Printing methods for t shirts: A Practical Guide

Share

Picking the right way to print a t-shirt really boils down to four things: how many you need, how complex your design is, the shirt's fabric, and of course, your budget. Whether you're making a single, eye-popping photo tee for a gift or a thousand shirts for your company event, the right technique makes all the difference in getting a look you love at a price that makes sense.

Choosing the Right T-Shirt Printing Method

Diving into custom apparel can feel a bit overwhelming at first. You'll hear printers throw around terms like screen printing, DTG, and sublimation, but what does that actually mean for your project? Here's the secret: there's no single "best" method. The perfect choice is always the one that fits your specific needs.

Think of it like picking a vehicle. You wouldn't take a slick sports car on a muddy, off-road adventure, and you wouldn't use a giant moving truck for a quick run to the grocery store. In the same way, the process for printing a huge run of simple event t-shirts is completely different from the one you'd use for a one-of-a-kind shirt with a detailed photograph on it.

To help you get started, here's a quick comparison of the most common methods.

At-a-Glance T-Shirt Printing Comparison

This table gives you a quick snapshot of the most popular t-shirt printing methods, helping you see which one might be the best fit for your project's goals.

| Method | Best For | Durability | Feel on Fabric |

|---|---|---|---|

| Screen Printing | Bulk orders (25+), simple designs with few colors | Excellent; lasts the life of the shirt | A slightly raised layer of ink |

| Direct-to-Garment (DTG) | Single shirts or small batches, full-color photos | Good; can fade over time with many washes | Very soft; ink is absorbed into the fibers |

| Heat Transfer Vinyl (HTV) | Simple graphics, names, numbers, small orders | Good; can crack or peel after many washes | A smooth, plastic-like layer on top |

| Sublimation | 100% polyester, all-over prints, full-color designs | Excellent; permanent, won't crack or fade | No feel at all; ink becomes part of the fabric |

Each of these has its place, and understanding the core factors behind your project will point you in the right direction.

Key Factors That Guide Your Decision

Before we get into the nitty-gritty of each technique, let's nail down the essentials that will steer your choice. Getting clear on these four points right from the start will make the whole process a lot easier.

- Order Quantity: Are you printing just one shirt or a run of 500? Some methods have high setup costs, making them great for bulk but expensive for a single item. Others are built for one-off prints.

- Design Complexity: Is your design a simple, one-color logo? Or is it a photorealistic masterpiece with millions of colors and subtle shading?

- Fabric Type: What's the shirt made of? Some inks work beautifully on 100% cotton, while others are specifically designed for polyester or blended fabrics. This is a non-negotiable for certain methods.

- Budget and Turnaround: How much are you looking to spend per shirt, and when do you need them in hand?

Answering these four questions is your shortcut. It helps you immediately filter out the wrong options and focus on the one or two methods that are a perfect match for what you're trying to achieve.

In this guide, we'll break down each of these printing styles, explaining the real-world pros and cons of old-school techniques and modern digital solutions. By the end, you’ll have the confidence to choose the right process to get a fantastic-looking shirt that's made to last.

