Sublimation Vs Heat Transfer A Complete Guide for Creatives

Share

The core difference between sublimation and heat transfer really boils down to one simple concept: sublimation embeds dye directly into the fibers of a material, while heat transfer lays a design on top. That’s it. But this single distinction changes everything—from the final feel and durability of the print to what you can actually print on, how much it costs to start, and what your daily workflow will look like.

Choosing the Right Printing Technology for Your Business

If you're launching a custom apparel shop or looking to scale an existing one, picking your printing method is one of the most important decisions you'll make. It’s not just about buying a printer; it’s about making a strategic investment that matches the products you want to sell, the customers you want to reach, and your overall business goals. Get this right from the start, and you're setting yourself up for success.

For anyone running a print-on-demand business, this choice is even more critical because it defines your entire product catalog. Knowing your tech inside and out also helps you market your items effectively, a key topic covered in this guide on Print On Demand Products on Shopify.

Key Factors to Consider

Before we get into the nitty-gritty, let's zoom out. Your choice will hinge on a few fundamental questions about your business model. Think about these carefully:

- What are you making? Are you focused on 100% polyester athletic gear, classic cotton tees, or hard goods like mugs and phone cases?

- What do your designs look like? Do you work with complex, full-color photos or simple text and blocky graphics?

- How many are you making? Is your business built on one-off custom gifts, or are you running large batches for local sports teams?

- What’s your startup budget? How much are you prepared to invest in a printer, heat press, and all the necessary supplies?

Answering these will point you in the right direction. While both methods can produce beautiful, professional products, they excel in very different arenas. If you need more guidance, we have a complete guide on finding the best t-shirt printing method for your needs.

At-a-Glance Comparison

To kick things off, here’s a quick-and-dirty breakdown of how these two technologies stack up.

| Feature | Sublimation | Heat Transfer (General) |

|---|---|---|

| How It Works | Dye turns to gas and infuses into the material | A printed layer is pressed onto the surface |

| Best For | 100% polyester & polymer-coated hard goods | Cotton, poly/cotton blends, various materials |

| Feel of Print | Zero feel; it's part of the fabric | You can feel a distinct layer on the surface |

| Color Limitations | Only works on white or very light-colored items | Works on any color fabric, including black |

| Durability | Permanent. It will not crack, peel, or fade. | Varies by type, but can crack or fade over time |

Understanding the Core Printing Processes

To really get a handle on the sublimation vs. heat transfer debate, you have to look at the science behind each one. They both end up in a heat press, sure, but what's happening on a molecular level is worlds apart. One is a chemical reaction, the other is more like a high-tech application.

This fundamental difference is what makes them suitable for completely different products and business models. Once you grasp these concepts, you'll be well on your way to picking the right tech for your shop.

The Science of Sublimation

Sublimation is a pretty cool process. It's when a solid turns directly into a gas, completely skipping the liquid stage. In our world, that means we take solid dye on a special sheet of paper, heat it up, and watch it vaporize. That gas then works its way into the open pores of polyester fibers or a polymer coating.

As everything cools down, the gas turns back into a solid—but now it’s permanently trapped inside the material. This gives you a print with absolutely zero feel or "hand." You can't feel it at all because it’s not sitting on top; it's part of the fabric.

Key Takeaway: Sublimation isn't printing on a shirt; it's dyeing the very fibers of the shirt. This is why the print is permanent and can never crack, peel, or fade, making it perfect for performance apparel that gets a lot of wear and tear.

The business side of this is huge. The global dye-sublimation market hit around $15.0 billion in 2024 and is expected to keep climbing. That growth is coming from the demand for durable, vibrant prints on textiles and personalized gifts. You can find more details on the growth of the dye-sublimation market in recent reports.

Heat Transfer: The Layered Approach

Heat transfer is a much broader category that works on a simpler idea: adhesion. Instead of becoming part of the fabric, a heat transfer design is a layer of material that gets pressed onto the surface with heat and pressure.

Think of it like an incredibly advanced, durable sticker. This umbrella covers a few different methods:

- Heat Transfer Vinyl (HTV): You cut your designs from colored vinyl sheets and press them onto the garment. This is your go-to for simple, bold graphics like team names and numbers.

- Direct-to-Film (DTF): A more modern approach where you print a design onto a special film, coat it with an adhesive powder, and then press the whole thing onto the fabric. DTF gives you the full-color detail of sublimation but works on almost any fabric.

