Silk Screen Printing vs Heat Transfer Guide

Share

When you're trying to decide between silk screen printing and heat transfer, it really boils down to this: screen printing is your workhorse for large, simple orders, while heat transfer shines for small runs of complex or personalized designs. It’s a classic trade-off: do you need the durability and cost-efficiency of a bulk order, or the creative freedom to print detailed, full-color images on demand?

Comparing Silk Screen and Heat Transfer

Picking the right printing method is a huge decision for any small business that makes custom apparel. It's not just about how the final product looks; it impacts your budget, how fast you can produce items, and how long your designs will last. Silk screen printing is a classic, battle-tested technique, whereas heat transfer gives you modern flexibility. Getting to the heart of their differences is the first step in making a smart choice that actually fits what you're trying to accomplish.

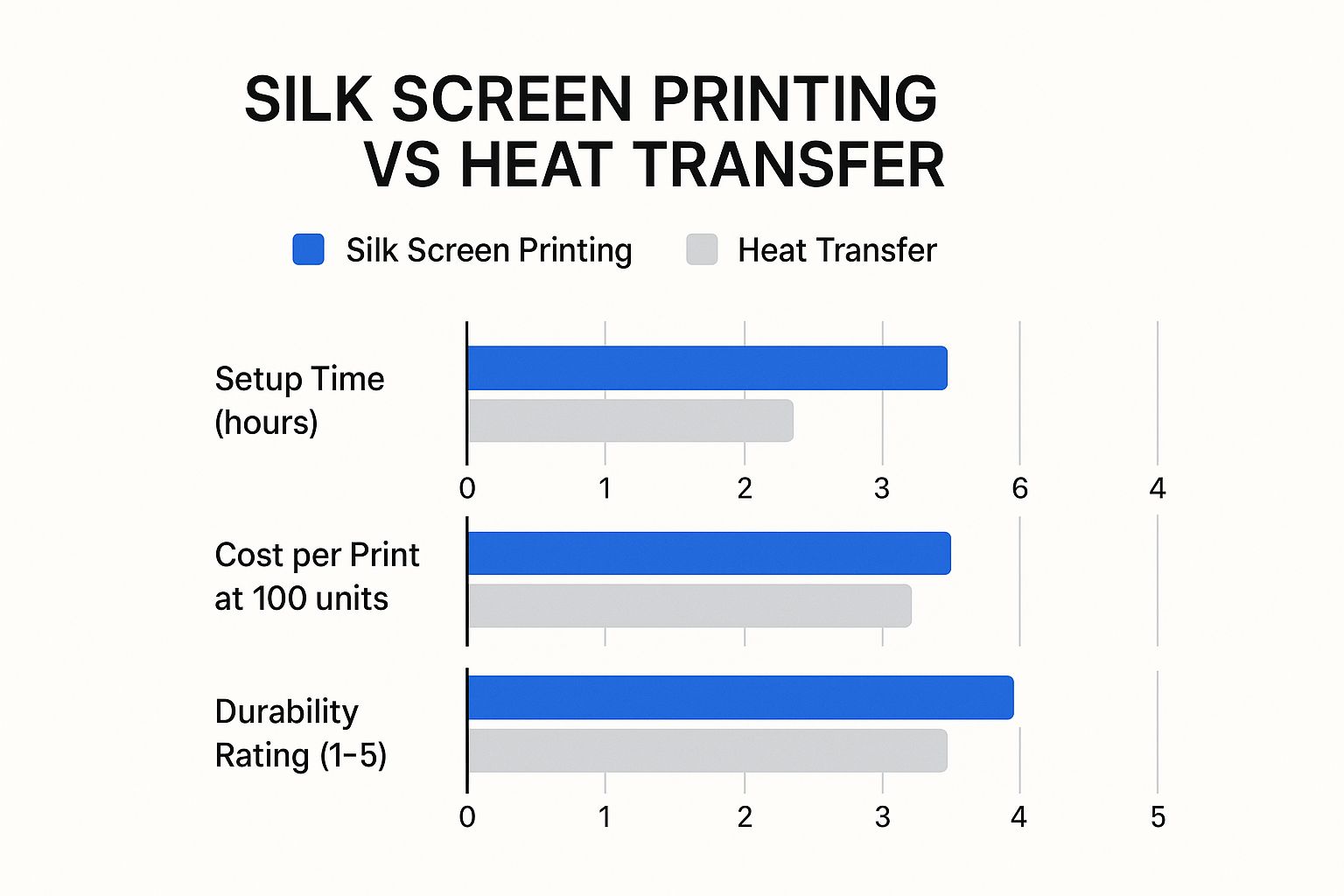

This visual guide quickly lays out the key trade-offs in setup, cost, and durability.