Screen Printing: The Gold Standard for Bulk Orders

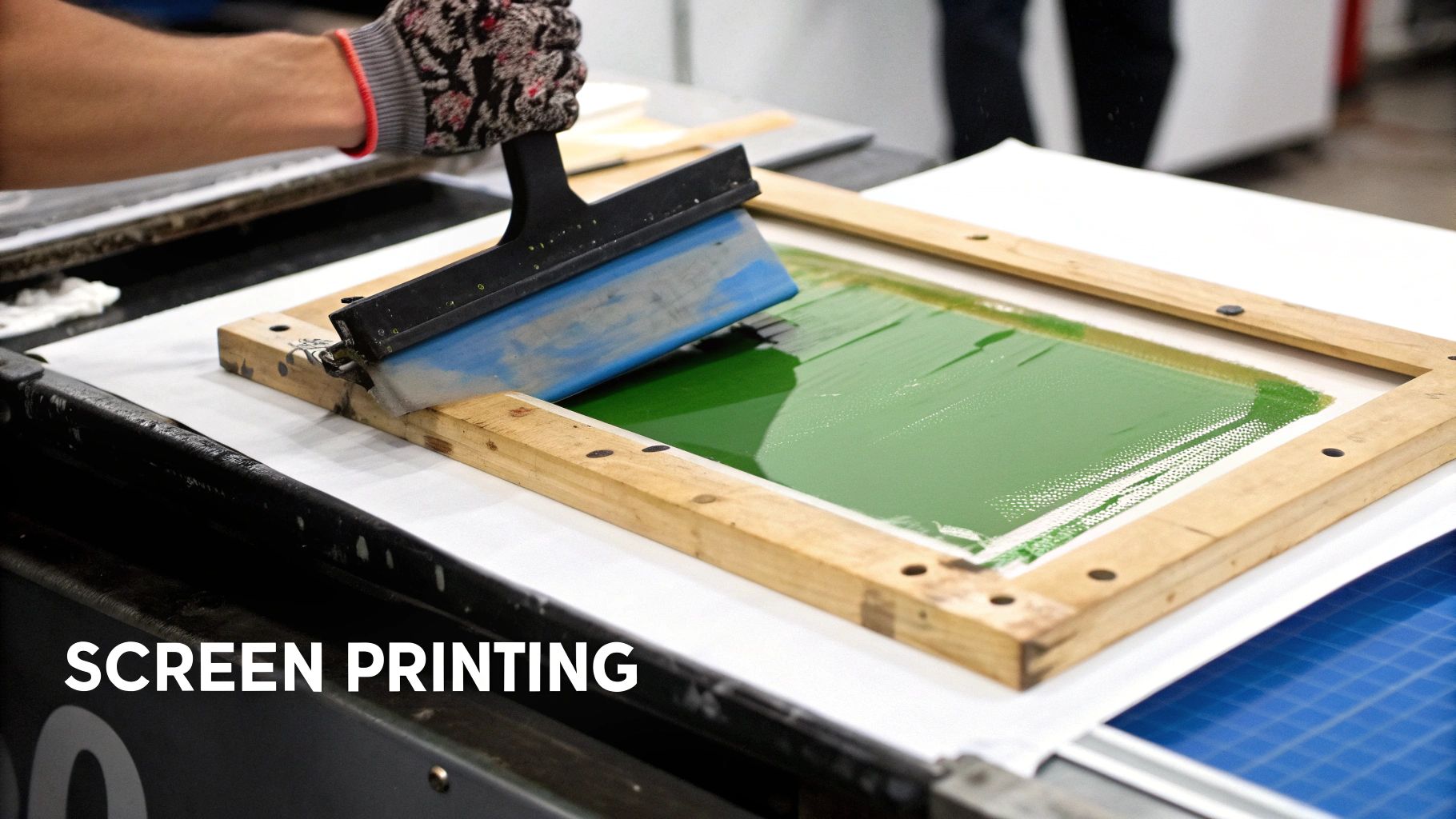

When you imagine classic t-shirt printing, chances are you're thinking of screen printing. It’s been the undisputed champion for large-scale production for decades, and for good reason. Think of it as a highly sophisticated stenciling process.

A fine mesh screen is stretched over a frame, and a stencil of your design is burned onto it. The printer then uses a squeegee to push thick, durable ink through the open parts of the stencil and directly onto the shirt. Each color in your design requires its own separate screen, and they're all layered one by one to create the final image.

This traditional technique still dominates the custom t-shirt world, holding a huge share of the market. Its popularity comes down to amazing cost-efficiency and the incredibly vibrant, long-lasting prints it produces, especially on cotton. You can dig deeper into the custom t-shirt printing market stats over on IMARC Group.

The Power of Volume

The real magic of screen printing kicks in when you need a lot of shirts. The initial setup—creating all those screens—takes time and has a cost. But once that's done, printing the shirts is incredibly fast and efficient. This makes it the absolute best choice for orders of 25 shirts or more.

Here’s the core principle: the more shirts you print, the less each one costs. That initial setup fee gets spread out across the entire batch, which brings the price-per-shirt way down.

Because of this economy of scale, screen printing is the go-to method for:

- Corporate Merchandise: Uniforms and promotional apparel for businesses.