Because these methods add a layer on top, they’re compatible with a massive range of materials, including 100% cotton, polyester blends, and dark fabrics—all no-go zones for sublimation. The trade-off is that you can feel this layer, and over time, it can be prone to cracking or fading after many washes. For more on the material limits of sublimation, check out our guide on what is sublimation printing.

A Detailed Comparison of Performance and Quality

When you're deciding between sublimation and heat transfer, you're looking at two fundamentally different ways to get a design onto a product. This choice trickles down to affect everything—from the feel and durability of your final product to the very fabric of your business operations. It’s not just about aesthetics; it's about matching the right process to your specific goals.

Let's break it down, piece by piece, so you can see where each method truly shines.

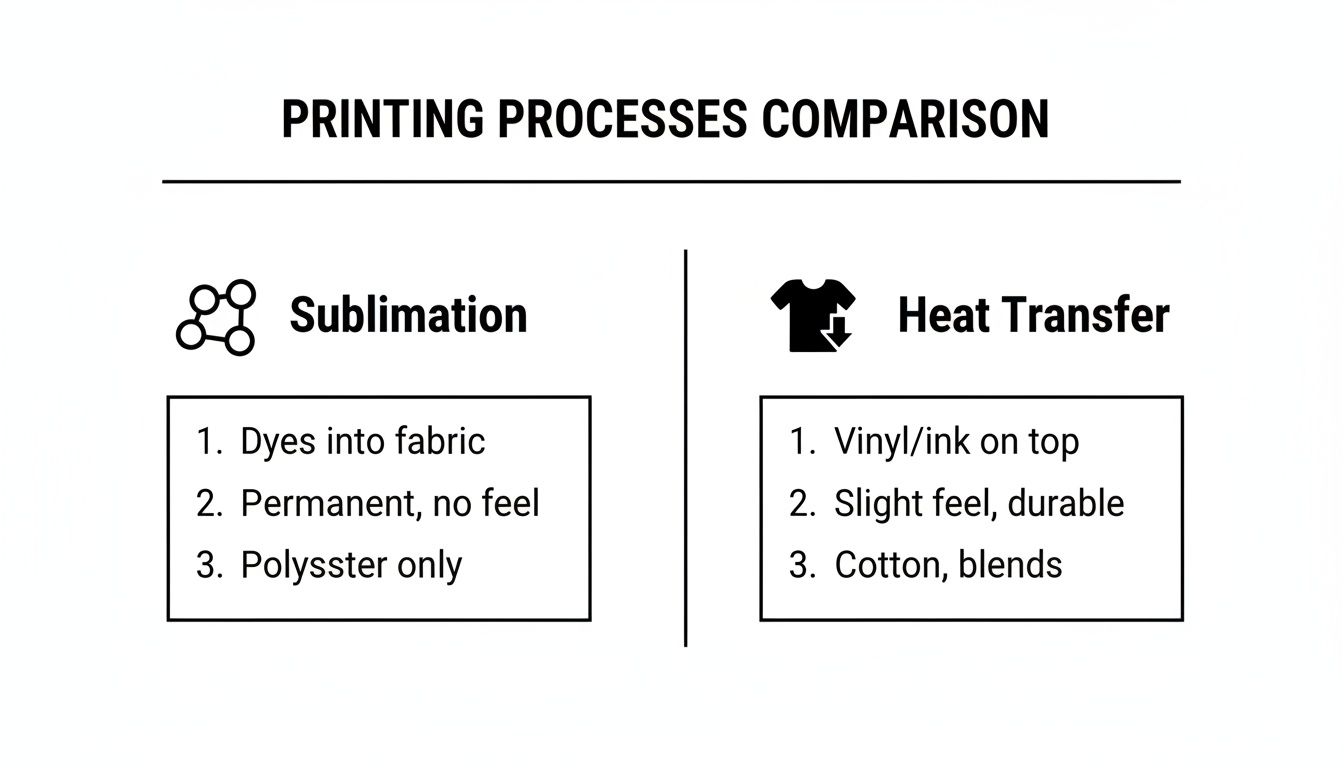

First, here's a quick visual that gets right to the heart of how these two processes work.

As you can see, sublimation becomes one with the polyester fibers. Heat transfer, in contrast, sits on top of the material. This single difference is the key to understanding all their strengths and weaknesses.

