Choosing the Best T Shirt Printing Method

Share

Figuring out the best t shirt printing method really comes down to what you're trying to create. There’s no single best option for everyone. If you’re printing a huge batch of shirts with a simple logo, screen printing is your most affordable bet. But for a one-off tee with a photorealistic image, Direct-to-Garment (DTG) is the clear winner. The right choice always balances what your design looks like, how many you need, and the type of shirt you're using.

How to Choose the Right T Shirt Printing Method

Diving into the world of custom apparel can feel a bit overwhelming at first. With so many techniques out there, each with its own quirks, knowing where to start is half the battle. Getting a handle on the top five methods is the first step to making a smart choice. Whether you're starting a brand, making a single gift, or outfitting your team, picking the right process ensures your design looks and feels just the way you imagined.

This isn't just a niche hobby anymore; it's a massive industry. The custom T-shirt printing market was valued at around $6.5 billion in 2024 and is expected to keep growing, thanks in large part to e-commerce and social media. This boom shows just how much people want unique, high-quality gear. You can learn more about the custom apparel market growth and what's driving it.

Comparing the Top Printing Options

The easiest way to make a decision is to see how each method stacks up against your project’s needs. Some techniques are all about speed and volume, while others are built for incredible detail. Think of it like picking a car: you wouldn't take a sports car off-roading, and you wouldn't enter a moving van in a street race. Every printing method has a job it’s designed to do perfectly.

To help you get started, here's a quick side-by-side look at the five leading printing techniques.

Quick Guide to T-Shirt Printing Methods

| Printing Method | Best For (Order Size) | Design Complexity | Fabric Compatibility | Feel on Shirt |

|---|---|---|---|---|

| Screen Printing | Bulk (50+) | Simple, few colors | Cotton & Blends | Thick, slightly raised |

| Direct-to-Garment (DTG) | Single Items & Small Runs | Photorealistic, unlimited colors | 100% Cotton (best) | Soft, breathable, no feel |

| Direct-to-Film (DTF) | Small to Large Runs | Detailed, vibrant colors | Versatile (Cotton, Poly, Blends) | Smooth, flexible layer |

| Sublimation | Single Items & Small Runs | All-over prints, patterns | 100% Polyester (light colors) | Zero feel, part of the fabric |

| Heat Transfer Vinyl (HTV) | Single Items & Small Runs | Simple text, logos, numbers | Versatile (Cotton, Poly, Blends) | Varies, often thick layer |

Use this table as your starting point to narrow down the best options before we dig into the nitty-gritty of each method in the sections ahead.

Screen Printing: The Gold Standard for Bulk Orders

When you think of a classic printed t-shirt, chances are you're picturing screen printing. This technique is the undisputed champion for large-scale production, known for creating vibrant, tough-as-nails designs that last. It's the method behind concert merch, company uniforms, and event staff shirts for a good reason—it’s built for volume.

The process itself involves pushing thick layers of ink through a stenciled mesh screen directly onto the fabric. Here’s the key part: each color in a design needs its own unique screen, which has to be meticulously prepared and aligned. Once all the colors are down, the shirt is cured with heat, which permanently bonds the ink to the fibers. This creates a slightly raised, professional finish that feels substantial and holds up incredibly well over time.

The Economics of Scale

The real power of screen printing is all about volume. While the initial setup for creating and aligning the screens can be time-consuming and add to the cost, that expense gets spread across the entire order. As the number of shirts goes up, the cost per shirt goes way down.

This is what makes it the best t shirt printing method for orders of 50, 100, or even thousands of shirts. Trying to screen print just a handful of tees? The setup fees will make it wildly impractical. But if you need 500 identical shirts for a big event, no other method can touch its price point.

Key Insight: Screen printing's pricing model heavily favors bulk. The more you print, the cheaper each individual shirt becomes, making it the industry standard for large-scale apparel projects.

This economic advantage is a huge reason why screen printing still dominates the custom apparel industry. Even in 2024, it holds a massive 53.9% of the global market share, thriving where its efficiency and quality really shine. Its knack for producing sharp, punchy designs that don't fade after a few washes cements its top spot. You can dig into more data on the custom t-shirt printing market to see its lasting impact.

