Choosing T-Shirt Fabric Material for Perfect Prints

Share

Picking the right t-shirt for your project always comes down to the fabric. It's the foundation of everything. If you want a tee that's soft and breathes well, cotton is your go-to. For workout gear, polyester is the champ. And if you need a little of both, blends offer a fantastic middle ground.

This guide is designed to cut through the noise and give you a real feel for how these fabrics actually perform. We'll get into what makes each one tick, so you can stop guessing and start choosing with confidence.

Your Guide to Choosing the Right T-Shirt Fabric

We're going to break down how each material feels to the touch, how it holds up over time, and—most importantly for us—how well it works with Direct-to-Film (DTF) printing. Think of this as your field guide to fabrics. By the end, you'll know exactly what you need for any project.

The material of a t-shirt defines its entire character. It determines how comfortable it is, how long it lasts, and how good a printed design looks wash after wash. It’s what separates a wardrobe favorite from a shirt that just collects dust. Getting it right is a balancing act between feel, function, and of course, cost.

Why Fabric Selection Matters

If you're creating custom apparel, you have to know your fabrics. It doesn't matter if you're running a small business or just printing for fun—your choice of material directly affects how happy people are with the final product.

Here’s a quick rundown of why this is so critical:

- Print Quality: Inks and adhesives behave differently on various fibers. A smooth, tight-knit cotton is a dream canvas for a crisp DTF print, while polyester can be a bit trickier and needs the right approach.

- Wearer Comfort: You can't beat the breathable feel of cotton for an everyday shirt. But for a 5k run? You need the moisture-wicking power of polyester. No question.

- Garment Longevity: A solid fabric blend can handle the abuse of daily wear and repeated washing without shrinking, pilling, or fading. It protects the shirt and the awesome design you printed on it.

Once you get the hang of fabric selection, you're in the driver's seat. You’re not just picking a shirt; you're crafting the perfect experience for the person who will wear it, from the moment they put it on to how it holds up a year from now.

To get a broader perspective on materials, it can be helpful to read about the best fabrics for different garment types, which covers everything from natural fibers to synthetics. For now, though, we’re zeroing in on t-shirts to give you the practical knowledge you need for your printing projects.

A Deep Dive Into Natural Cotton Fibers

Let's start with the undisputed king of t-shirts: cotton. When you imagine your favorite, most comfortable tee, chances are it's made from this classic t-shirt fabric material. There's a good reason for that. Cotton is incredibly soft and breathable, acting almost like a natural ventilation system for your skin, which is why it's the go-to for everyday wear.

Its popularity isn't just a feeling; it's a global reality. Cotton dominates the apparel industry, especially in massive markets like the US, China, and India. The material's natural comfort and knack for absorbing moisture make it a perfect fit for all sorts of climates and styles.

But here's something you might not know: not all cotton is the same. The real difference between a cheap, scratchy tee and a premium, butter-soft one comes down to the length and smoothness of the cotton fibers themselves.

Understanding the Different Grades of Cotton

The journey from a cotton plant to a finished shirt involves processing that can totally transform its feel and lifespan. Knowing these differences is your secret weapon for picking the right blank for your project.

Let's break down the common types you'll see on tags:

- Standard Cotton: Think of this as your entry-level, basic cotton. The fibers are shorter, which can make the fabric feel a bit rough. It’s budget-friendly and gets the job done.

- Ringspun Cotton: This is a nice step up. The cotton is spun in a way that twists and thins the fibers, making them longer and stronger. The difference is immediate—a ringspun shirt feels noticeably softer and holds up better over time.

- Combed and Ringspun Cotton: Now we're getting into premium territory. After the ringspun process, the cotton is literally combed to pull out any short, scratchy fibers and impurities. This leaves you with an exceptionally smooth, clean surface that is absolutely ideal for DTF printing.

- Pima or Supima Cotton: This is the top shelf. Pima and Supima cottons are known for their extra-long staple (EKS) fibers. This results in a fabric that's incredibly soft, strong, and has a subtle sheen. It’s also great at resisting pilling, fading, and stretching.

The main takeaway is simple: longer, smoother fibers result in a softer, stronger, and more premium-feeling t-shirt. This is exactly why a Combed and Ringspun tee feels lightyears ahead of a standard one.