Sublimation vs Heat Transfer At a Glance

To make sense of the key trade-offs, it helps to see the big players side-by-side. This table gives you a quick snapshot of how sublimation stacks up against the two most popular heat transfer methods: Heat Transfer Vinyl (HTV) and Direct-to-Film (DTF).

| Attribute | Sublimation | Heat Transfer Vinyl (HTV) | Direct-to-Film (DTF) |

|---|---|---|---|

| Material | Polyester & polymer-coated items only | Cotton, poly, blends, canvas, leather | Cotton, poly, blends, denim, and more |

| Fabric Color | White or light-colored fabrics only | Any color, including darks | Any color, including darks |

| Feel/Hand | Zero feel; dye is infused in the fabric | Has a tangible feel, can be thick | Soft, flexible, and lightweight feel |

| Durability | Permanent; will not crack, peel, or fade | Good, but can crack/peel over time | Excellent; flexible and long-lasting |

| Color Detail | Photographic quality, unlimited colors | Best for solid colors and simple designs | Photographic quality, unlimited colors |

| Startup Cost | Moderate to High (Printer, ink, press) | Low (Cutter, press, vinyl) | High (Printer, shaker/dryer, press) |

While this table offers a great starting point, the real decision comes down to the nuances of your specific business needs.

Material Compatibility and Limitations

The most rigid dividing line between these technologies is what you can print on. This isn't a small detail—it's a hard limit set by chemistry.

Sublimation works through a slick chemical process where solid dye turns into a gas under heat, bonding directly with polymer fibers. This means sublimation is strictly for 100% polyester fabrics or specially-coated hard goods. It simply will not work on natural fibers like 100% cotton because there are no polymer molecules for the gaseous dye to grab onto. Sure, you can press on a poly-cotton blend, but the colors will look muted and faded, giving you a "vintage" effect whether you want one or not.

Heat transfer methods are the polar opposite—they're incredibly versatile. Since they work by applying a layer of material on top of the fabric with an adhesive, you can press them onto almost anything.

- Cotton: The undisputed king of casual apparel and the primary playground for Heat Transfer Vinyl (HTV) and Direct-to-Film (DTF).

- Polyester & Blends: Both HTV and DTF work beautifully here, giving you an alternative to sublimation for performance wear.

- Canvas, Denim, and Leather: There are specialized heat transfer materials designed specifically for these tougher, non-traditional substrates.

Critical Differentiator: If your business is built on selling custom designs for classic cotton t-shirts, heat transfer isn't just an option—it's your only option. Sublimation is a non-starter for the 100% cotton market.

Durability and Feel

How a print feels in the hand and how it survives the washing machine are massive factors for customer happiness. This is where the whole "infused vs. layered" concept really comes into play.

A sublimated print is completely permanent. Because the dye is literally part of the fabric, the design will last as long as the garment itself. It will never crack, peel, or fade, making it the hands-down winner for items that take a beating, like sports jerseys or activewear.

Better yet, a sublimated print has zero "hand"—you can't feel it at all. Run your hand across the surface, and it just feels like fabric. This preserves the garment's original breathability and comfort, which is a huge deal for performance apparel.

Heat transfer prints have a different story. As a surface-level layer, their durability can vary wildly based on the type (HTV, screen printed transfers, DTF) and the quality of the materials. While premium transfers hold up very well, they are not invincible and can eventually show their age.

With any heat transfer, there's always a tangible feel to the print. This can range from a thin, soft layer with modern DTF transfers to a thicker, almost plastic-like feel with some specialty vinyls. This added layer can also affect the fabric's breathability, a key consideration for athletic or performance-focused products.

Color Vibrancy and Detail

Both methods can produce gorgeous, eye-popping prints, but they really excel at different kinds of artwork.

Sublimation is famous for its ability to create photographic-quality detail with an unlimited color palette and perfectly smooth gradients. The colors are incredibly bright and vivid, especially on a white polyester base. But there's a catch: sublimation ink is transparent.

This means sublimation has no white ink. You can’t print on dark fabrics because the color of the shirt will show through your design. Any white areas in your artwork will simply be the color of the garment itself. For the best results, you're limited to white or very light-colored items.

