Cotton vs Polyester A Complete Fabric Guide

Share

The debate between cotton and polyester really boils down to one simple thing: are you looking for everyday comfort or high-performance function? Cotton is a natural fiber, known for being soft and breathable, making it a go-to for casual wear. On the other hand, polyester is a synthetic powerhouse, valued for its incredible resilience and ability to wick away moisture.

Your best choice really depends on what the garment is for. A soft, comfy t-shirt has totally different needs than a jersey that has to stand up to a tough workout.

Cotton vs Polyester At a Glance

To really get a feel for which fabric to choose, it helps to put them side-by-side. Each one has its own strengths that make it perfect for specific jobs, whether it's for a relaxed weekend tee or a durable uniform.

Here's a quick breakdown of their core differences:

| Attribute | Cotton | Polyester |

|---|---|---|

| Feel & Comfort | Very soft, breathable, natural feel | Smooth, sometimes silky, less breathable |

| Moisture Handling | Absorbs moisture, slow to dry | Wicks moisture away, dries quickly |

| Durability | Strong but can wear out over time | Extremely durable, resists stretching & shrinking |

| Wrinkle Resistance | Prone to wrinkling | Highly wrinkle-resistant |

| Best For Printing | Excellent for soft-hand feel (DTF/DTG) | Produces vibrant, sharp colors (DTF/Sublimation) |

| Hypoallergenic | Yes, naturally hypoallergenic | Can irritate sensitive skin |

The Bottom Line: If you're after pure comfort and a natural feel for everyday clothes, cotton is your winner. But if you need something that lasts, wicks away sweat, and holds a super-vibrant print, you’ll want to go with polyester.