The Good and the Bad of Cotton Fabric

Like anything, cotton has its strengths and weaknesses. It's naturally hypoallergenic, which makes it a great, safe choice for anyone with sensitive skin. Its absorbent properties also mean it's good at wicking moisture away from your body during light activity. For a more detailed breakdown, check out our guide on the specifics of cotton vs. polyester.

On the other hand, that same absorbency can be a drawback. Once cotton gets really saturated with sweat, it becomes heavy and takes a long time to dry out. It's also famous for wrinkling easily and can shrink in the wash if you're not careful.

Even with those quirks, its incredible comfort and fantastic printability keep it firmly at the top of the list for most t-shirt projects.

Understanding Performance with Synthetic Fabrics

While cotton reigns supreme for everyday comfort, synthetic fabrics are engineered for action. When you need a shirt that can handle a tough workout, a long hike, or just a sweltering summer day, materials like polyester are the clear winners.

Think of it this way: cotton is like a sponge, soaking up moisture and holding onto it. Polyester, on the other hand, is built to be hydrophobic—it naturally repels water. Instead of getting bogged down with sweat, its fibers pull moisture away from your skin and push it to the surface to evaporate. This "moisture-wicking" magic is what keeps you feeling dry and comfortable when the heat is on.

The Power of Polyester

Polyester isn't just about moisture management; it's a true workhorse. As a synthetic polymer, its fibers are incredibly strong and resilient, sidestepping many of the issues that affect natural materials.

That engineered toughness brings a few major advantages to the table:

- Exceptional Durability: Polyester can take a beating. It resists stretching, shrinking, and general wear and tear far better than most natural fibers, meaning your gear holds its shape through countless washes.

- Wrinkle Resistance: The structure of polyester fibers makes them naturally resistant to creasing. You can pull a poly tee out of a crammed gym bag, and it'll still look good to go.

- Superior Color Retention: Dyes lock into polyester fibers and stay put. This means vibrant, saturated colors that won't fade easily, which is a huge plus for eye-catching DTF prints.

Synthetic fabrics like polyester are purpose-built. They are designed from the ground up to solve specific problems—like managing sweat and surviving rough use—making them the default choice for performance apparel.

Navigating the Trade-Offs

Of course, no fabric is perfect. That same moisture-repelling quality that makes polyester a performance star also means it's not as breathable as cotton. In casual, low-intensity situations, it can sometimes feel a bit clammy if you're not generating enough heat to push moisture out.

Another thing to keep in mind is odor retention. The synthetic fibers can sometimes be a breeding ground for odor-causing bacteria, which means your workout gear might need a little extra attention on laundry day. Knowing these traits is crucial when picking the right t-shirt fabric material. If your main goals are athletic performance, durability, and bold, lasting color, polyester is an unbeatable choice that delivers every time.

Getting the Best of Both Worlds With Fabric Blends

Why pick one fabric when you can get the advantages of several all rolled into one? That's the whole idea behind fabric blends. They’re specifically created to mix the best qualities of different fibers, giving you a shirt that hits that sweet spot between comfort, durability, and performance.

Think of blends as the perfect middle ground. You get the soft, natural feel of cotton combined with the tough, engineered resilience you find in synthetics like polyester.

The most common blend you'll run into is the classic cotton-polyester mix. It’s a true team effort: cotton brings the softness and breathability, while polyester adds strength, fights off wrinkles, and helps the color stay bright. This results in a shirt that’s comfortable enough for all-day wear but tough enough to survive countless washes without stretching out or fading.

This winning combination makes these blends incredibly versatile. They’re just as good for a casual weekend shirt as they are for staff uniforms that need to stay looking professional from morning to night.

The Rise of the Tri-Blend

Want to take that blended-fabric concept to the next level? Meet the tri-blend. Often seen as the top-tier option, tri-blends mix three different fibers—usually cotton, polyester, and rayon. Rayon is the secret ingredient here; it’s a fiber made from wood pulp that gives fabric an incredibly soft, almost silky texture and a really nice drape.

Adding rayon into the mix creates a t-shirt that's not just durable but feels genuinely luxurious. Tri-blends are lightweight, exceptionally soft, and hang just right, which is why you see them used so often by fashion-focused brands. Their premium feel also makes them an amazing canvas for custom prints. If you're curious about how these materials perform with different printing methods, our guide on DTF custom transfers dives into the specifics.