As you can see, heat transfer's nearly instant setup is a world away from screen printing's upfront effort. But on the flip side, screen printing wins hands-down on durability and brings down the per-item cost significantly on bigger jobs.

Key Factors for Your Decision

A few critical factors should guide your thinking here. The size of your order is probably the biggest one. Screen printing requires creating a separate stencil (or "screen") for every single color in your design. That initial setup is labor-intensive, which makes it impractical for a handful of shirts but incredibly efficient once you're printing in volume. Heat transfer, with almost no setup, is tailor-made for one-offs or small batches.

The complexity of your design is another major consideration. Heat transfer can reproduce photorealistic images, fine details, and smooth color gradients without breaking a sweat. Screen printing, however, is at its best with bold, graphic designs using a limited number of solid colors.

A key differentiator you can't see but can definitely feel is the texture. Screen printing ink soaks into the fabric, creating a soft finish that feels like it’s part of the garment. Heat transfers, on the other hand, press a design onto the surface, which can sometimes feel like a stiffer layer on top of the fabric.

While silk screen and heat transfer are the go-to methods for apparel, other options exist for different materials. For instance, offset printing is a fantastic choice for high-volume projects on paper, like flyers or business cards. But for fabric, the decision usually comes down to the head-to-head comparison below.

To make things even clearer, here’s a quick breakdown of how these two methods stack up against each other.

Silk Screen Printing vs Heat Transfer At a Glance

| Feature | Silk Screen Printing | Heat Transfer |

|---|---|---|

| Best For | Bulk orders (50+ items), simple logos, and corporate branding. | Small batches, custom one-offs, and photorealistic designs. |

| Durability | Extremely high. The ink becomes part of the fabric and lasts for years. | Moderate. The design sits on top and may crack or fade over time. |

| Design Complexity | Best for simple graphics with a limited number of spot colors. | Excellent for complex, multi-color images, gradients, and photos. |

| Fabric Feel | Soft and breathable, as the ink is absorbed into the fibers. | Can feel like a plastic layer on top of the shirt, less breathable. |

| Cost Structure | High initial setup cost, but a very low cost per item on large runs. | No setup cost, making it affordable for single items or small orders. |

Ultimately, this table helps distill the choice down to your specific needs—whether it's a large-scale branding project or a single custom-designed shirt.

How Silk Screen Printing Works

Silk screen printing, or serigraphy, is a time-tested technique that’s built a reputation for creating stunningly vibrant and tough-as-nails designs. It's a hands-on, meticulous process that has been perfected over centuries, making it the undisputed champion for high-volume jobs like band merch or company uniforms.

At its heart, screen printing works by pushing ink through a stenciled mesh screen directly onto a garment. The real trick is that each color in your design needs its own dedicated screen. This is why it shines with bold, graphic designs that have clean color breaks, rather than complex photographic images with subtle gradients.

The Stencil Creation Process

First things first: you have to make the screens. A printer starts by coating a fine mesh screen with a light-sensitive emulsion. After it dries, a film positive—which is just a transparent sheet with your design printed on it in solid black—is placed on the screen.

Next, the screen gets blasted with a powerful UV light. The light hardens the emulsion everywhere except where the black design blocks it. A quick rinse with water washes away the soft, unexposed emulsion, leaving a perfect stencil of your design right in the mesh.

You have to repeat this entire setup for every single color in the artwork. So, a three-color logo means prepping three different screens, all calibrated to align perfectly.

At its core, silk screen printing is a method of controlled ink application. The stencil ensures that ink only passes through to the fabric in the exact shape of your design, creating a clean and precise image every time.

Yes, this prep work takes time and skill, but it's what makes screen printing so efficient for big jobs. Once the screens are ready, a printer can churn out hundreds of identical items with incredible speed.