- Event Apparel: T-shirts for concerts, festivals, and charity runs.

- Brand Merchandise: Consistent, high-quality shirts for clothing lines.

- Team Uniforms: Durable and vibrant gear for sports teams.

Advantages and Limitations

The number one advantage of screen printing is its durability. The thick layer of plastisol ink sits on top of the fabric and cures into a tough, flexible layer. It can handle countless washes without cracking, peeling, or fading. The colors are also incredibly bright and opaque, popping off the fabric even on the darkest shirts.

But, it's not perfect for every job. The need to create a separate screen for every single color makes it a poor fit for photorealistic images or designs with lots of gradients. That complexity and cost is also why it’s not practical if you just want a single custom t-shirt.

For designs with simpler graphics and solid colors, screen printing delivers a professional, tactile finish that other methods often try to imitate. It's the ultimate workhorse for getting bold, beautiful designs onto a lot of shirts without breaking the bank. To see how it compares to another popular option, check out our guide on silk screen printing vs heat transfer.

2. Direct-to-Garment (DTG) Printing for Detailed Designs

If screen printing is the tried-and-true workhorse for big batches, then Direct-to-Garment (DTG) printing is the meticulous artist. Think of it like your desktop inkjet printer, but built to handle fabric. Instead of sliding in a piece of paper, you load a t-shirt, and the machine gets to work.

The DTG printer sprays specialized, water-based inks directly onto the garment, which then soak into the fibers. This technique is what makes it possible to reproduce photorealistic images, complex illustrations, and designs with tons of subtle color gradients. The final print feels incredibly soft and breathable because the ink becomes part of the shirt, not just a layer sitting on top of it.

When to Choose DTG

The beauty of DTG printing lies in its lack of a complex setup. Screen printing needs a new screen for every single color, which takes time and money. DTG, on the other hand, can print a full-color masterpiece in one go, making it the undisputed champion for small orders and one-offs.

It's the perfect match for situations like these:

- One-of-a-kind custom shirts for a special gift, a personal project, or a memorable event.

- Small business merch when you’re testing a new design and don't want to commit to a huge inventory.

- Highly detailed artwork like photographs, paintings, or intricate graphics with a massive color palette.

- Quick prototypes to see exactly how a design will look on a shirt before you order a larger run.

By getting rid of the complicated prep work, DTG gives creators the power to bring incredibly detailed ideas to life quickly and affordably, even for a single shirt. That kind of flexibility is a true game-changer.

This ease of use is a big reason why digital methods are taking off. The digital segment of the t-shirt printing market is growing faster than any other, thanks in large part to technologies like DTG. For a closer look at the numbers, you can explore more about the growth of digital t-shirt printing.

Knowing the Downsides

Of course, no method is perfect. The main drawback with DTG is the cost per shirt, which is higher than screen printing when you start getting into large quantities. Because every shirt is printed individually, you don't get the same cost savings on bulk orders.

Another thing to keep in mind is the fabric. DTG inks are water-based and bond best with natural fibers. For the brightest, most durable prints, 100% cotton is the gold standard. While it can work on some cotton blends, it’s generally not the right choice for polyester or other synthetic materials.

Printing on dark-colored shirts also requires an extra step: laying down a white underbase first so the colors pop. This adds a little to the cost and print time. If you're weighing your digital options, looking at a complete breakdown of DTF vs DTG printing can help clarify which method is better suited for different fabrics and projects.

Heat Transfer Printing: The Go-To for Versatility

When you need flexibility, heat transfer printing is a fantastic option. At its core, the process is simple: a design is applied to a t-shirt using a combination of heat and pressure. Think of it as a professional-grade iron-on, but way more durable and sophisticated.

This method uses a special carrier sheet that holds your pre-printed design. A heat press then bonds that design directly onto the garment. This simple concept branches out into a few different techniques, but two of the most popular are Heat Transfer Vinyl (HTV) and Plastisol Transfers. While both end up under a heat press, how the design is made and what it’s best for are completely different.

Get Crisp, Bold Graphics with Heat Transfer Vinyl

You've definitely seen Heat Transfer Vinyl, or HTV, in action. It's the king of bold, simple graphics with sharp, clean lines—perfect for names and numbers on the back of sports jerseys. A machine, like a Cricut or Silhouette, precisely cuts your design from a sheet of colored vinyl.

