat sheet for weighing your options based on what matters most for your specific project.

| Factor | Screen Printing | DTG (Direct-to-Garment) | Heat Transfer Vinyl (HTV) | DTF (Direct-to-Film) |

|---|---|---|---|---|

| Best For | Large bulk orders (50+) with simpler designs | Small orders, one-offs, and photorealistic art | Names, numbers, and simple, bold graphics | Small to large runs with complex, vibrant art on any fabric |

| Durability | Excellent: Cured ink is extremely tough. | Good: Can fade slightly over time with many washes. | Good: Can crack or peel if not applied or cared for properly. | Excellent: Flexible and highly resistant to cracking and fading. |

| Feel | Slightly thick and raised on the fabric. | Very Soft: Ink soaks into fibers, minimal texture. | A distinct layer on top of the fabric. | Smooth and flexible, sits on top of the fabric. |

| Color Pop | Very vibrant and opaque. | Great detail, but can be less punchy on darks. | Extremely bold and opaque. | Exceptionally vibrant with a bright white underbase. |

| Fabrics | Cotton, blends, some polyesters. | Best on 100% cotton; struggles with synthetics. | Cotton, polyester, and blends. | Works on virtually everything: cotton, poly, blends, and more. |

This table gives you a great overview, but sometimes the real devil is in the details.

If you’re trying to decide between the classic approach and newer transfer methods, dive into our detailed guide comparing silk screen printing vs heat transfer techniques to get an even more focused perspective.

T-Shirt Printing Questions Answered

Diving into the world of custom t-shirts can feel a bit overwhelming. You’ve got options, and each one has its own quirks. To help you feel confident in your choice, we've tackled some of the most common questions people ask when picking a printing technique. This should clear things up and help you find the perfect match for your project.

Every method brings something different to the table in terms of how long the print lasts, how it feels on the shirt, and what it costs. Getting a handle on these real-world differences is the last piece of the puzzle to make sure your design turns out just right.

What’s the Most Durable T-Shirt Printing Technique?

If you're looking for a print that will outlast the shirt itself, screen printing has long been the gold standard. The ink essentially becomes one with the fabric, creating a tough design that stands up to countless wash cycles without a fuss. It’s built for the long haul.

That said, newer methods are giving it a serious run for its money. Direct-to-Film (DTF) is an incredibly close second, offering fantastic durability with a bit more flexibility. DTF transfers are made to stretch and resist cracking or fading, making them a remarkably tough choice for just about any kind of apparel.

Which Printing Method Is Best for Small Orders?

When you only need a handful of shirts—or even just one—you can't beat Direct-to-Garment (DTG) and DTF. Because they're digital, you don't have to worry about hefty setup fees. You can print one shirt as easily as you can print twenty.

In contrast, screen printing involves creating a separate screen for every single color in your design. That process gets expensive fast for small runs but becomes incredibly cost-effective when you're ordering hundreds of shirts and can spread that setup cost out.

Can You Print Photorealistic Images on a T-Shirt?

Absolutely! This is where DTG printing really stands out. Imagine a super-advanced inkjet printer designed to work on fabric, and you've got the right idea. It can flawlessly reproduce millions of colors, tiny details, and the subtle color gradients you need for a stunning photo. DTF is also a phenomenal choice for getting photo-quality prints with incredibly bright, punchy colors.

What’s the Core Difference Between DTG and DTF?

The main distinction is how the ink gets onto the shirt. It really boils down to in versus on.

- DTG (Direct-to-Garment): Think of this as ink being injected directly into the cotton fibers. It uses water-based inks that soak into the fabric, leaving you with a super soft, breathable print that feels like part of the shirt. This works best on 100% cotton.

- DTF (Direct-to-Film): With this method, the design is first printed onto a special transfer film. Then, that film is heat-pressed onto the surface of the shirt. This simple but brilliant process means it works on almost any material—polyester, cotton, blends, you name it—and often produces bolder, more vibrant colors, especially on dark fabrics.

Ready to bring your complex, vibrant designs to life on any fabric? Trust the experts at Cobra DTF for high-quality, USA-made transfers that ship fast and deliver professional results every time. Explore our premium DTF solutions today.