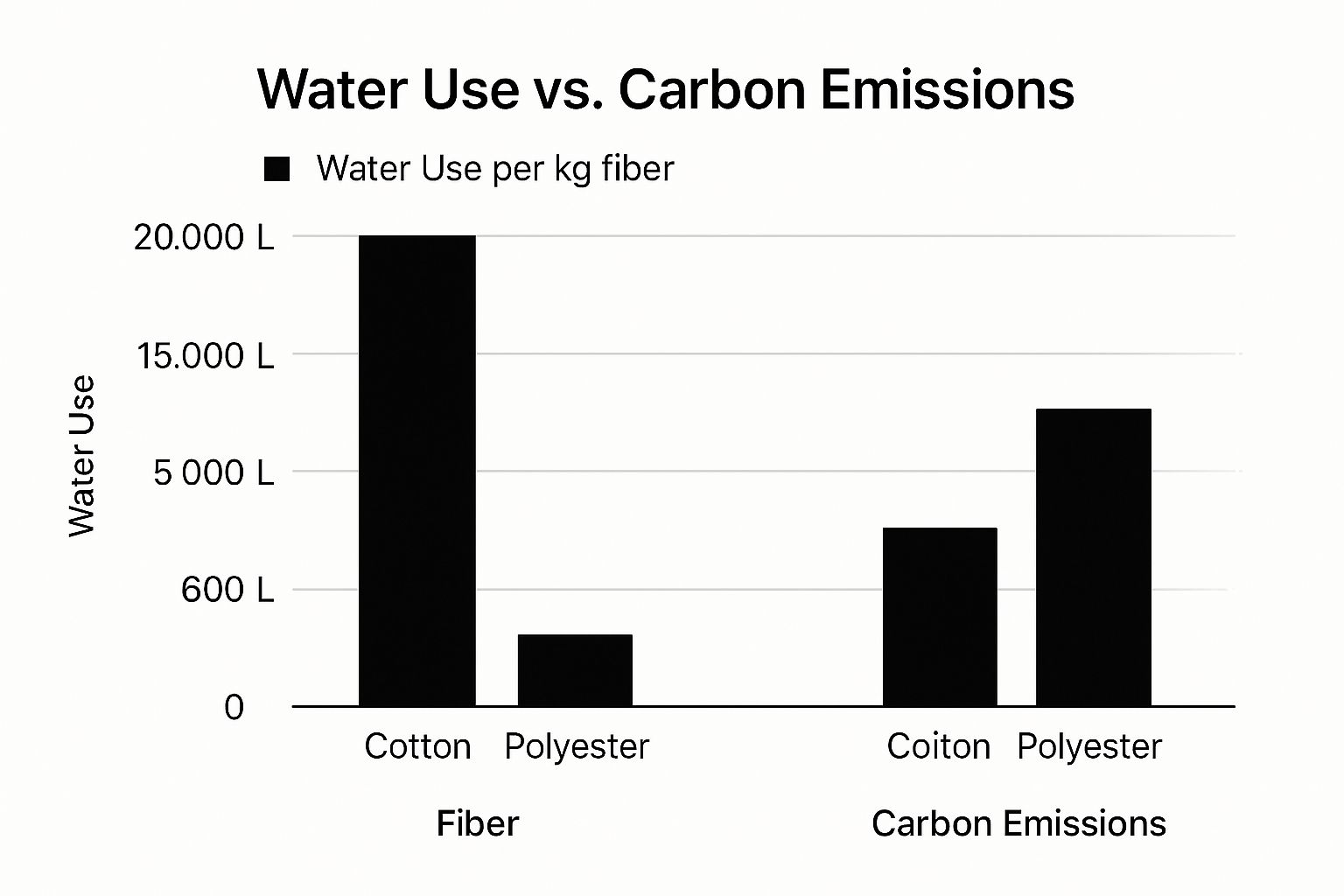

Beyond how they feel and perform, the environmental side of things adds another layer to the decision. Take a look at this.

The numbers make it pretty clear. Conventional cotton farming demands a massive amount of water, but polyester production carries a heavier carbon footprint for every kilogram made. It just goes to show there are complex trade-offs to consider when thinking about sustainability.

Understanding the Fibers: From Field and Lab

To really get to the bottom of the cotton vs. polyester debate, you have to go back to the very beginning. One comes from a field, the other from a lab. That single difference is the key to everything that follows—how they feel, how they perform, and even their impact on the environment. Their paths from raw material to a finished shirt couldn't be more different.

Cotton is a classic for a reason. It's a natural fiber that grows in the fluffy bolls surrounding the seeds of the cotton plant, a shrub we’ve been farming for thousands of years. The whole process is agricultural, tied to the seasons of planting and harvesting. This organic origin is exactly why we love cotton for its natural softness and breathability.

The Natural Path of Cotton

Cotton's journey starts in the field, where the bolls are picked by hand or machine. The raw fibers then head to a gin to be separated from the seeds. After that, they're carded to get all the fibers aligned, spun into yarn, and finally woven or knitted into that fabric we all know and love.

Its connection to the land makes cotton a major agricultural commodity. The global cotton market was valued at USD 41.78 billion and is still growing. China and India are the giants in this space, producing about 50.9% of the world's supply combined, with the United States not far behind. You can dive deeper into the cotton market's economic role and see detailed projections for its future.

The Engineered Creation of Polyester

Polyester, on the other hand, is a different beast entirely. It's 100% synthetic, a product of industrial chemistry involving petroleum, air, and water. There's no farming here—just a chemical reaction called polymerization that creates long chains of polyethylene terephthalate (PET). Yep, that's the same plastic used to make water bottles.

Those melted polymers are forced through a device called a spinneret, which works like a showerhead with tiny holes, to create long, continuous filaments. These filaments are then cooled, stretched, and either cut into shorter staple fibers or used as-is to make yarn.

Key Takeaway: Polyester's structure is engineered from the ground up. Cotton fibers are naturally irregular, but polyester filaments can be made perfectly smooth, crimped, thick, or thin. This allows manufacturers to build specific properties like durability, moisture-wicking, and wrinkle resistance right into the fabric itself.

This level of control is what gives polyester its incredible strength and versatility. While cotton's best qualities are a gift from nature, polyester’s are the result of precise scientific design. It's why polyester dominates in performance apparel where consistency and resilience are non-negotiable.