Quality and Durability

Screen printing delivers a level of vibrancy and durability that’s tough to beat. The inks are thick and opaque, which means you get bold, bright colors that really pop, especially on dark-colored shirts. Because the ink layer sits on top of the fabric and is cured right into it, the design is highly resistant to fading, cracking, and peeling.

A well-made screen-printed shirt can easily handle dozens of washes without the design falling apart, which is perfect for:

- Work Uniforms: Garments that need to stand up to daily wear and frequent laundering.

- Band Merchandise: High-quality apparel that fans will want to wear for years.

- Sports Team Apparel: Durable prints that can take a beating during physical activity.

This longevity gives a professional look that lasts, which is a great reflection on any brand or organization.

Understanding the Limitations

For all its strengths, screen printing isn't the right call for every single project. Its biggest drawback is how it handles complex, multi-color designs. Since every color requires a separate screen, designs with tons of colors, smooth gradients, or photorealistic details get complicated and expensive—fast.

Here’s a quick breakdown of when you might want to look at other options:

| Situation | Why It's a Limitation | Better Alternative |

|---|---|---|

| Photographic Images | The screen stenciling process can't replicate the fine dots and smooth tones needed for photos. | DTG or DTF |

| Designs with Many Colors | Each extra color adds to the setup time and cost, making it uneconomical for designs with 6+ colors. | DTG or DTF |

| Small Orders (Under 20) | High setup costs make the per-shirt price way too high for just a few items. | DTG or Vinyl |

| "Soft Hand" Feel Required | The thick ink layer can be felt on the shirt, which isn't always the desired feel for fashion or retail items. | DTG or Sublimation |

At the end of the day, screen printing is still a top contender for the best t shirt printing method when your priorities are cost-efficiency at scale, rock-solid durability, and vibrant colors for designs with a limited palette. It’s a tried-and-true workhorse that delivers professional results when you need to go big.

Direct-to-Garment (DTG): The Go-To for Complex, Colorful Designs

Think of DTG printing as a highly specialized inkjet printer for fabric. Instead of paper, you're printing a detailed photograph or a complex piece of art directly onto a t-shirt. This technique uses water-based inks that soak into the garment's fibers, allowing for stunning, full-color designs with incredible precision.

The real game-changer here is the lack of setup. Unlike screen printing, which requires creating a separate screen for every color, DTG has virtually zero setup costs per design. This makes it the best t shirt printing method for one-off custom pieces, small batches, and the entire print-on-demand business model. It opens the door for artists and designers to reproduce intricate artwork with unlimited colors and gradients without compromising their vision.

Why Fabric Choice is Everything with DTG

I can't stress this enough: the fabric you choose will absolutely make or break your DTG print. The water-based inks are specifically formulated to be absorbed by natural fibers. This is why DTG truly shines on 100% cotton garments, where it delivers vibrant, eye-popping colors and a super-soft finish. You can't even feel the ink.

When printing on dark shirts, the process gets a little more involved. It requires a pre-treatment spray followed by a white underbase layer. This base acts like a primer on a dark wall, ensuring the colors on top pop instead of getting lost in the dark fabric.

But this reliance on cotton is also its biggest weakness. DTG just doesn't play well with synthetics like polyester. The ink simply won't bond correctly to the fibers, which leaves you with a faded, blotchy mess.

Critical Insight: For the best possible DTG print—one that’s vibrant, detailed, and lasts—stick with high-quality, 100% ring-spun cotton. While blends can work, you should expect a more vintage, faded look as the cotton percentage goes down.

When DTG Is the Clear Winner

DTG has carved out a massive space in the custom apparel world, particularly for startups and independent creators. It allows for quick turnarounds and small production runs without needing a huge upfront investment. As technology keeps improving, it’s only getting more efficient, which is a key driver in the growth of the custom T-shirt market.

So, when is DTG the perfect tool for the job?