A blend isn't just a random mix of fibers. It's a calculated recipe. By adjusting the percentages of cotton, polyester, and rayon, manufacturers can dial in the exact feel, function, and price they're aiming for.

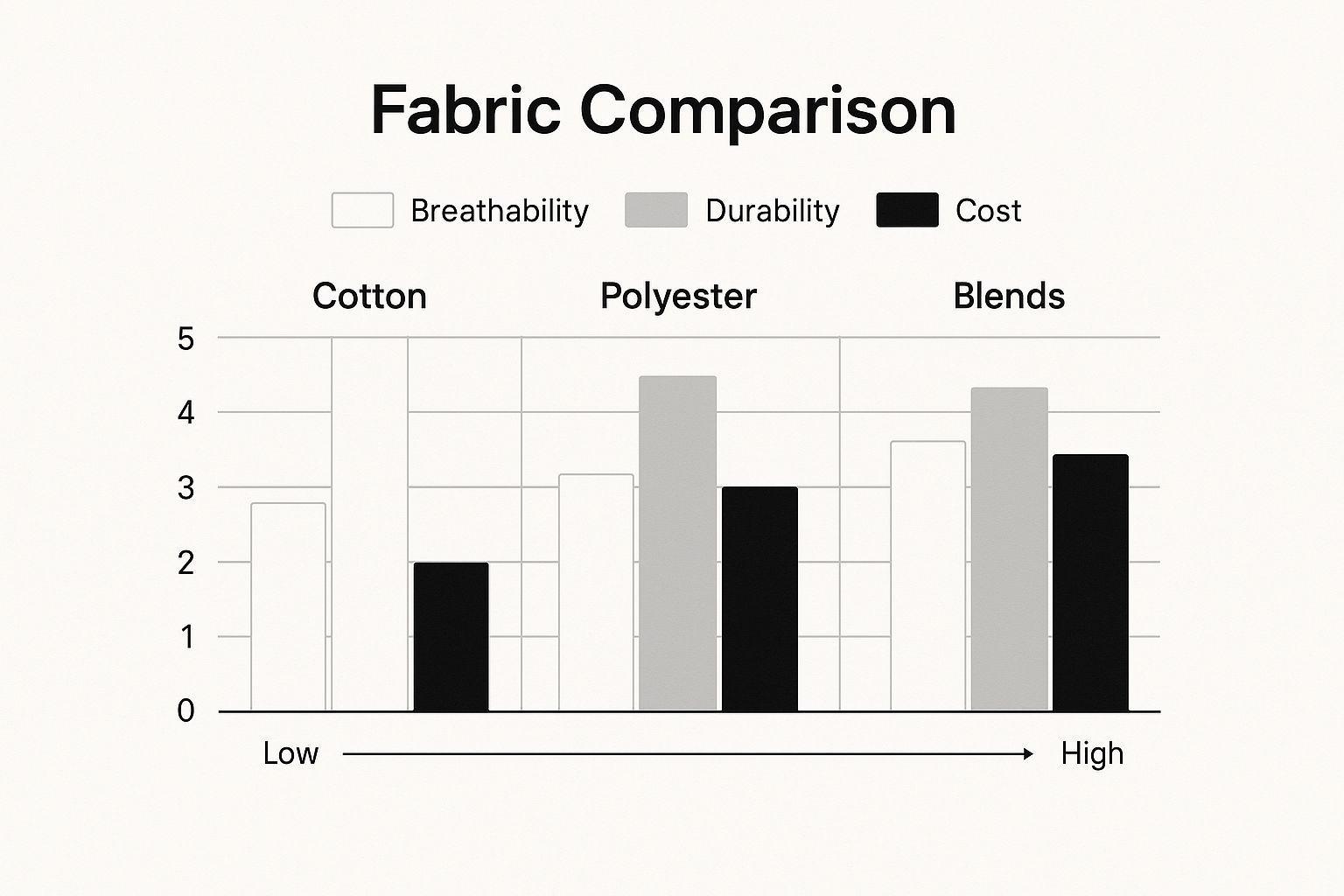

To help you visualize how these materials stack up, we've put together a simple comparison.