Fabric Performance: A Head-to-Head Comparison

Once you get past where they come from, the real cotton vs. polyester debate happens in how they act and feel in the real world. Choosing the right one is all about understanding how it breathes, how it handles sweat, and how it stands up to a beating. This is where you'll see the biggest differences, and it’s what will guide you to the right pick for a comfy t-shirt or high-performance athletic gear.

The first thing anyone notices is the feel. Cotton is famous for being incredibly soft, a quality that just gets better and better with every wash. Its natural fibers have a gentle texture that feels right at home against your skin, making it the undisputed king for everyday tees, loungewear, and bedsheets.

Polyester, on the other hand, usually feels smoother—sometimes even a bit slick or silky. Modern production has definitely made polyester softer than it used to be, but it still doesn't quite capture that plush, natural feel you get from a great cotton shirt.

Breathability and Moisture Management

How a fabric deals with air and sweat is a make-or-break factor. Cotton is wonderfully breathable, letting air move freely through the fibers. This is great for keeping you comfortable in mild weather, as it helps prevent that stuffy, sticky feeling. But this strength becomes a weakness when you start to sweat.

Cotton acts like a sponge, soaking up every drop of moisture. The fabric gets heavy, clings to your skin, and takes forever to dry. That's why it's a poor choice for any kind of intense workout.

Polyester is the complete opposite. It's not particularly breathable and can feel a bit warm, but its superpower is moisture-wicking.

- How it works: Instead of absorbing sweat, polyester's fibers are hydrophobic (water-hating). They pull moisture off your skin and push it to the outer surface of the fabric.

- The result: Sweat evaporates into the air almost immediately, keeping you dry and light. This is precisely why polyester dominates the world of activewear.

You could say cotton breathes, but polyester performs. For a lazy Sunday, cotton's airflow can't be beaten. For a 5K run, polyester's sweat-wicking is non-negotiable.

Durability After Repeated Washes

This is where polyester really flexes its muscles. Its synthetic polymer structure is incredibly strong and resilient. That means polyester garments can take a serious amount of abuse—they resist stretching, shrinking, and pilling far better than cotton. It also holds its color and shape remarkably well, wash after wash.

Cotton is a sturdy fiber, but it has its limits. With time and friction, its natural fibers will eventually break down. You’ll start to see thinning, fading, or even holes, especially in high-wear spots like collars and armpits. It's also far more prone to wrinkling than polyester.

For anything that needs to last through frequent, tough use—like work uniforms or sports jerseys—polyester is the clear winner for longevity. For those of us in the custom apparel game, this durability is key for the print as well. It’s particularly important when using modern methods; you can learn more about what Direct-to-Film printing is in our complete guide.

Hypoallergenic Properties

For anyone with sensitive skin, this isn't just about comfort—it's a health issue. Cotton is naturally hypoallergenic, which means it’s extremely unlikely to cause any irritation or allergic reaction. Its soft, chemical-free nature is gentle on the skin, making it the go-to for baby clothes and for people with conditions like eczema.

Polyester, being a synthetic plastic, can sometimes cause problems for a small number of people. While it isn't a common allergen, the fact that it doesn't breathe well can trap sweat and bacteria against the skin. This can sometimes lead to rashes or discomfort. If skin sensitivity is a top priority, cotton is almost always the safer choice.

How Each Fabric Handles Printing and Customization

When you're in the custom apparel game, the fabric you choose is everything. It's not just material; it's the canvas for your art. Whether you go with cotton or polyester will fundamentally change how your design looks, feels, and lasts, because these two fabrics couldn't be more different in how they handle ink and heat.

The choice isn't just about aesthetics, either. It's about aligning the fabric's natural properties with your printing method to get a professional-grade product that your clients will actually want to wear. Getting this right is what separates the amateurs from the pros.

Printing on 100% Cotton: The Natural Canvas

Cotton has been the go-to for a reason. Its natural, porous fibers act like a sponge, readily soaking up inks. This is a huge advantage for methods like Direct-to-Garment (DTG) printing, where water-based inks penetrate and stain the fibers directly. The result is that classic, soft hand-feel—the design feels like it's part of the shirt, not just sitting on top of it.

