Sublimation Printing vs Heat Transfer a Guide for Creators

Share

It all boils down to one key difference: sublimation printing actually dyes the fibers of the fabric. The ink becomes part of the material, so you get a permanent, vibrant design that you can't even feel. On the other hand, heat transfer lays a design on top of the fabric. This method gives you incredible versatility, letting you print on all sorts of materials like cotton and even dark-colored shirts.

So, the choice really hinges on what you value more—the seamless feel and permanence of sublimation or the broad material flexibility of heat transfer.

Comparing the Core Concepts

When you're weighing sublimation printing vs. heat transfer, you're looking at two totally different ways of getting a design onto a product. One is a chemical reaction that permanently infuses dye into the material itself. The other is more of an application, bonding a physical layer onto the surface.

Getting this distinction right is the first step to choosing the best method for your goals, whether you're working on a personal project or launching a new product line. For anyone exploring creative ventures, checking out different business ideas for ecommerce can really highlight where custom printing fits into a profitable business model.

This guide will walk you through everything that matters. We'll break down:

- The actual step-by-step process for each technique.

- Which materials work best and what limitations to expect.

- How the final design holds up, looks, and feels.

- Practical, real-world examples to help you decide.

- What to expect in terms of startup and ongoing costs.

To kick things off, here's a quick look at the main differences side-by-side.

Quick Comparison Sublimation vs Heat Transfer

This table gives you a high-level overview of how these two methods stack up across the most important factors. It’s a great starting point for figuring out which one aligns with your specific project needs.

| Attribute | Sublimation Printing | Heat Transfer |

|---|---|---|

| Process | Ink turns into a gas and bonds with polymer fibers. | A design is applied to the surface with an adhesive layer. |

| Best For | Light-colored polyester fabrics and polymer-coated hard goods. | Cotton, blends, polyester, and both light and dark materials. |

| Feel of Design | No feel at all; the ink is part of the fabric. | A tangible layer on top of the fabric (can vary by type). |

| Durability | Extremely durable; will not crack, peel, or fade. | Good durability but can crack or peel over time with washing. |

| Color Vibrancy | Excellent for photorealistic, full-color gradients. | Great for solid colors and opaque graphics, especially on darks. |

As you can see, there isn't one "best" method—it completely depends on the final product you envision. Now, let's dive deeper into the specifics.

How Sublimation Printing Works

Think of sublimation less like printing and more like a chemical reaction. At its heart, the process uses special dye-sub inks that have a unique property: when hit with high heat and pressure, they skip the liquid phase and turn directly from a solid into a gas. This gas then seeps into the surface of the material, creating a permanent bond with its fibers.

This is a fundamental difference when you're looking at sublimation printing vs heat transfer. You aren't just laying down a layer of ink on top of the fabric. Instead, the ink actually becomes part of the substrate. The result is a design with absolutely no feel—what we in the industry call "zero hand." Because it's infused into the material, it won't crack, peel, or fade, no matter how many times you wash it. This is why sublimated products are famous for their incredible durability and stunning, photo-quality finish.

Essential Equipment and Materials

Pulling off this infusion process requires a very specific toolkit. You can't just grab any old printer and get to work; there are some non-negotiables you'll need for a successful sublimation setup.

- A Sublimation Printer: You need a dedicated machine built for this, like the popular Epson F170. Your standard office inkjet just won't cut it.

- Sublimation Inks: This is the magic ingredient. These inks are specially formulated to vaporize under heat.

- Sublimation Paper: A specialty coated paper designed to hold the ink in solid form and then release it cleanly as a gas when heated.

- A Heat Press: This is what provides the consistent, high temperature (usually around 380-400°F) and even pressure needed to make the sublimation magic happen.

- Polyester or Polymer-Coated Substrates: This is the big one. Sublimation only works on materials that are either made of polyester or have a special polymer coating.

Key Insight: Sublimation doesn't print on a material; it prints into it. The dye physically bonds with the polyester molecules, resulting in a permanent image that feels exactly like the original fabric or surface.

This unique requirement is also the process's main limitation. Since the ink is transparent and essentially dyes the fibers, it only shows up properly on white or very light-colored items. If you want to get into the nitty-gritty, our complete guide on what is sublimation printing covers all the details.

The demand for these kinds of high-quality, personalized products is booming. The global dye sublimation printing market recently hit a valuation of around USD 16 billion, with the Asia Pacific region dominating thanks to its massive textile industry. It's a testament to just how popular this vibrant and long-lasting printing method has become across the globe.