Heat transfer methods, particularly modern DTF, also deliver stunning color vibrancy and can handle intricate, full-color designs. Their knockout feature is the ability to print on any color fabric, including jet black. This is possible because they first lay down a layer of white ink, creating an opaque base that makes the colors on top pop, no matter what color the shirt is. For a closer look at this process, check out our guide on heat transfer printing for t-shirts.

Cost Analysis: Startup vs. Per-Unit

Alright, let's talk money. The financial picture for each method is very different, affecting both your initial setup cost and what you pay for every single print.

Startup Costs:

- Sublimation: You're looking at a higher initial investment. You'll need a dedicated sublimation printer (you can't use it for regular printing), special sublimation inks and paper, a quality heat press, and a stock of compatible polyester blanks.

- Heat Transfer (HTV): This has a famously low barrier to entry. A beginner can get started with just a vinyl cutter, a heat press, and some sheets of HTV. It’s one of the most accessible ways to start a custom apparel business.

Per-Unit Costs:

- Sublimation: Ongoing costs are for ink and paper. For large, full-coverage prints, ink consumption can make the cost-per-print higher than a simple, one-color vinyl design.

- Heat Transfer (HTV): The cost is directly tied to the amount of vinyl you use. A complex, multi-color design can get expensive and time-consuming fast, since you have to cut, weed, and press each color individually.

This is exactly where Direct-to-Film (DTF) comes in to bridge the gap. While the initial equipment cost is higher than a basic vinyl setup, the per-print cost for a complex, full-color design is often much lower and more efficient than a multi-layered HTV project. It gives you scalability without the material handcuffs of sublimation.

Analyzing Production Speed and Scalability

Beyond how a finished print looks and feels, the method you choose fundamentally shapes your day-to-day work, your efficiency, and ultimately, your ability to grow. When you stack up sublimation against heat transfer, the conversation always lands on a crucial question: how fast can you get an order out the door, and can you scale from one shirt to one hundred without pulling your hair out?

This isn't just about how long the heat press is running. It’s about the entire process, from opening the design file to packing the finished product.

The true speed of each process really hinges on the design's complexity and the order size. A simple, one-color vinyl name on a single shirt? That's lightning fast. But for a batch of ten mugs with a full-color photo, sublimation is way more efficient. Getting a feel for these workflow differences is what separates a smooth operation from a chaotic one.

Sublimation Workflow Efficiency

Sublimation is an absolute workhorse for batch production, especially for complex, full-color designs. It's a straightforward and highly repeatable process, which is exactly what you want when you need to make multiples of the same thing.

Once your design is printed on the transfer paper, the hands-on part is the same for every single item. A vibrant, detailed photograph takes the exact same time to press as a simple black logo. That consistency is a huge win for scaling up.

Imagine an order for 20 team jerseys, each needing a multi-color sponsor logo. With sublimation, you’d print 20 identical transfers, press each one, and you're done. The workflow is clean and predictable. Best of all, there’s no cutting or weeding, which completely eliminates the most tedious part of producing intricate designs.

The Heat Transfer Vinyl (HTV) Process

Heat Transfer Vinyl (HTV) is incredibly versatile, but it comes with manual steps that can really bog down production, especially when designs get complicated or order quantities climb. The workflow for even a single HTV garment has a few distinct stages you can't skip.

- Cutting: First, you have to send the design to a plotter to cut it from a sheet of vinyl.

- Weeding: Next comes the part everyone loves to hate—manually pulling away all the excess vinyl from around and inside your design. For detailed art, this step alone can take ages.

- Layering: If your design has multiple colors, get ready for more work. Each color has to be cut, weeded, and pressed separately, which adds a ton of time and introduces more room for error.

This step-by-step process makes HTV fantastic for one-off jobs, like adding a name and number to a single jersey. But trying to produce those 20 jerseys with a three-color logo using HTV? That would be a logistical nightmare of cutting, weeding, and carefully layering 60 separate vinyl pieces.

Key Insight: The real bottleneck with HTV isn't the pressing; it's the prep. Weeding vinyl is a task that just doesn't scale. This makes large orders with complex designs incredibly inefficient and, frankly, less profitable.

The Rise of DTF for Scalable Heat Transfers

This is where Direct-to-Film (DTF) completely changes the game. DTF expertly bridges the gap between sublimation’s material limits and vinyl's labor-intensive process, creating a powerful, scalable solution for full-color designs on almost any fabric.