Applying Ink To Fabric

With the stencils prepped, the real fun begins. A t-shirt or other item is laid flat on a board called a platen. The first screen is lowered into position right on top of it.

The printer then pours a thick line of ink across the top of the screen and pulls it down firmly with a rubber blade known as a squeegee. This smooth, even pressure forces the ink through the open parts of the stencil and onto the fabric. If the design has more colors, the shirt rotates to the next station for a new screen and a new color.

Often, between each color layer, the ink is "flash-cured" with a quick blast of heat. This helps dry it just enough to prevent the fresh ink colors from smudging or bleeding into each other.

- Plastisol Inks: These are the workhorse of the industry. They're essentially a liquid plastic that sits on top of the fabric. They have to be heated to around 320°F (160°C) to cure properly, forming a tough, opaque layer that feels slightly raised.

- Water-Based Inks: These inks soak into the fabric's fibers, resulting in a much softer, almost non-existent feel. They're perfect for achieving a vintage look on light-colored cotton garments.

Curing And Durability

The final step is arguably the most important: curing. After the last color is applied, the garment travels down a conveyor belt through a massive dryer. This intense heat permanently bonds the ink to the fabric, creating a finish that's incredibly resistant to cracking, peeling, and fading.

This chemical reaction is the secret to screen printing’s legendary durability. The design essentially becomes part of the fabric, not just a layer sitting on it. This is why it’s the go-to method when you need a print that will last.

Because of the intensive setup involved in creating separate stencils, silk screen printing is most cost-effective for larger orders. In markets across the United States and Europe, it becomes the clear economic winner for jobs over 100 units, delivering durable prints that can handle more than 50 industrial wash cycles. You can explore more on the cost benefits of screen printing for bulk orders on gentlpk.com.

Understanding the Heat Transfer Process

Where screen printing is the king of big batches, heat transfer printing is the champion of versatility. It’s the modern answer for creating intricate, full-color designs without the headaches of a multi-screen setup. For small businesses, custom one-offs, or personalized gear, this method is a game-changer.

The concept is brilliantly simple. You create a design on a special transfer material, and then a heat press uses heat and pressure to permanently bond it to the garment. This opens the door to photorealistic images, smooth color gradients, and tiny details that are either a nightmare or just plain impossible with screen printing. If you’re just starting out or need to produce a handful of unique items, heat transfer is a low-cost, high-impact way to get into custom apparel.

Types of Heat Transfer Methods

It's important to know that "heat transfer" isn't a one-size-fits-all term. The right method really boils down to your design's complexity and the final look you're after. Picking the wrong one can completely change the outcome.

You'll mainly run into two types of transfers:

-

Heat Transfer Vinyl (HTV): This is your go-to for bold, simple graphics. A machine cuts your design out of a sheet of colored vinyl. After you "weed" away the extra material, you just place the design on the shirt and press it. Think sports jerseys with names and numbers or simple company logos—that's the sweet spot for HTV.

-

Digital Transfers: When you have a complex, multi-color design, this is where you turn. The artwork is digitally printed onto a special transfer paper or film, often using high-quality solvent inks. This technique handles unlimited colors, gradients, and even photographic detail, making it perfect for detailed logos or custom art. To dive deeper, check out our detailed guide on heat transfer shirt printing.

Here’s the key takeaway: HTV is a "subtractive" process where you cut a design from a solid color. A digital transfer is an "additive" process where you print the exact image. This one distinction is what determines which method will work for your artwork.

This adaptability is a huge deal in the silk screen printing vs. heat transfer debate. Screen printing forces you to simplify, while heat transfer lets you embrace complexity.

The Step-By-Step Heat Transfer Application

One of the best things about heat transfer is its straightforward, repeatable workflow. It’s far quicker than aligning multiple screens, which means you can turn around small and medium-sized orders in a flash.

Step 1: Create the Design Digitally

It all starts on the computer. Your artwork is created or loaded into design software, where you make sure it's sized correctly and ready for the next step.

Step 2: Prepare the Transfer Material

Depending on your method, the design is either printed onto transfer paper or cut from a sheet of heat transfer vinyl. Precision here is key—any mistakes at this stage will show up on the final product.