- Photorealistic Images: If your design is a detailed photograph or has subtle color gradients, no other method can capture it so faithfully on a cotton shirt.

- Artist Merchandise: It's a dream for artists selling their work. DTG captures every brushstroke and color nuance perfectly.

- Personalized Gifts: Need a single, unique t-shirt for a birthday or event? DTG makes it easy and affordable.

- Print-on-Demand Stores: This is the backbone of the POD model. E-commerce sellers can offer a huge catalog of designs without ever touching inventory, since each shirt is printed only when it's ordered.

Understanding DTG's Durability and Limitations

For all its strengths in detail and flexibility, DTG isn't without its drawbacks. The main one I hear about is durability. A DTG print feels incredibly soft and breathable because the ink is in the fabric, not sitting on top of it. However, it’s generally not as bulletproof as a screen-printed design. Over many washes, the colors can start to fade, especially if you wash it in hot water or blast it in a hot dryer.

DTG is also the wrong choice for bulk orders. The per-shirt print time is much slower than screen printing's high-volume, assembly-line process. Trying to print 100 shirts with the same design would take forever and cost a fortune compared to screen printing.

| Scenario | Why DTG is the Wrong Fit | Better Alternative |

|---|---|---|

| Large Batch Orders (50+) | Slower print time per shirt makes it inefficient and pricey at scale. | Screen Printing |

| Printing on Polyester | Water-based inks just don't stick to synthetic fibers. The result is poor. | Sublimation or DTF |

| When Max Durability is Key | The print is more susceptible to fading over many washes than thicker inks. | Screen Printing or DTF |

| Simple, Bold Logos (in Bulk) | It works, but it's not the most cost-effective method for simple designs. | Screen Printing or Vinyl |

At the end of the day, DTG is a phenomenal technology when you use it for what it was designed for. If you need high-detail, full-color designs on cotton for small runs or single items, it's easily one of the best printing methods out there.

A Head-to-Head Comparison of Printing Methods

When it comes to T-shirt printing, you need a straight-up, honest look at how each method performs in the real world. Let’s move past vague pros and cons and get into a practical, side-by-side analysis. We’re going to see how screen printing, DTG, DTF, sublimation, and vinyl really stack up on the things that matter most: your bottom line and your brand's reputation.

We'll be judging them on five critical battlegrounds: cost, durability, quality, fabric compatibility, and production speed. By the end, you'll have a clear picture of which tool is right for your specific job.

Cost Per Unit: Small vs. Large Orders

Cost is usually the first question on everyone's mind, but the answer is rarely simple. A method that’s a bargain for a single shirt can become a budget-buster for 500, and the reverse is just as true. The trick is to understand how setup costs and per-unit prices scale with volume.

-

For a small run (10 shirts): DTG and Heat Transfer Vinyl (HTV) are your most cost-effective bets. They have next to no setup costs, which makes them perfect for one-offs, prototypes, or testing out a new design. Screen printing, on the other hand, would be incredibly expensive here because you'd be paying for screen creation for just a handful of shirts.

-

For a large run (500 shirts): Screen printing is the undisputed champion of bulk orders. The significant setup cost gets spread so thin across hundreds of units that the price per shirt plummets. At this scale, DTG and DTF are more expensive because their cost per shirt doesn't change much, whether you print one or one thousand.

Key Differentiator: Screen printing's entire economic model is built for scale, making it unbeatable for large orders. For small, custom jobs, digital methods like DTG and DTF deliver far better value by cutting out the setup fees entirely.