With a Cobra DTF system, a complex, multi-color design gets printed onto a film sheet in a single pass. There is zero cutting and zero weeding. You just press the entire transfer onto the garment. It’s a workflow that gives you the material freedom of traditional heat transfers with the batch-production speed of sublimation.

Let’s go back to that order of 20 jerseys with the three-color logo. With DTF, you’d get 20 identical, ready-to-press transfers. The application is a single press for each jersey, making your production time almost identical to sublimation. The huge advantage? You can do this on cotton, poly-blends, or any color fabric you want. This makes DTF a far superior choice for any shop looking to scale up their full-color printing without being stuck with polyester.

Aligning Your Method with Market Demand

Picking between sublimation and heat transfer isn't just about the tech—it's a critical business decision that shapes what you can sell and who you're selling it to. The best equipment in the world won't make you a dime if you can't produce what people actually want to buy.

The key is to look at this choice through a commercial lens. Your production method should directly line up with the products your target audience is looking for and the kind of business you aim to build.

Sublimation for Performance and Permanence

Sublimation has really cornered the market in a few key areas where a permanent, high-performance print is the only option. Since the process actually infuses dye into polyester fibers, it has become the gold standard for some very specific, and profitable, product lines.

- Performance Sportswear: Think jerseys, leggings, and cycling gear. Sublimation is the undisputed champ here because the prints are completely breathable, stretch right along with the fabric, and will never crack or peel.

- Promotional Hard Goods: For things like custom mugs, mousepads, and phone cases, sublimation delivers a vibrant, scratch-proof finish that feels high-end and is built to last.

- All-Over-Print Apparel: The trend of full-coverage, photo-realistic designs on t-shirts and hoodies is a perfect fit for sublimation’s edge-to-edge printing capabilities.

Key Insight: Sublimation shines in markets where customers expect a premium, permanent design that feels like it's part of the product itself. If you're targeting athletes, corporate clients who need durable promo gear, or fashion brands wanting all-over prints, sublimation is a perfect match.

Heat Transfer for Versatility and Customization

On the other side of the coin, heat transfer methods like vinyl (HTV) and Direct-to-Film (DTF) serve the massive market for personalized cotton apparel and small-batch orders. Their biggest commercial advantage is their versatility with materials, which opens up a whole world of products that sublimation can't touch.

To really connect your printing method to what sells, you have to get good at identifying market trends for business growth. This is how you'll spot the gaps where heat transfer’s flexibility becomes your secret weapon.

These methods are a fantastic fit for:

- Personalized Cotton Apparel: The entire custom t-shirt industry was practically built on heat transfer. It’s the go-to for band merch, family reunion shirts, and small business uniforms on classic cotton tees.

- Event-Specific Gear: Got a local fun run this weekend and need 50 shirts printed fast? HTV and DTF are brilliant for quick-turnaround jobs.

- Small-Batch Merchandise: For creators and entrepreneurs, these methods are ideal for testing new designs on a wide range of products without a huge upfront investment.

You can see this commercial split in the market data. The heat-transfer paper market is valued at roughly USD 541.1 million for 2024, and sublimation papers already command nearly half of that (~47%). This tells us that while sublimation dominates the high-volume polyester world, other transfer types own the versatile cotton and mixed-fabric niches. You can dig deeper into the heat-transfer paper market trends to see the numbers.

Ultimately, your choice in the sublimation vs heat transfer debate should circle back to your business plan. Get clear on who you're selling to, what they want to buy, and the materials they prefer. When you match your method to the market, you're not just buying equipment—you're making a smart investment in your company's growth.

So, What's the Right Choice for Your Business?

Deciding between sublimation and heat transfer isn't really about which method is "better." It's about matching the printing technology to your specific business goals and the products you want to sell. Getting this right is crucial for setting your shop up for success.

Think of it this way: Sublimation is a specialist. It’s like a race car—absolutely unbeatable on its designated track (white or light-colored polyester) but completely out of its element anywhere else. Heat transfer, on the other hand, is your trusty all-terrain vehicle, ready to tackle just about any surface you point it at, from cotton and blends to dark fabrics.

When to Go All-In on Sublimation

You should invest in a sublimation setup if your business model is laser-focused on products that need ultimate permanence and photo-realistic vibrancy. It's the undisputed champion for shops specializing in:

- Performance Apparel: Think athletic jerseys, custom leggings, and any moisture-wicking gear where the print can't crack, peel, or obstruct the fabric's breathability. The ink becomes one with the fabric, so you can't even feel it.