Once the excess vinyl is weeded away, the design is placed on the shirt and a heat press melts the adhesive, permanently bonding it to the fabric. The final result is a slightly raised, crisp graphic that really pops.

HTV is the perfect choice for:

- Simple text and logos: Think one-color logos for a small business or lettering for a custom gift.

- Small, personalized orders: Since you're not dealing with big setup costs for screens, it's incredibly cost-effective for one-off projects.

- A variety of fabrics: HTV works great on cotton, polyester, and even blended materials.

Plastisol Transfers: The Best of Both Worlds

Now, this is where things get interesting. Plastisol transfers are a clever hybrid, giving you the premium feel of screen printing with the on-demand flexibility of a heat press. Here’s how it works: your design is screen-printed with plastisol ink onto a special release paper, not directly onto a shirt.

These pre-printed sheets can then be stored for months. When an order comes in, you just grab a transfer, place it on the shirt, and use your heat press to apply it.

This “print now, press later” approach is a game-changer. It lets you get the high-quality, durable finish of screen printing without having to guess how many shirts you'll need in each size. You can get bulk pricing on the transfers and press them on different items as you go.

Imagine a local band orders 500 plastisol transfers of their logo. Instead of printing hundreds of shirts that might not sell, they can press them onto t-shirts, hoodies, or tote bags as they need them for shows. This strategy blends the quality of traditional printing methods for t shirts with the agility of modern, on-demand fulfillment, making it an incredibly smart move for any growing brand.

Dye Sublimation for All-Over Polyester Prints

Dye sublimation is where art and chemistry really come together. It's one of the most incredible printing methods out there, capable of creating jaw-dropping, permanent designs that have absolutely zero texture. You can't feel the print at all because the ink literally becomes part of the fabric.

Think about what happens to a block of dry ice. It doesn't melt into a puddle; it turns straight into a gas. Sublimation works on a similar principle. A special solid ink is heated until it vaporizes, and that gas then permanently bonds with polyester fibers. This process is how you get those super vibrant, all-over prints that will never crack, peel, or fade.

That chemical reaction is also what makes sublimation so picky about its materials. The process only works with synthetic fibers, making it the perfect match for 100% polyester shirts. It simply won't work on natural fibers like cotton because the ink can't form that critical molecular bond.

When Is Sublimation the Right Call?

Since the ink becomes one with the fabric, sublimation is the ideal choice for apparel that needs to stay breathable and feel completely smooth. It’s the undisputed champion for designs that need to cover a garment from seam to seam.

- Custom Activewear: This is the magic behind those cycling jerseys and yoga leggings with bold, all-over patterns that don’t affect the fabric's stretch or sweat-wicking properties.

- Photo-Realistic Shirts: Sublimation can reproduce photographs with breathtaking detail and an unlimited color palette, making it perfect for custom shirts with complex imagery.

- Seamless, All-Over Graphics: If you want a design that flows flawlessly over seams and across the entire shirt, this is the only way to go.

The real secret to dye sublimation is that it dyes the fabric's fibers directly. This isn't ink sitting on top of the material; it's a permanent infusion of color that leaves the print as soft and durable as the garment itself.