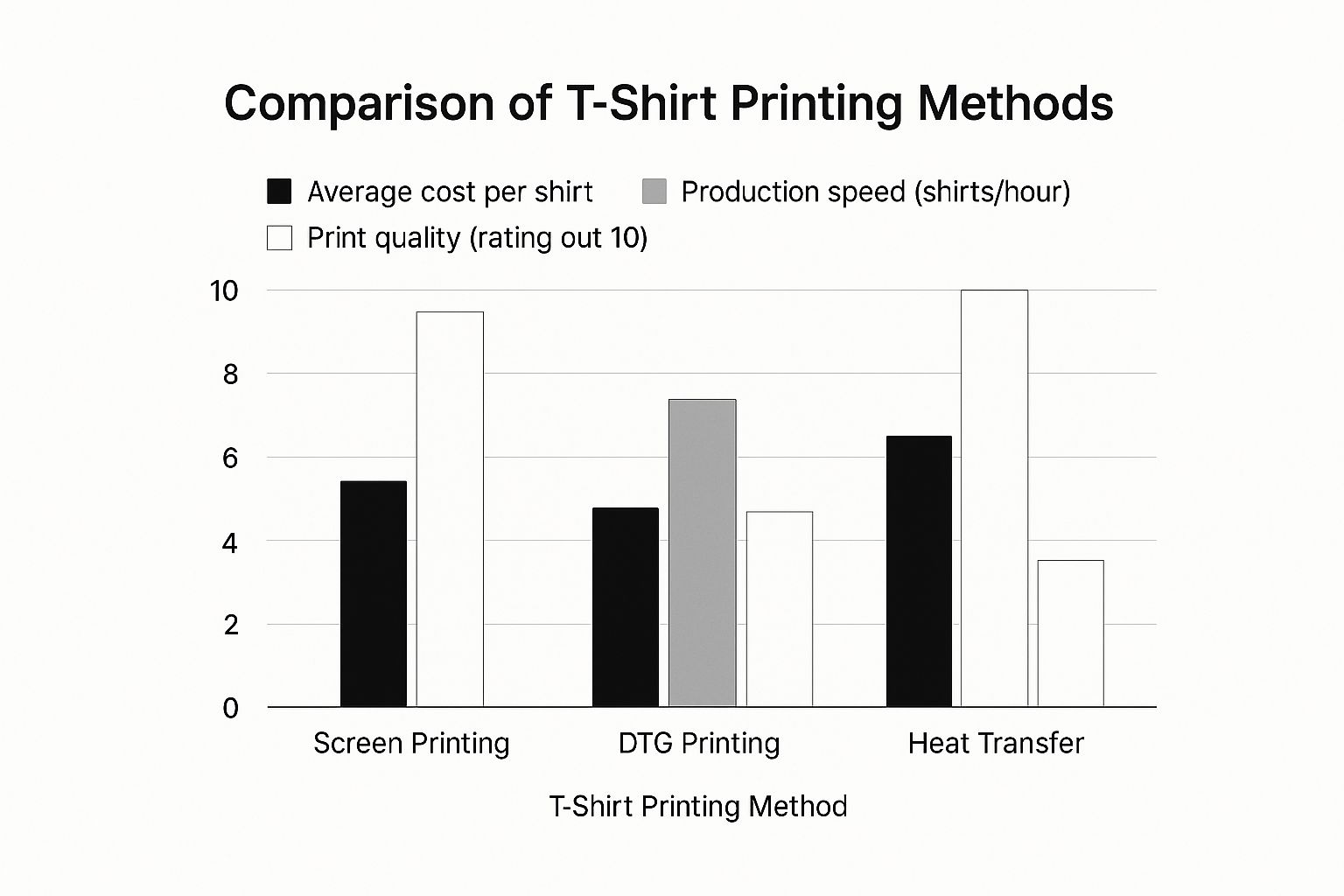

This infographic gives you a quick visual snapshot of how the three most popular methods compare on cost, speed, and quality.

As you can see, screen printing pulls ahead on speed and cost for bulk jobs, while DTG shines when it comes to print quality for more detailed, smaller orders.

Quality and Detail: Fine Lines vs. Solid Colors

Print quality isn't just about how it looks fresh off the press; it’s about how well a method captures the essence of your design. Some techniques are masters of photorealism, while others are built for bold, graphic statements.

-

Fine Lines & Gradients: DTG is the artist in this category. It works just like a high-resolution inkjet printer but for fabric, allowing it to nail photographic details and subtle color blending with amazing accuracy.