That absorbency does come with a small trade-off, though. As the ink soaks in, colors can sometimes look a bit muted or less crisp compared to how they'd appear on a synthetic fabric. For brands going for a vintage or washed-out vibe, this is actually a perfect match.

When it comes to Direct-to-Film (DTF) transfers, cotton is a fantastic surface. The heat-activated adhesive on the DTF film grabs onto the cotton fibers for a solid, lasting bond. This gives you a print that’s both vibrant and flexible, stretching and moving with the fabric. If you're weighing your options, understanding the nuances of DTF vs. DTG printing is a great place to start.

Printing on Polyester: Vibrant but Tricky

Polyester is a whole different beast. As a synthetic plastic, its fibers are non-absorbent. Ink doesn't soak in; it sits right on the surface. This is why printing methods like sublimation and DTF transfers create such incredibly sharp, eye-popping results on polyester. The colors are brilliant because there's no fiber absorption to dull them down.

But this is also where things get technical. The single biggest headache when printing on polyester is dye migration.

Dye migration is what happens when the heat from your press reactivates the dye in the polyester fabric itself. That color can then bleed through your transfer, turning a crisp white design into a muddy pink or gray mess.

Thankfully, there are ways to fight back. Experienced printers have a few tricks up their sleeves to prevent this:

- Use Low-Bleed or Blocker Transfers: These specialized DTF transfers have a built-in barrier layer specifically designed to stop the fabric's dye from bleeding into your design.

- Lower Your Press Temperature: Applying your transfer at the lowest effective temperature for the shortest possible time can prevent the fabric dyes from activating in the first place.

- Source Quality Garments: Stick to high-quality polyester from trusted manufacturers. Cheaper fabrics are often the worst offenders when it comes to dye migration.

In the end, polyester can give you unparalleled color vibrancy, but it requires more skill, patience, and the right supplies. Cotton, on the other hand, is far more forgiving and delivers a softer finish, making it a reliable workhorse for countless projects. The right choice really comes down to balancing the look you want with the technical demands of the fabric.

Evaluating Environmental and Sustainability Factors

When you're choosing between cotton and polyester, the environmental conversation isn't as simple as "natural vs. synthetic." Frankly, both materials have their own baggage, and making a responsible choice means understanding what you're trading off. Are you more concerned about water use, or what happens to the garment at the end of its life?

The Cotton Conundrum: Natural But Thirsty

Cotton's biggest selling point is that it's a natural fiber. It comes from a plant, it's renewable, and—most importantly—it's biodegradable. A 100% cotton shirt, once you’re done with it, can break down and return to the soil, which is a huge plus in our fight against textile waste.

But that's only part of the story. Conventional cotton farming has a massive environmental footprint. It's an incredibly thirsty crop, demanding huge amounts of water. On top of that, it often relies on a heavy cocktail of pesticides and chemical fertilizers that can wreck soil health and pollute nearby water systems.

The Synthetic Side of Sustainability

Polyester is on the complete opposite end of the spectrum. It’s made from petroleum, a non-renewable resource, and its manufacturing process is energy-intensive, adding to carbon emissions. The real kicker, though, is that polyester is not biodegradable. It sticks around for centuries in a landfill.

Worse yet, every time you wash a polyester garment, it sheds microplastics. These tiny plastic bits wash down the drain, find their way into our oceans, and create a massive problem for marine life. It’s a persistent issue that lasts the entire life of the garment.

A better path forward is emerging with recycled polyester (rPET). It's made by melting down old plastic bottles and spinning them into new fiber. This approach cuts our dependence on new oil, keeps plastic out of landfills, and uses far less energy than creating virgin polyester.

Polyester is the most used textile on the planet, accounting for about 57% of all fiber production, while cotton sits at around 20%. It’s a sobering statistic, and even with the rise of rPET, its adoption has slowed down recently. If you want to dive deeper into these numbers, the 2024 Materials Market Report is a great resource.