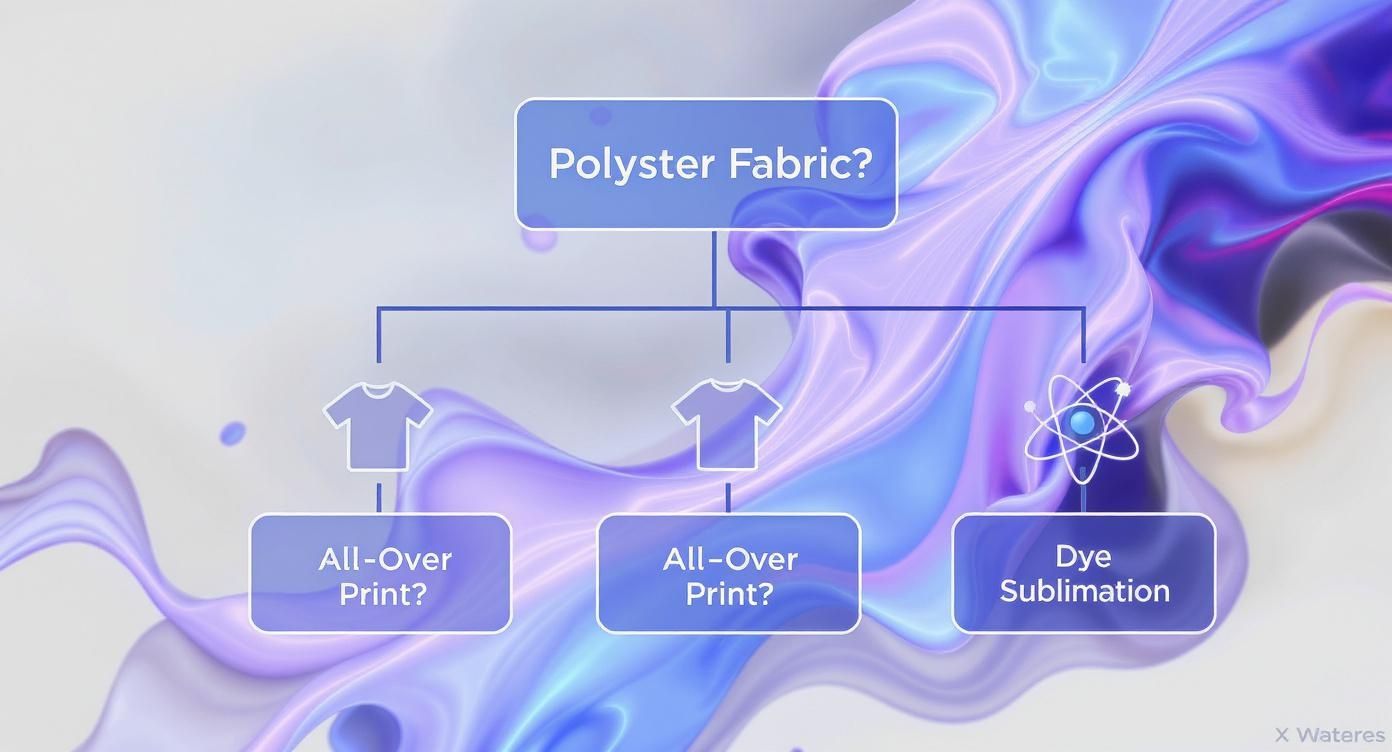

This handy decision tree can help you figure out if sublimation is the best route for your polyester project.

As you can see, if you're working with polyester and need a seamless, full-coverage design, dye sublimation is in a league of its own.

Key Limitations to Keep in Mind

The biggest catch, besides the fabric restriction, is color. Because the sublimation process adds dye into the fabric, it only shows up on white or very light-colored garments.

Trying to sublimate a design onto a black polyester shirt is like drawing on black paper with a yellow highlighter—the colors just won't be visible. To get a better handle on how these materials behave, check out the key differences between cotton vs polyester in our detailed guide.

When used in the right situation, though, sublimation creates absolutely stunning results that no other printing method can touch.

How to Select the Best Printing Method for Your Project

Choosing the right printing method for your t-shirts isn't about finding the single "best" option—it's about finding the best fit for your specific project. What works perfectly for a massive corporate event would be all wrong for a one-of-a-kind birthday gift.

Think of it this way: if you're outfitting a 500-person team with a simple, two-color company logo, screen printing is your workhorse. Its cost-per-shirt drops dramatically as the order size grows, making it a no-brainer for big batches. But if you want to print a single shirt with a detailed family photo, that same screen printing process would be wildly impractical. That’s where a method like Direct-to-Garment (DTG) printing comes in, handling complex, one-off designs with ease.

It all boils down to balancing four key ingredients: order size, the complexity of your design, your fabric choice, and of course, your budget.

Making the Final Decision

To cut through the noise, just ask yourself a few simple questions:

- How many shirts are you making? For anything over 25 pieces, screen printing almost always wins on price. For just one or a handful of shirts, DTG is your go-to.