Step 3: Apply Heat and Pressure

This is where it all comes together. You carefully position the prepared transfer on the garment and place it in a heat press. The machine applies a precise combination of temperature (usually around 300-350°F), pressure, and time to fuse the design directly into the fabric's fibers.

After the timer goes off, you remove the garment and peel away the backing paper. What’s left is a crisp, vibrant design. You can go from a blank shirt to a finished product in minutes, a world away from the long setup times of screen printing. This speed and simplicity make it an incredibly powerful tool for any on-demand printing business.

Comparing Cost, Durability, And Print Quality

When you're trying to choose between silk screen printing and heat transfer, the decision really boils down to three things: how much it costs, how long it will last, and what the final print looks like. Each method shines in different situations. It's never about which one is flat-out "better," but which is the right tool for your specific job.

Let's get past the surface-level stuff and really dig into how these two stack up head-to-head. We'll look at the money behind each, the science of their longevity, and the unique visual feel they each produce. This will give you the clarity you need to put your money in the right place.

Cost and Durability Analysis

To make a smart financial choice, you need to see how the numbers play out at different volumes and how long the print will realistically last. The table below breaks down the cost-per-unit economics and expected durability for both methods.

| Metric | Silk Screen Printing | Heat Transfer |

|---|---|---|

| Setup Cost | High (screen creation) | Zero to Low |

| Cost at 10 Units | ~$20-25 per unit | ~$15-20 per unit |

| Cost at 100 Units | ~$5-8 per unit | ~$15-20 per unit |

| Expected Lifespan | 50+ washes | 25-30 washes |

As you can see, heat transfer is the clear winner for small, one-off jobs. But as soon as your order size grows, screen printing’s efficiency takes over, dramatically lowering the cost of each individual item and delivering a much longer-lasting product.

Analyzing the Cost Models

The financial side of things is often the biggest deciding factor in the silk screen printing vs heat transfer showdown. Screen printing is all about economies of scale—you have a high initial setup cost, but a very low cost for each item you print after that. This is because creating a separate, precise screen for every color in a design takes time and skill.

But once those screens are ready to go, you can print hundreds of shirts with incredible speed. This efficiency makes screen printing the undisputed champion for bulk orders. The more you print, the less each shirt costs you.

Heat transfer is the exact opposite. It has virtually zero setup cost. You can print a single, full-color design without any of the prep work screen printing requires. This makes it a fantastic option for small businesses, one-off custom orders, or just testing a new design idea without a huge financial commitment. The cost per shirt stays pretty much the same, whether you're making one or twenty.

Key Insight: The break-even point is everything. If you're ordering more than 50 pieces with the same design, screen printing almost always becomes the cheaper option. For any quantity below that, heat transfer's lack of setup fees gives it the financial advantage.

This fundamental economic difference really defines where each method fits best. A local band needing 200 tour shirts will save a ton with screen printing. Meanwhile, an Etsy seller making personalized birthday shirts on demand will thrive with the flexibility of heat transfer.

Durability and Longevity Under Pressure

How well a print holds up after being thrown in the wash dozens of times is a direct result of how it was applied. Durability isn't just a talking point; it's a promise to your customer about the quality they're paying for.

Screen printing creates a seriously durable bond. The ink is literally pushed through the screen mesh, forcing it to absorb directly into the fabric's fibers. Once it's properly cured with high heat, the ink forms a permanent bond with the material. The design isn't just sitting on top of the shirt—it becomes part of it.

The result is a print that can handle years of use without cracking, peeling, or fading away. It’s built to last, which is why it’s the go-to method for work uniforms, school spirit wear, and premium brand merchandise.

Heat transfer, on the other hand, applies the design as a thin layer on top of the fabric. Whether you're using vinyl (HTV) or a printed transfer sheet, the image is essentially glued to the surface using heat. Modern transfer materials are much better than they used to be, but they are still more vulnerable to wear and tear.

Over time, all that washing and stretching can cause a heat transfer to crack, fade, or peel. It just doesn't have that same deep-down bond with the fabric that a screen print does. That said, for promotional giveaways or fashion items not meant for rugged, daily wear, its durability is often perfectly fine. Newer methods like DTF (Direct-to-Film) are also closing this gap, offering impressive stretch and wash-resistance. To see how that works, you can learn more about https://cobradtf.com/blogs/guides/what-is-direct-to-film-printing and how it's changing the game.