-

Large Blocks of Color: Screen printing delivers a punch. It lays down thick, opaque ink that results in unparalleled vibrancy and solid coverage, especially on dark garments. The result is a bold look that really pops.

-

Versatile Performer: DTF printing is a fantastic middle ground. It produces sharp, vibrant images on a special film which is then heat-pressed onto the shirt. This process helps it hold detail beautifully across a huge variety of fabrics. When you're looking into DTF vs. DTG printing, a major advantage for DTF is its ability to stay vibrant on polyester and other synthetic blends.

Durability and Feel After 20 Washes

A brilliant design that cracks or fades after a few washes is a letdown for everyone. Durability is all about longevity and how the print actually feels against the skin. We’ve rated each method on a 10-point scale based on how they hold up after about 20 wash cycles.

Here is a comprehensive breakdown to help you compare each method across several key factors.

Detailed T-Shirt Printing Method Comparison Matrix

| Criterion | Screen Printing | Direct-to-Garment (DTG) | Direct-to-Film (DTF) | Sublimation | Heat Transfer Vinyl (HTV) |

|---|---|---|---|---|---|

| Durability (out of 10) | 9/10 (Extremely durable, can outlast garment) | 6/10 (Good, but prone to fading without proper care) | 8/10 (Excellent, flexible and resistant to cracking) | 10/10 (Permanent, becomes part of the fabric) | 7/10 (Good, but can peel or crack over time) |

| Feel on Shirt | Slightly thick, raised layer | Very soft, breathable, almost no feel on light fabrics | Smooth, flexible, slightly rubbery feel | Zero feel, undetectable to the touch | Distinct layer, can be stiff depending on vinyl type |

| Best For | Large runs (50+), simple designs, band merch, uniforms | Small runs, full-color photos, complex designs, one-offs | All fabrics (cotton, poly, blends), vibrant graphics | 100% light-colored polyester, performance wear | Names, numbers, simple logos, custom one-offs |

| Cost (Small Run, <25) | Very High | Low | Low-Medium | Medium | Low |

| Cost (Large Run, 100+) | Very Low | High | Medium | Medium-High | High |

| Fabric Compatibility | Excellent on cotton & blends | Best on 100% cotton; limited on polys | Excellent on cotton, polyester, blends, and more | 100% polyester only (light colors) | Excellent on cotton, polyester, blends, even leather |

| Color Vibrancy | Excellent, very opaque | Good on light shirts, can be muted on darks | Excellent, bright and vibrant on all colors | Excellent, colors are infused into the fabric | Excellent, bold and opaque colors |

This matrix shows that while sublimation scores a perfect 10/10 for durability, its use is limited to polyester. Screen printing is a close second and far more versatile. DTG offers the softest feel but requires more care to maintain its look.

Fabric Versatility

Your choice of T-shirt material can instantly rule out certain printing methods. A bad pairing can lead to faded colors, prints that won't stick, or designs that wash out on the first cycle.

-

Best for Cotton: DTG is a cotton specialist, delivering its best results on 100% cotton. Screen printing is also a fantastic choice for cotton and most cotton blends.

-

Best for Polyester: Sublimation was born for this. It's designed exclusively for light-colored, 100% polyester fabrics. The chemical process of turning ink into gas simply doesn't work with natural fibers.

-

The All-Rounders: DTF and Heat Transfer Vinyl are the swiss army knives of printing. They can be applied to cotton, polyester, blends, and even tricky materials like nylon or leather, making them incredibly flexible options.

Speed and Scalability

How fast can you get your shirts made? The answer comes down to both the initial setup time and the printing rate per hour.

-

Fastest Setup: DTG and Vinyl win this race easily. With virtually no prep work, you can go from a digital file to a finished, one-of-a-kind shirt in just a few minutes.

-

Fastest Production Output: Once the screens are prepped and on the press, screen printing is an absolute workhorse. A good team can crank out hundreds of shirts per hour, making it the go-to for hitting tight deadlines for events or large retail orders.