Getting to Grips with Heat Transfer

While sublimation dyes the very fibers of a fabric, the heat transfer method is a bit more straightforward. It involves applying a design from a carrier material—think special paper or a sheet of vinyl—directly onto the surface of a product using a heat press. You can almost think of it as a professional, incredibly durable version of the iron-on transfers you might remember.

This distinction is at the heart of the sublimation printing vs heat transfer conversation. Because the design sits on top of the material instead of becoming part of it, heat transfer works on a much wider array of fabrics. That versatility is easily its biggest advantage.

The Many Forms of Heat Transfer

"Heat transfer" isn't just one single process; it's more of an umbrella term covering a few popular techniques. Each one brings something different to the table in terms of feel, look, and ideal use case.

- Heat Transfer Vinyl (HTV): This is all about cutting your designs out of colored vinyl sheets and pressing them onto your item. HTV is fantastic for bold, simple graphics, text, and logos. It creates a solid, opaque layer that pops, especially on dark-colored apparel.

- Printable Heat Transfer Paper: This technique lets you use a regular inkjet or laser printer to print full-color designs onto a special transfer paper. You then press the whole printed design onto the fabric. It’s the perfect way to get photorealistic images onto a cotton t-shirt.

This flexibility makes heat transfer a favorite for countless small businesses and crafters. For a beginner, a complete setup with a cutter, press, and some starter materials can often be put together for under $800.

The Bottom Line: The key thing to remember about heat transfer is its compatibility. It works beautifully on cotton, polyester, blends, canvas, and more. If you want to print on something that isn't polyester, heat transfer is almost always the answer.

The demand for these materials is a testament to their popularity. In 2023, the heat transfer paper market was already valued at roughly USD 550 million and is projected to skyrocket by 2033, largely thanks to the world's love for custom t-shirts. For a deeper dive into these numbers, you can check out the full heat transfer paper market research.

With this method, you can feel the design on the surface of the garment, though the thickness varies based on the material. Don't worry, modern materials are a world away from the stiff, cracking transfers of the past—they're now much softer and more pliable. If you're just getting your feet wet, our guide to heat transfer printing for t-shirts is a great place to start. Its accessibility and freedom from material constraints make it a real workhorse for creators.

When you're trying to decide between sublimation printing and heat transfer, it really boils down to three things: how long will the design last, how good does it look, and what does it feel like? These are the factors that separate a professional-quality product from an amateur one.

The core difference is simple but has massive implications. One method fuses ink directly into the fabric's fibers, while the other sticks a physical layer on top of it. That one distinction changes everything you can see and feel, right away and months down the line.

Lifespan and Durability Under Stress

This is where sublimation really pulls ahead. Because the ink literally becomes part of the polyester fibers, the design is as tough as the fabric itself. That means it will never crack, peel, or fade, no matter how many times you throw it in the wash. For items that get a lot of wear and tear—think sports jerseys or workout gear—sublimation is the undisputed king of longevity.

Heat transfer, on the other hand, relies on an adhesive layer that sits on the surface. Don't get me wrong, modern materials like a good quality Heat Transfer Vinyl (HTV) are surprisingly resilient. But they're still a layer on top of the fabric. After enough washes and stretches, especially without proper care, the design can start to show its age by cracking or peeling at the edges. The lifespan is decent, but it's not forever.

If you remember one thing, make it this: Sublimation becomes part of the fabric, while heat transfer sits on top of it. This single concept is the key to understanding their differences in durability.

Color Vibrancy and Visual Quality

Both techniques can produce some seriously eye-popping designs, but they shine in different scenarios. Sublimation is the master of photorealistic prints. The ink acts as a dye, allowing for perfectly smooth gradients and color blends. This results in incredibly vibrant, high-definition images that look like they were pulled straight from a professional photograph. The catch? The inks are transparent, so this amazing effect only works on white or very light-colored polyester fabrics.

Heat transfer, especially HTV, is your best bet for bold, solid colors that need to pop on any fabric, including black. It's the go-to for crisp logos, text, and graphics on dark-colored apparel. While you can use printable heat transfer paper for full-color images on cotton, it just can't match the seamless vibrancy and gradient quality of sublimation. So, you have to ask yourself what's more important: photorealism on a light shirt, or bold opacity on any color shirt.