Print Quality and Visual Appeal

Finally, let's talk about how they actually look. The "best" quality really depends on the style of your design.

Screen printing is known for its incredible color vibrancy. The inks are thick and opaque, which creates bold, punchy colors that really stand out, especially on dark garments. Since each color is laid down individually, they stay pure and bright. The downside is that this method is a poor choice for photos or designs with subtle color gradients, as every single shade would need its own expensive screen.

Its strengths are:

- Bold, vibrant spot colors

- Excellent opacity on dark fabrics

- A clean, professional look for logos and graphic text

Heat transfer is the master of complexity. Because the design is printed digitally first, it can reproduce millions of colors, fine details, and photorealistic images with amazing accuracy. If your artwork involves a photograph, a detailed illustration, or smooth gradients, heat transfer is really the only way to go.

The trade-off is that the colors can sometimes look a little less saturated than screen-printed inks, and the design sits on the fabric with a distinct feel. The finish can be anything from a smooth matte to a slight gloss, depending on the type of transfer material you use.

Of course, when you need to put a logo on something other than fabric, like metal or wood, you'll need to look at different methods entirely. For a deep dive into how permanent, high-end branding is achieved on harder materials, check out this excellent guide to flawless laser logo engraving. It helps put fabric printing in perspective within the wider world of custom branding.

Making the Right Call: Real-World Scenarios

Knowing the technical specs is one thing, but applying that to a real-world business decision is where the rubber meets the road. It’s not about which method is "better" in a vacuum; it’s about which one is the perfect fit for your specific project. Let's walk through a few common business scenarios to see how this plays out.

By looking at these examples, you can take the guesswork out of the equation. You'll see exactly how each method's strengths align with different needs, helping you make a choice that’s both smart and cost-effective.

Scenario One: The Startup Clothing Brand

Let's say you're launching a new apparel line. You want to drop 10-15 different designs to see what sticks, but you’re starting small, maybe 25 shirts for each design. Your artwork is the main event—full of intricate details, multiple colors, and even gradients.

In this case, heat transfer is your best friend. Screen printing would be a financial nightmare. Imagine the cost of creating separate screens for each of your 10+ designs, especially since many have multiple colors. That's a huge upfront investment before you've sold a single shirt.

- No Setup Costs: With heat transfer, you can print designs on demand without paying for a single screen.

- Design Freedom: It's built for the kind of complex, full-color artwork you're using to define your brand.

- Low-Risk Market Testing: You can produce small batches, see what sells, and avoid getting stuck with a mountain of inventory for a design that flopped.

Heat transfer gives a new startup the agility it needs to experiment, find its voice, and connect with an audience without breaking the bank.

Choosing the right print method at the startup stage is a critical business decision. Heat transfer minimizes financial risk while maximizing creative freedom, making it the ideal choice for brands testing new, complex designs in small quantities.

Scenario Two: The Established Construction Company

Now, picture a construction company with a crew of 300 employees. They need high-visibility safety vests with a simple, one-color company logo on the back. The number one priority is durability. These vests will get beat up on-site and thrown in the wash constantly.

For a job like this, silk screen printing is the only way to go. The core need is extreme longevity. The ink has to fuse with the fabric to withstand daily abrasion, sun exposure, and harsh washing cycles without a hint of fading or cracking. That’s exactly what screen printing delivers.

And with an order of 300, it’s also the most cost-effective option by a long shot. Yes, there's a small setup fee for the screen, but the price per vest will be far lower than it would be with heat transfer. The simple, single-color design is right in this method's wheelhouse.

Scenario Three: The Local Band's Tour Merch

A local band is about to go on tour and needs merch for the shows. The plan is 150 t-shirts with a two-color graphic on the front and tour dates on the back. They're on a tight budget, but they need the shirts to look professional and hold up so fans can wear them for years.

This scenario lands squarely in silk screen printing's sweet spot. An order of 150 units is well past the point where screen printing becomes more economical than heat transfer. A two-color design is also straightforward and efficient to set up.

More importantly, the durability of screen printing protects the band's brand. A cheap heat transfer might start cracking after a few months, which doesn't look good. A screen-printed shirt, on the other hand, will last, turning every fan into a walking billboard for years to come.