T-Shirt Fabric Material Comparison

Here's a quick look at how the four main t-shirt fabric options compare across the board, from comfort to their suitability for DTF printing.

| Fabric Material | Feel & Comfort | Durability & Care | Best For Printing (DTF) | Cost |

|---|---|---|---|---|

| 100% Cotton | Very soft, breathable, classic feel. | Moderate durability; prone to shrinking and wrinkling. | Excellent, especially for vibrant colors. | Low to Mid |

| 100% Polyester | Smooth, light, moisture-wicking; less breathable. | Highly durable, wrinkle-resistant, easy care. | Very good, but requires lower heat settings. | Mid |

| Cotton/Poly Blend | Soft yet durable, holds shape well. | Very durable, resists shrinking and wrinkles. | Excellent, offers a great balance. | Mid |

| Tri-Blend | Exceptionally soft, lightweight, with a nice drape. | Good durability, but can be more delicate. | Fantastic, creates a premium vintage look. | High |

This table makes it clear why blends are such a popular choice—they offer a fantastic all-around package that delivers on multiple fronts without breaking the bank.

As you can see, blends really do strike that perfect balance. They provide solid breathability and great durability, all at a mid-range price point, proving their worth as a go-to performer for almost any project.

How Your T-Shirt Fabric Choice Affects Print Quality

Let’s be honest, the success of any print job starts and ends with the t-shirt fabric material. Think of it like this: you wouldn't paint a masterpiece on a crumpled, low-quality canvas, right? The same logic applies here. Getting a handle on your fabrics is what separates amateur prints from professional work, especially when you're using Direct-to-Film (DTF) transfers.

Different fibers react to DTF transfers in their own unique ways. It's not just about how the shirt feels in your hand; it’s about understanding how that specific texture will bond with the ink and adhesive to create a print that looks amazing and actually lasts.

The demand for great-looking custom apparel is pushing the whole textile industry forward. The global fabrics market is expected to jump from USD 152.69 billion in 2025 to USD 203.41 billion by 2029, and a big part of that is thanks to digital printing methods like DTF. This isn't just a random statistic; it shows how vital it is to get the fabric-to-print relationship right. If you're interested in the nitty-gritty, you can dig into the full report on the fabrics market for more details.

Printing on Different Fabric Types

So, how do the most common fabrics actually behave when you press a DTF transfer onto them? Each material has its own personality, and knowing what to expect is half the battle.

-

100% Cotton: This is the gold standard for a reason. Cotton fibers are thirsty for ink, which means you get incredibly vibrant, deep colors. The print also has that soft, flexible feel that everyone loves. The natural weave of the cotton creates a perfect surface for the DTF adhesive to grab onto.

-

100% Polyester: If you're chasing after super sharp, almost photo-realistic images, polyester can be your best friend. The trade-off? It's sensitive to heat. You absolutely have to use lower temperatures on your heat press to avoid scorching the fabric or, even worse, melting it.

-

Blends (Cotton/Poly): These are the jack-of-all-trades and a fantastic middle ground. You get the soft, absorbent quality of cotton mixed with the strength and color-popping nature of polyester. Blends are often very forgiving and a reliable choice for a huge range of projects.

Actionable Tips for Perfect Prints

Knowing the theory is great, but putting it into practice is what really counts. Regardless of the fabric you’re working with, a couple of simple steps will make a world of difference in your final print quality. First up: always pre-press.

Pre-pressing your shirt for 5-10 seconds is probably the most important thing you can do for a good print. It gets rid of any hidden moisture and smooths out wrinkles, giving your transfer a perfectly flat, dry canvas to stick to.

Getting your heat press settings just right is equally important. Start with the recommended time and temperature for your specific DTF transfer and the fabric you're using. But don't be afraid to do a quick test on a scrap piece of fabric first! A small test can help you tweak your settings perfectly and save you from ruining a whole batch of shirts. Once you nail these simple techniques, you'll be able to produce top-notch, professional results on any t-shirt fabric material you choose.

Getting a Feel for Fabric Weight and Weave

So, we've covered the actual fibers that make up a t-shirt, but two other details are just as important in figuring out how a shirt will feel and perform: its weight and its weave. Getting a handle on these is like learning the secret language of apparel. It lets you pick the perfect blank every single time.