- Promotional Hard Goods: For items like ceramic mugs, polymer-coated tumblers, coasters, and mousepads, sublimation delivers a durable, scratch-proof finish that looks incredibly professional.

- All-Over-Print Fashion: If you're creating full-coverage, edge-to-edge designs on 100% white polyester garments for boutiques or fashion brands, sublimation is the only way to go.

The bottom line? Sublimation is your go-to when your core products are full-color, permanent designs on polyester fabrics and polymer-coated hard surfaces. In these specific niches, its quality and durability are simply unmatched.

When Heat Transfer Makes More Sense

Choose a heat transfer method if your business thrives on variety, quick customizations, and catering to a wider audience. This is the ideal path if your game plan involves:

- Printing on Cotton: Let's face it, the custom apparel world runs on cotton and cotton blends. From band t-shirts to corporate polos and family reunion gear, heat transfer lets you serve this massive market.

- Offering Total Versatility: You want the freedom to print on literally any color garment—especially popular black and dark-colored shirts—and on a wide range of materials like canvas totes or denim jackets.

- Managing Small, Custom Jobs: Your business is built around one-off designs, adding personalized names and numbers, or handling small-batch orders that demand flexibility without a complicated setup.

The Smart Upgrade: When to Bring in DTF

For many growing shops, the decision is no longer just a two-way race between sublimation and heat transfer vinyl. Direct-to-Film (DTF) has changed the game, offering a powerful hybrid solution.

Jump to DTF when you need the stunning, full-color detail of sublimation but on the wide range of materials that heat transfer allows. DTF breaks you free from the "polyester-only" jail of sublimation and completely eliminates the painstaking process of weeding vinyl. This makes it a superior choice for scaling a modern apparel business that needs to print vibrant, soft, and durable designs on cotton, blends, and darks with incredible efficiency.

Frequently Asked Questions

Even after a side-by-side comparison, some specific questions always seem to come up when you're in the trenches deciding between sublimation and heat transfer. Let's tackle the most common ones to clear things up so you can move forward with confidence.

Can You Use Sublimation on 100% Cotton Shirts?

The short answer is a hard no. True sublimation is a chemical process that works by turning dye into a gas, which then bonds permanently with polymer fibers. 100% cotton is a natural fiber and simply doesn't have the synthetic makeup required for this infusion to happen. If you try, the ink will just sit on the surface and wash right out.

You might see workarounds like special sprays or sheets designed to coat cotton, but they rarely deliver. They usually create a noticeable texture and don't offer the same permanence as true sublimation, which defeats the whole purpose.

If you want to put stunning, full-color designs on cotton, your best bet is Direct-to-Film (DTF). It gives you the brilliant colors you're looking for but works beautifully on the fabrics you actually want to use. It’s a much more professional and reliable solution.

Which Method Is More Profitable for a Small Business?

This really comes down to your business model and the kind of jobs you're taking on. There isn't a single "more profitable" method.

Heat Transfer Vinyl (HTV) is often the winner for quick, one-off customizations. Think adding a name and number to a single jersey. The startup costs are low, and the profit margin on these simple, high-value jobs can be fantastic.

On the other hand, sublimation starts to pull ahead when you're doing small-to-medium batches. If a client orders 20 mugs for their team or a run of polyester performance shirts, sublimation shines. The workflow is faster since there's no weeding, and the premium, permanent finish lets you command a higher price, boosting your profit on the whole job.

Is Sublimation More Environmentally Friendly Than Heat Transfer?

Sublimation generally has a better reputation for being eco-conscious. It’s a completely dry process, so it uses zero water. It also produces very little waste—the transfer paper is often recyclable, and because the ink becomes part of the material, you're not adding a layer of plastic.

Heat transfer methods, particularly HTV, can create more waste. Every time you weed a design, you're left with a pile of plastic scraps that end up in the trash. That said, the real environmental impact for either method comes down to the specific inks and materials you buy and how you manage waste. Opting for eco-friendly consumables can make a big difference, no matter which printer you're running.

Ready to print vibrant, full-color designs on practically any fabric, with none of the limitations? Cobra DTF offers premium, USA-made Direct-to-Film transfers that combine the quality of sublimation with the incredible versatility of heat transfer. Get your ready-to-press transfers shipped the same day and take your custom apparel business to the next level.