The Hand or Feel of the Final Product

In the garment world, "hand" is shop talk for how a design feels to the touch. This is another area where sublimation and heat transfer are worlds apart.

A sublimated print has zero hand. That's right—you can't feel it at all. Run your hand across the design, and it feels exactly like the rest of the fabric. This creates an incredibly premium, breathable finish, which is perfect for all-over prints where comfort is non-negotiable.

A heat transfer design, however, always has a feel. You can physically sense the layer of vinyl or transfer paper on the shirt's surface. Modern materials are getting much softer and more flexible, but it’s still an additional layer. This can actually be a plus if you want a design with a bit of texture or a raised feel, but it's a critical factor to consider if a soft, lightweight feel is your main goal. The fabric choice also makes a huge difference; you can learn more about that in our guide to cotton vs polyester.

To help you visualize these differences, here's a side-by-side breakdown of the key features. This table will help you quickly assess which method aligns best with the specific needs of your project.

Detailed Feature Comparison Sublimation vs Heat Transfer

A detailed comparative analysis of crucial features to guide the decision-making process for different project requirements.

| Feature | Sublimation Printing | Heat Transfer | Key Takeaway |

|---|---|---|---|

| Durability | Permanent; will not crack, peel, or fade. Lasts the lifetime of the garment. | Good, but finite. Can crack or peel over time with repeated washing and wear. | Sublimation is unbeatable for longevity, especially for items washed frequently. |

| Color Quality | Extremely vibrant, photorealistic prints with seamless gradients. | Bold, opaque colors that show up well on any fabric color. | Sublimation excels at full-color images on light fabrics; HTV is best for solid graphics on darks. |

| Feel ("Hand") | Zero hand; cannot be felt on the fabric. The print is part of the material. | Tangible; you can feel the layer of material on top of the fabric. | Choose sublimation for a soft, premium feel. Heat transfer has a noticeable physical presence. |

| Fabric Compatibility | Works only on polyester or poly-coated materials (minimum 65% polyester). | Versatile; works on cotton, polyester, blends, and more. | Heat transfer is the clear winner for fabric flexibility, especially for natural fibers like cotton. |

| Fabric Color | Best on white or very light-colored fabrics only. | Works on any color fabric, including black and other darks. | If you're printing on dark garments, heat transfer is your only viable option. |

Ultimately, looking at this comparison makes it clear that the "better" method really depends on what you're trying to create. Each one has distinct strengths that make it the perfect choice for certain jobs and the wrong choice for others.

When to Use Sublimation vs. Heat Transfer

Alright, we've covered the technical details. Now for the most important part: deciding which method to actually use for your project. This isn't about which one is "better" overall, but which one is the right tool for the job at hand.

The decision really boils down to four things: the material you're printing on, the color of that material, how complex your design is, and how many you're making. Getting this right is the difference between a professional product that lasts and a design that peels, fades, or just feels wrong.