-

Balanced Approach: DTF offers a smart mix of speed and flexibility. You print your designs onto transfer films in batches, which can then be applied quickly with a heat press as orders come in. This gives it great scalability for small to medium-sized businesses that need a versatile solution.

DTF and Sublimation: The Specialists

While screen printing and DTG get a lot of the spotlight, two other methods have carved out essential roles in the custom apparel world. Direct-to-Film (DTF) and Dye-Sublimation are both incredible technologies, but they’re not interchangeable. Think of them as specialists—you call on them for very specific jobs where they outperform everything else.

To really get it, you have to understand how they work. One is a master of versatility, and the other is the undisputed champion of permanence.

Direct to Film: The Ultimate All-Rounder

Direct-to-Film, or DTF, is the industry's problem-solver. It neatly bridges the gap between other methods, giving you the kind of vibrant, full-color detail you’d expect from DTG but with the freedom to print on almost any fabric.

The process itself is pretty slick. We print your design onto a special PET film, apply a powdered adhesive, and then use a heat press to transfer it onto the shirt. The result is a crisp, brilliant transfer that feels smooth and flexible.

What makes DTF a game-changer is its incredible fabric compatibility. It blows the doors off the limitations of other methods.

- Cotton and Blends: Colors pop with a bright, solid finish.

- Polyester and Synthetics: The bond is incredibly strong, making it a go-to for athletic apparel.

- Dark Garments: This is where DTF really shines. It produces stunningly bright whites and colors on black or dark shirts, no pre-treatment needed.

This "print on anything" capability makes it a favorite for shops that handle a huge variety of jobs. The finished print has a unique, almost soft-plastic feel that stretches without cracking and is ridiculously durable—it’ll often outlive the shirt itself. If you want to get into the nuts and bolts, our guide on what is Direct-to-Film printing breaks down the entire process.

Dye-Sublimation: The Master of Permanence

Dye-sublimation is less about printing on top of a shirt and more about printing into the fabric itself. It’s a bit of a science experiment, really. We use special inks that, when heated, turn into a gas and chemically bond with the fabric's fibers on a molecular level.

The outcome is a print you literally cannot feel. Run your hand across it, and it feels just like the original material. Because the ink is now part of the fabric, the design is 100% breathable and will never crack, peel, or fade. Ever. This is why it’s the king of performance wear and all-over prints.

Key Insight: Sublimation doesn't just sit on the fabric; it becomes part of it. This fusion guarantees unmatched durability and a completely weightless, breathable finish—perfect for high-endurance sportswear or massive, edge-to-edge graphics.

But here’s the catch, and it's a big one: sublimation has very strict rules. It only works on 100% polyester garments, and they have to be white or very light-colored. The inks are translucent, so they need a light background to show up, and the chemical process just won't work on natural fibers like cotton.

When to Use DTF vs. Sublimation

So, how do you choose? It’s simple: let the fabric and the job dictate the tool. These two methods are not competitors; they’re specialists for different scenarios.

| The Job | The Right Method | Why It’s the Clear Winner |

|---|---|---|

| Full-color logos on company work polos (cotton/poly blends) | DTF | DTF is the only choice here. It bonds perfectly to blended fabrics, delivering a sharp, durable logo that can handle the abuse of daily wear. |

| Edge-to-edge design on a team's soccer jerseys | Sublimation | This is sublimation's home turf. The ink becomes part of the polyester, so the design stays breathable and won't hinder the fabric’s moisture-wicking properties. |

| Small-batch run for a brand with tees, hoodies, and hats | DTF | DTF’s versatility is the hero. You can print the exact same vibrant graphic across cotton, polyester, and blended items for a consistent look. |

| Custom photo on a light-colored running shirt | Sublimation | For photorealistic detail on performance wear, nothing beats sublimation. The image becomes a permanent, weightless part of the shirt, so it never feels heavy or sticky. |

In the end, both DTF and sublimation can be the best t shirt printing method—as long as they’re used for the right project. DTF brings incredible versatility for printing on just about anything, while sublimation delivers untouchable permanence and feel, but only on polyester.