First up is fabric weight. You'll often see this measured in GSM, which stands for Grams per Square Meter. Just think of GSM as the fabric's density. A higher number means you're holding a heavier, thicker shirt, while a lower number points to something much lighter and softer to the touch. This one number tells you a ton about what the shirt was designed for.

Breaking Down Fabric Density

The real difference between a breezy summer tee and a rugged work shirt often just boils down to its GSM. Once you know the ranges, you can match the shirt to the project perfectly.

- Lightweight (Under 150 GSM): These are your airy, super-breathable shirts with a soft, flowy drape. They’re fantastic for hot weather or for brands going for that high-fashion, relaxed vibe.

- Midweight (150-200 GSM): This is the sweet spot and the most common range for a standard t-shirt. It strikes the perfect balance between being tough enough for daily wear but still comfortable, making it a go-to for most merchandise and everyday apparel.

- Heavyweight (Over 200 GSM): These are the workhorses. They're built for durability with a thick, structured feel that can take a beating. Think streetwear, workwear, or anything meant for cooler weather.

The Go-To T-Shirt Weave

Next, let's talk about the weave. When it comes to t-shirts, you’re almost always dealing with a jersey knit. It's a specific knitting style that results in a fabric with fine vertical ribs on the front and horizontal loops on the back. That's what gives a tee its signature softness and just the right amount of natural stretch for a comfortable fit.

The impact of fabric type and weave is huge, shaping a global shirt fabric market valued at around USD 46.39 billion in 2025. The entire industry is often categorized by these very factors. You can discover more about the shirt fabric market to see just how much these details drive its growth.

By understanding both weight (GSM) and weave (jersey knit), you can look at a product description and know exactly how that shirt will feel, drape, and perform before you even touch it.

This kind of knowledge is incredibly helpful when you're working with different printing methods. For instance, a smooth midweight jersey knit creates an ideal canvas for transfers, which is similar to the kind of stable surface you'd want when learning how to use heat transfer paper for your own custom designs.

Got Questions? We've Got Answers

Even after you've got the basics down, a few practical questions always seem to pop up when it's time to actually choose a shirt. Nailing these details is what separates a good project from a great one, whether you're printing a single shirt for yourself or a whole batch for a new business.

Let's dive into some of the questions we hear all the time.

What's the Best Fabric If I'm Trying to Be Eco-Friendly?

When it comes to sustainability, organic cotton is a champ. It's grown without all the synthetic pesticides and fertilizers that conventional cotton uses, which is a big win for the environment. Recycled polyester is another fantastic option, as it literally turns old plastic bottles into fresh fabric.

You might also come across Tencel™ Lyocell. This material is pretty cool—it’s made from wood pulp, but the manufacturing process recycles almost all the water and solvents used. If you're serious about sustainability, keep an eye out for official certifications like GOTS (Global Organic Textile Standard) on the tag. That's your proof that it meets strict environmental and social criteria.

How Do I Stop My Cotton Shirts From Shrinking?

Ah, the age-old enemy: shrinkage. Your best defense is a good laundry routine. Wash your cotton tees in cold water and tumble dry them on the lowest heat setting. Better yet, let them air dry.

Lots of shirt manufacturers now offer "pre-shrunk" cotton. This just means they've already put the fabric through a wash cycle to get most of the shrinking out of the way before it even gets to you. It's a great feature to look for, but always—always—check the care label inside the shirt for the final word.

I'm Starting a T-Shirt Business. Which Fabric Should I Use?

Starting a brand can be overwhelming, so you want a fabric that's easy to work with. For that, you can't go wrong with a classic 50/50 cotton-polyester blend. It's the perfect middle ground—you get the soft, natural feel of cotton, plus the strength and wrinkle-resistance of polyester.

This blend is also incredibly forgiving for all sorts of printing methods, especially DTF. It’s usually easier on the wallet than 100% premium cottons or fancy tri-blends, making it the ideal starting point to perfect your craft without breaking the bank.

Ready to create stunning, professional-quality prints on any t-shirt fabric? At Cobra DTF, we provide top-tier, American-made DTF transfers that deliver vibrant colors and incredible durability. Explore our premium DTF transfers and elevate your apparel today!