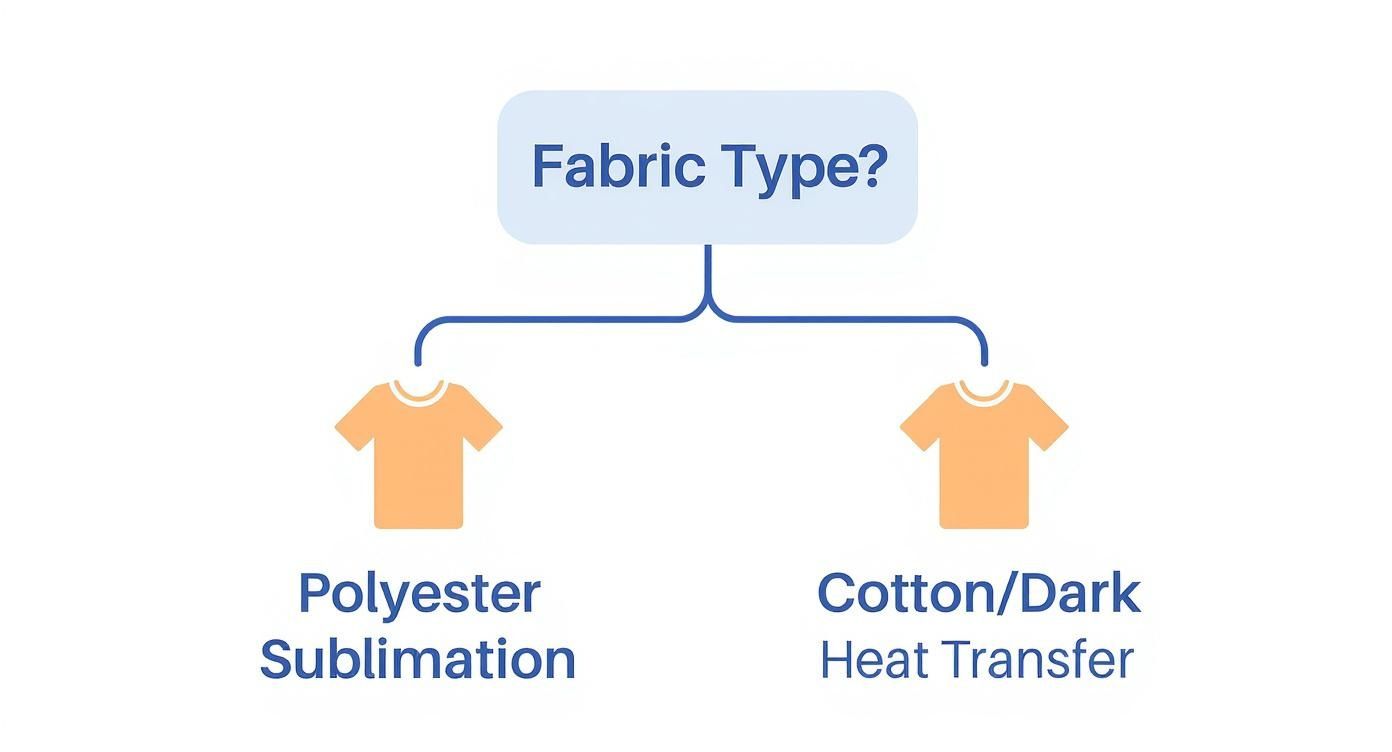

Let's walk through some real-world scenarios to make this choice crystal clear. This simple chart can be your first gut check, as it zeroes in on the most crucial starting point: your fabric.

As you can see, the material is the first fork in the road. Answering that question will immediately narrow down your options.

Choose Sublimation for These Projects

Sublimation is your go-to when you need unbeatable vibrancy and durability, with a design that has absolutely no feel to it. The way the ink becomes part of the material makes it the clear winner for high-end and performance-focused items.

- Athletic Jerseys and Performance Wear: Think about soccer jerseys or marathon shirts. Breathability is everything. Sublimation dyes the polyester fibers directly, so it doesn't add a layer on top that would block the fabric's moisture-wicking capabilities. Team logos will be bright and sharp, and they’ll never crack or peel, no matter how many times they go through the wash.

- Custom Mugs and Hard Goods: Sublimation isn't just for apparel. For a permanent, dishwasher-safe image on a polymer-coated mug, water bottle, or phone case, this is the only process that truly works. The print is completely scratch-resistant because it's infused into the coating, not sitting on top of it.

- All-Over-Print T-Shirts: If you want a design that seamlessly covers an entire garment from edge to edge, sublimation is the only way to achieve that premium, retail-quality look. You get a flawless print with zero texture, something heat transfers can't come close to replicating.

Opt for Heat Transfer in These Scenarios

Heat transfer is the flexible, reliable workhorse of the custom printing world. It's your problem-solver, especially when sublimation just isn't an option.

Key Takeaway: If you're working with cotton or any dark-colored garment, heat transfer is your method. Period. Sublimation ink is transparent and requires a white or light-colored polyester base to show up correctly.

Heat transfer is the perfect choice for these common jobs:

- Cotton Band T-Shirts or Hoodies: The classic concert tee is almost always 100% cotton. Heat Transfer Vinyl (HTV) is ideal for applying those bold, solid-color band logos and tour dates that need to pop, especially on a black hoodie.

- Small Runs of Custom Logos: A local cafe needs just 15 aprons with their two-color logo. Firing up a screen printing press doesn't make sense, but HTV is perfect. It’s cost-effective for small batches and gives a clean, durable result.

- Personalized Canvas Tote Bags: Want to make unique gifts or promotional bags? Whether you're using simple text or full-color photos, heat transfer paper and vinyl work beautifully on natural fibers like canvas, where sublimation simply can't go.

Breaking Down the Costs and Investment

Let's talk money. When you're weighing sublimation printing vs heat transfer, your budget is often the deciding factor. Each method has its own financial footprint, from the initial equipment you need to buy to the day-to-day cost of materials. Getting a clear picture of these costs is crucial before you dive in.