- What does your artwork look like? If you have a full-color photograph or a design with gradients and intricate details, DTG and dye sublimation are your best friends. For bold, simple graphics with limited colors, screen printing and Heat Transfer Vinyl (HTV) are perfect.

- What fabric are you printing on? This is a big one. Dye sublimation only works its magic on polyester. DTG truly shines on 100% cotton. Heat transfers, on the other hand, are much more flexible and can work on a variety of materials.

One final, crucial tip: make sure your artwork is ready for prime time. A low-resolution file will look blurry and pixelated when printed, no matter how great the printing method is. You may need to increase the pixel count of a photo for clear results to guarantee a crisp, professional-looking final product.

The right method is the one that brings your vision to life without blowing your budget or sacrificing quality. Take a moment to weigh these factors, and you'll end up with a shirt you’re proud of.

To help visualize these trade-offs, we've put together a simple decision matrix.

T-Shirt Printing Method Decision Matrix

This table breaks down how each printing method stacks up across the most important factors. Use it as a quick reference guide to see which technique best aligns with your project's goals.

| Feature | Screen Printing | DTG Printing | Heat Transfer Vinyl | Dye Sublimation |

|---|---|---|---|---|

| Best For | Bulk orders (25+), simple designs | Single or small orders, complex photos | Names, numbers, simple logos | All-over prints, sportswear |

| Design Complexity | Best for 1-4 solid colors | Unlimited colors, photos, gradients | Best for simple shapes & text | Unlimited colors, photos, patterns |

| Feel on Shirt | A distinct layer of ink on the fabric | Soft, breathable, ink infused in fibers | A flexible vinyl layer on the fabric | No feel at all, part of the fabric |

| Fabric Type | Works on most fabrics, best on cotton | Best on 100% cotton, light colors | Works on cotton, poly, blends | 100% polyester only (white/light) |

| Durability | Very high, long-lasting | Good, can fade with many washes | Very high, can crack over time | Excellent, will not crack, peel, or fade |

| Cost | Low per-shirt on high volume | Moderate for one-offs, high for bulk | Moderate, depends on labor | Moderate to high |

Ultimately, this matrix highlights that there's a perfect tool for every job. Whether you need the volume and durability of screen printing or the photographic detail of DTG, understanding these differences is the key to a successful print run.

Your T-Shirt Printing Questions, Answered

Even after comparing all the options, you probably still have a few questions buzzing around. That's completely normal. Let's tackle some of the most common things people ask so you can lock in your decision with total confidence.

What’s the Most Durable T-Shirt Printing Method?

When you want a print that lasts, two methods are the clear front-runners: screen printing and dye sublimation. Screen printing lays down a thick, rugged layer of ink that cures right onto the fabric. It's built to last for years without much fuss.

Dye sublimation, however, is in a league of its own for permanence. The ink literally becomes one with the polyester fibers. This means the design won't crack, peel, or fade—ever. It will last as long as the shirt itself.

Which Printing Method Is Best for Just One Custom T-Shirt?

If you're making a single, one-of-a-kind shirt, Direct-to-Garment (DTG) is the way to go, hands down. Unlike screen printing, which has a hefty setup process, DTG has almost no prep time, making it super affordable for a single item.

Think of a DTG printer as a highly advanced inkjet printer, but for fabric. It can print a detailed, full-color photo onto a single shirt without the costly and time-consuming screen setup. This makes it perfect for a unique gift, a design prototype, or just a cool shirt for yourself.

Can You Print a Complex Photo on a Dark Shirt?

Yes, you definitely can! Both DTG and some high-quality plastisol transfers can produce stunning, full-color photographic prints on dark fabrics.

DTG is often the best tool for this specific job. The printer starts by laying down a white "underbase" layer. This acts like a bright white canvas on the dark shirt, making sure every color in your photo pops exactly as you intended. While screen printing can also do this, it's a complicated process involving multiple screens that gets expensive fast for just a few shirts.

Ready to bring your designs to life with professional, vibrant prints? Cobra DTF offers high-quality, American-made Direct-to-Film transfers that work on a huge variety of fabrics. Get started today and see the difference for yourself.