Scenario Four: The Etsy Shop for Personalized Gifts

Finally, think about an Etsy seller who makes personalized gifts. Their bread and butter is creating one-of-a-kind t-shirts with a customer's pet photo and name on them. Every order is unique, and the production run is always one.

Here, heat transfer is the only viable option. Their entire business is built on customization. It would be logistically and financially impossible to create a new set of screens for every single order. Heat transfer lets the seller print detailed, full-color photos quickly and affordably for single-item jobs, making their entire business model possible.

How to Make the Right Choice for Your Project

When you're staring down the silk screen vs. heat transfer decision, it really boils down to the specifics of your job. There’s no single "best" method, so let's walk through a few practical questions to figure out exactly what you need.

Think of this as a quick checklist to point you in the right direction. Answering these will make the right choice obvious.

Your Project Checklist

-

What's your total order quantity? If you're running more than 50 pieces with the same design, screen printing is almost always going to give you a better price per shirt. For small batches, one-offs, or just testing the waters with a new idea, heat transfer is your most budget-friendly option.

-

How complex is your artwork? Got a design with photorealistic details, smooth gradients, or a whole spectrum of colors? That’s a job for heat transfer. But if you’re working with a bold, graphic logo using one to three solid colors, screen printing will make it pop.

-

How important is durability? For uniforms, workwear, or any apparel that’s going to see a lot of action and heavy washing, screen printing is the undisputed champ. The ink literally becomes part of the fabric. For promotional giveaways or trendy fashion pieces that aren't meant to last forever, a heat transfer will hold up just fine.

It's all a balancing act. A big order of simple, tough work shirts screams screen printing. A single, custom t-shirt with a family photo for a birthday gift? That can only be done well with heat transfer.

Don't forget that the fabric itself plays a huge role. Inks and transfers behave very differently depending on the material you're printing on. For a deeper dive, check out our guide on the differences between cotton vs polyester to see what I mean.

In the end, neither method is better—they’re just different tools for different jobs. The best choice is the one that lines up with your budget, design, and durability needs, ensuring the final product looks exactly how you pictured it.

Your Top Questions, Answered

Even after breaking down the pros and cons, you probably still have a few questions floating around. Let's tackle some of the most common ones that come up when people are trying to decide between screen printing and heat transfer.

Which Method Feels Softer On The Shirt?

Hands down, screen printing usually wins the "soft-hand" test. This is especially true when you're using water-based inks. The ink soaks right into the fabric, becoming one with the garment instead of just sitting on top.

Heat transfers, particularly vinyl (HTV), tend to feel like a separate layer on the shirt. You can definitely feel the texture. That said, newer transfer technologies like Direct-to-Film (DTF) are a huge improvement, offering a finish that's much more flexible and softer to the touch than the old-school, plastic-y transfers.

Can You Print On Polyester With Both Methods?

Absolutely, but you need to know what you're doing with each. They both come with their own set of rules for polyester.

- Screen Printing: This gets a bit tricky. You need to use special "poly-blocking" inks. If you don't, the dye from the polyester fabric can "migrate" or bleed into the ink, muddying up your colors. It's a common headache for screen printers.

- Heat Transfer: This method is fantastic for polyester. Sublimation transfers, for example, actually dye the polyester fibers directly, resulting in a permanent design with zero feel. Standard HTV also bonds really well to poly fabrics.

For performance wear or anything that's 100% polyester, heat transfer is often the safer, more reliable bet. You get brilliant colors without worrying about the dye migration issues that can plague a screen printing job.

Is One Method Faster For A Small Order?

For a one-off shirt or a small batch, heat transfer is the clear winner on speed. There’s almost no setup. You can take a design from your computer to a finished shirt in a matter of minutes.

Screen printing is the complete opposite. The setup process is a beast—you have to create a separate screen for every single color in the design. It's incredibly inefficient for just a few items. Screen printing only starts to pay off in speed when you’re cranking out dozens, or even hundreds, of the same exact print.

At Cobra DTF, we're all about high-quality Direct-to-Film transfers that give you the best of both worlds—stunning, detailed prints with serious durability and a soft feel. Made 100% in the USA, our transfers ship the same day, so you can get your projects done faster. See what you can create at https://cobradtf.com.