Ultimately, there's no perfect answer. The choice really comes down to your brand’s values. For those committed to sustainability, opting for organic cotton or using rPET for your DTF custom transfers are two of the best ways to reduce your environmental impact.

Making the Right Call for Your Project

So, cotton or polyester? The truth is, there's no single "best" fabric. The real question is about matching the material to its mission. Think about what you need the garment to do, and the right choice becomes much clearer. All the factors we've covered—from how it feels on the skin to how it holds up after a dozen washes—should guide your decision.

For pure, everyday comfort, cotton is still king. Nothing quite beats its natural softness and breathability. That makes it the obvious choice for casual tees, loungewear, or anything for someone with sensitive skin. If a gentle, natural feel is what you're after, you can't go wrong with 100% cotton.

When to Pick Cotton vs. When to Pick Poly

But when performance is the name of the game, polyester steps up. Its ability to pull sweat away from the body and stand up to serious abuse makes it the go-to for workout clothes, team jerseys, and outdoor gear. For anything that involves sweat, constant washing, or rough conditions, polyester’s engineered resilience is exactly what you need.

Then you have the blends, which try to give you the best of both worlds. A good cotton/poly blend combines the soft hand-feel of cotton with the durability and wrinkle-resistance of polyester. This makes them incredibly versatile for everything from corporate polos to everyday shirts that need to look sharp without a lot of fuss.

Key Insight: Stop thinking about which fabric is "better." Instead, ask yourself: What is the primary job of this garment? Is it all about comfort? Performance? Or a balance of both? Answering that one question will point you straight to the right material every time.

There’s a reason polyester is so dominant in performance apparel. The global market for polyester fiber was valued at USD 77.07 billion and is expected to hit USD 129.97 billion by 2032. That growth is fueled by its low cost and incredible versatility for demanding jobs. You can dig deeper into the numbers by checking out this report on the growth of the polyester fiber market.

Wrapping Up: Your Cotton vs. Polyester Questions Answered

To finish things off, let's go through a few of the most common questions I hear when people are weighing cotton against polyester. These quick answers should clear up any lingering doubts and help you make the right call for your project.

Is a 50/50 Cotton/Polyester Blend a Good Choice?

It's not just a good choice; it's often the perfect compromise. The 50/50 blend truly gives you the best of both worlds. You get the soft, natural feel of cotton combined with the resilience, wrinkle resistance, and moisture-wicking capabilities of polyester.

This versatility makes it a go-to fabric for a ton of applications:

- Everyday tees: They hold their shape and color far better than pure cotton after repeated washes.

- Company uniforms: They need to look sharp all day and stand up to daily wear, which is where the polyester component shines.

- DTF prints: The blend provides a great surface that balances the softness people love with the color pop that polyester delivers.

What's Better for Hot Weather?

This really depends on the type of heat you're dealing with.

If you're in a dry heat, 100% cotton is your best friend. Its natural breathability lets air flow right through, which feels fantastic. But the moment you start to sweat, that advantage disappears—cotton soaks up moisture like a sponge and gets heavy.

For hot and humid conditions where sweating is inevitable, polyester is hands-down the winner. It's built to wick moisture away from your skin so it can evaporate, keeping you much drier and more comfortable than a damp cotton shirt ever could.

The bottom line: Think about your activity. Just relaxing in the heat? Go with cotton. Working out or doing anything active? Polyester is the way to go.

How Should I Care for Cotton and Polyester?

Following the care label is always rule number one, but here are the general guidelines. For cotton, stick to cold or warm water and tumble dry on a low-to-medium setting to minimize shrinking.

Polyester, on the other hand, prefers cold water. Tumble dry it on low heat, as high temperatures can permanently damage the synthetic fibers over time.

Ready to see your designs come alive on the perfect fabric? Cobra DTF provides premium, USA-made DTF transfers that look incredible on cotton, polyester, and blends alike. Get vibrant, long-lasting prints with fast, reliable shipping by visiting Cobra DTF's website today.