If you're just starting out or want to dip your toes in the water, heat transfer is usually the more wallet-friendly path. You can get a solid beginner's setup—a decent craft cutter, a heat press, and some starter vinyl—for under $800. This low barrier to entry makes it perfect for hobbyists or small-scale sellers who aren't ready for a major investment.

Sublimation Startup Costs

Jumping into sublimation requires a bit more cash upfront. It’s not as simple as using any old printer; you need specialized gear from day one.

- Sublimation Printer: You'll need a dedicated printer, like an Epson F170, that's built for the job.

- Specialty Inks and Paper: These are your essential supplies. Regular ink and paper just won't work.

- Heat Press: A high-quality press is non-negotiable. Sublimation needs consistent, high heat to work its magic.

All in, a reliable entry-level sublimation setup will likely set you back somewhere between $1,000 and $1,500. That initial cost is a significant step up from a basic heat transfer vinyl kit, so it's something to plan for.

Ongoing Consumable Expenses

Once you're set up, the real long-term cost story unfolds in your material expenses. For sublimation, you're buying ink and paper. The good news is that the demand for these supplies is booming. The sublimation paper market is expected to hit USD 2.7 billion by 2035, thanks in large part to the textile industry. You can dig into the sublimation paper market trends from Future Market Insights to see why. This growing market helps keep the cost-per-print fairly competitive.

The Bottom Line: Sublimation costs more to get into, but a full-color print can actually be cheaper than a complex, multi-layered vinyl design. Heat transfer costs vary wildly with each project, depending entirely on the vinyl you choose.

With heat transfer, your ongoing expenses are all about the vinyl or transfer paper. A simple one-color design using standard HTV is incredibly cheap to produce. But start layering multiple colors or reaching for specialty vinyls like glitter, flock, or holographic, and your costs per item can climb quickly. You really have to price your work carefully to stay profitable.

Common Questions About Printing Methods

Even after walking through the nitty-gritty of each process, you probably still have a few questions rolling around in your head. It's totally normal. When you're weighing sublimation printing vs heat transfer, the same practical concerns tend to pop up time and again.

Let's clear the air and tackle those common points of confusion. Getting these answers straight can save you a ton of time, money, and headaches down the road.

Can I Use a Regular Inkjet Printer for Sublimation?

The short answer is a hard no—at least, not if it's ever had regular ink in it. Once a standard office inkjet has been used, the original ink contaminates the entire system. That contamination ruins the special chemical reaction that sublimation ink needs to turn from a solid into a gas.

The one exception? You can take a brand-new, never-used inkjet printer—certain Epson EcoTank models are popular for this—and fill it with sublimation ink from the get-go. Just know that this is a one-way street. Once you convert it, it's a dedicated sublimation printer for life.

Which Method Is Better for Beginners?

Heat transfer, especially Heat Transfer Vinyl (HTV), is almost always the easier entry point for anyone just starting out. The initial investment is a lot lower; you can get a decent starter setup for under $800. The process itself is also more forgiving.

You can use HTV on all sorts of affordable and easy-to-find items, like basic cotton t-shirts. Sublimation, on the other hand, has a steeper learning curve. It requires more precise color management and only works on polyester or special polymer-coated blanks, which isn't as intuitive for a newcomer.

Expert Tip: If you're just dipping your toes in, grab some HTV and a few cheap cotton tees. It’s a low-risk way to learn the ropes and build your confidence before you even think about the complexities of sublimation.

How Should I Wash These Garments?

How you care for the final product is crucial for its lifespan, and the rules are completely different for each method.

-

Sublimated Garments: These are incredibly low-maintenance. Since the dye is permanently fused into the fabric's fibers, the design won't crack, peel, or fade. You can throw them in the wash and dryer just like any other piece of clothing.

-

Heat Transfer Garments: These need a little more TLC. To protect the design, which sits on top of the fabric, you'll want to wash them inside out in cold water. Tumble dry on low, or better yet, hang them up to air dry. This gentle approach helps the adhesive last and keeps the design from looking worn out.

Here at Cobra DTF, our specialty is creating top-tier Direct-to-Film transfers that give you the best of both worlds—the versatility of heat transfer with that vibrant, soft-to-the-touch feel everyone loves. Our transfers are made right here in the USA, ensuring you get consistent, professional-grade results shipped quickly from our facility in Texas.

Check out our premium DTF transfers and see the difference for yourself.