Matching the Printing Method to Your Project

Knowing the technical specs of each printing method is great, but the real skill is picking the right one for the job at hand. This is where we move from theory to practice, applying what you've learned to match your project's budget, quality standards, and creative vision.

Let's break it down into a few common scenarios to make the choice crystal clear.

For Entrepreneurs and Print-on-Demand Stores

If you're launching a brand from scratch or running a print-on-demand shop, flexibility is everything. You need to offer a wide range of designs without getting buried in inventory. For this, DTG and DTF are your best friends.

Both methods have virtually zero setup cost per design, so you can test new ideas freely. DTG is the master of photorealistic prints on 100% cotton, delivering incredible detail. On the other hand, DTF gives you the freedom to print on almost anything—polyester, blends, you name it—making it a ridiculously versatile option.

For Corporate Events and Bulk Merchandise

When you’re printing shirts for a company picnic, a 5K charity run, or a product launch, you need consistency and volume. This is where screen printing absolutely shines.

It’s built for scale. The more you print, the less you pay per shirt, making it the most cost-effective solution for any order of 50 pieces or more. You get a bold, durable print that looks sharp and professional across the entire batch.

The Takeaway: There's no single "best" method—it's all about context. DTG is perfect for one-off detailed prints. Screen printing is the undisputed champ for bulk orders. And for performance gear, sublimation is in a league of its own.

For Athletic Apparel and Performance Wear

For custom jerseys, workout gear, or any apparel that needs to breathe and stretch, dye-sublimation is the only way to go. The ink becomes part of the fabric itself, so the design has zero texture and will never crack, peel, or fade, no matter how many times it's washed.

This process ensures the garment's moisture-wicking and performance properties remain completely intact. The catch? It only works its magic on light-colored, 100% polyester fabrics. To really get why this is, check out our guide on cotton vs. polyester.

For One-of-a-Kind Gifts and Simple Customizations

Just need to make a single, special shirt for a birthday gift or add a name and number to a jersey? Your top choices are Heat Transfer Vinyl (HTV) and DTG.

HTV is fantastic for simple, bold graphics or text in one or two colors—it's fast, easy, and looks great. If you want to print a full-color photograph on a single tee, DTG is the answer. It produces a soft, retail-quality finish that makes for a truly personalized and memorable gift.

Your T-Shirt Printing Questions, Answered

Choosing the right printing method can feel overwhelming, but it usually boils down to a few critical factors. Let's tackle the questions we hear most often to help you make a confident choice.

What’s the Most Durable T-Shirt Printing Method?

When it comes to pure staying power, sublimation is in a league of its own. Because the ink is chemically bonded into the polyester fibers, the design literally becomes part of the fabric. It won't crack, peel, or fade, ever.

Hot on its heels is screen printing. The thick layer of plastisol ink is cured to create an incredibly tough, flexible layer on top of the shirt that can easily outlast the garment itself. It's the go-to for workwear and brand merch for a reason.

Which Printing Method Is Best for Photos?

For printing detailed, photorealistic images on cotton, nothing beats Direct-to-Garment (DTG). It operates just like a high-end inkjet printer for fabric, flawlessly recreating millions of colors and subtle tonal shifts.

If you're working with polyester, blends, or a mix of different fabrics, Direct-to-Film (DTF) is your champion. It delivers that same vibrant, high-fidelity result but with the versatility to work on almost any material.

Can I Print on Dark-Colored Shirts?

Absolutely, but the best method changes. Screen printing is a classic choice for dark garments, using thick, opaque inks that deliver a bold, vibrant finish.

Both DTG and DTF are also fantastic options. DTG printers lay down a white underbase first, which acts like a primer to make the colors on top really pop. DTF transfers are inherently opaque, so their vibrancy is guaranteed regardless of the shirt color you put them on. The only method that's a no-go here is sublimation, as it's a transparent dye process that only works on light-colored polyester.

Ready to create stunning, durable designs on any fabric? Trust Cobra DTF for premium, American-made DTF transfers that ship in 1-3 days. Elevate your apparel at https://cobradtf.com.