A Guide to DTF Printer Ink for Vibrant Prints

Share

DTF printer ink is the lifeblood of the Direct-to-Film process. It’s a specially formulated, water-based pigment ink designed to produce brilliant, tough, and stretchy designs on all sorts of fabrics. Whether you're working with cotton, polyester, or a tricky blend, this ink is the magic that makes the whole system work.

What Exactly Is DTF Printer Ink?

Think of DTF ink like the specialized fuel for a high-performance engine. You wouldn’t put regular gas in a race car, and you definitely can't use standard inkjet or DTG ink in a DTF printer. It just won’t work. DTF ink is a unique water-based pigment formula made for one job: printing onto a special transfer film, grabbing onto an adhesive powder, and then permanently fusing to fabric under heat and pressure.

This specific print-powder-press workflow is what makes DTF so versatile. To get a better feel for it, it helps to understand the detailed composition of printer ink and see how different formulas are built for different tasks. The recipe for DTF ink is carefully balanced for this exact process. If you want a full breakdown of how all the pieces fit together, our guide on what DTF printing is covers the entire A-to-Z.

The Core Components of DTF Ink

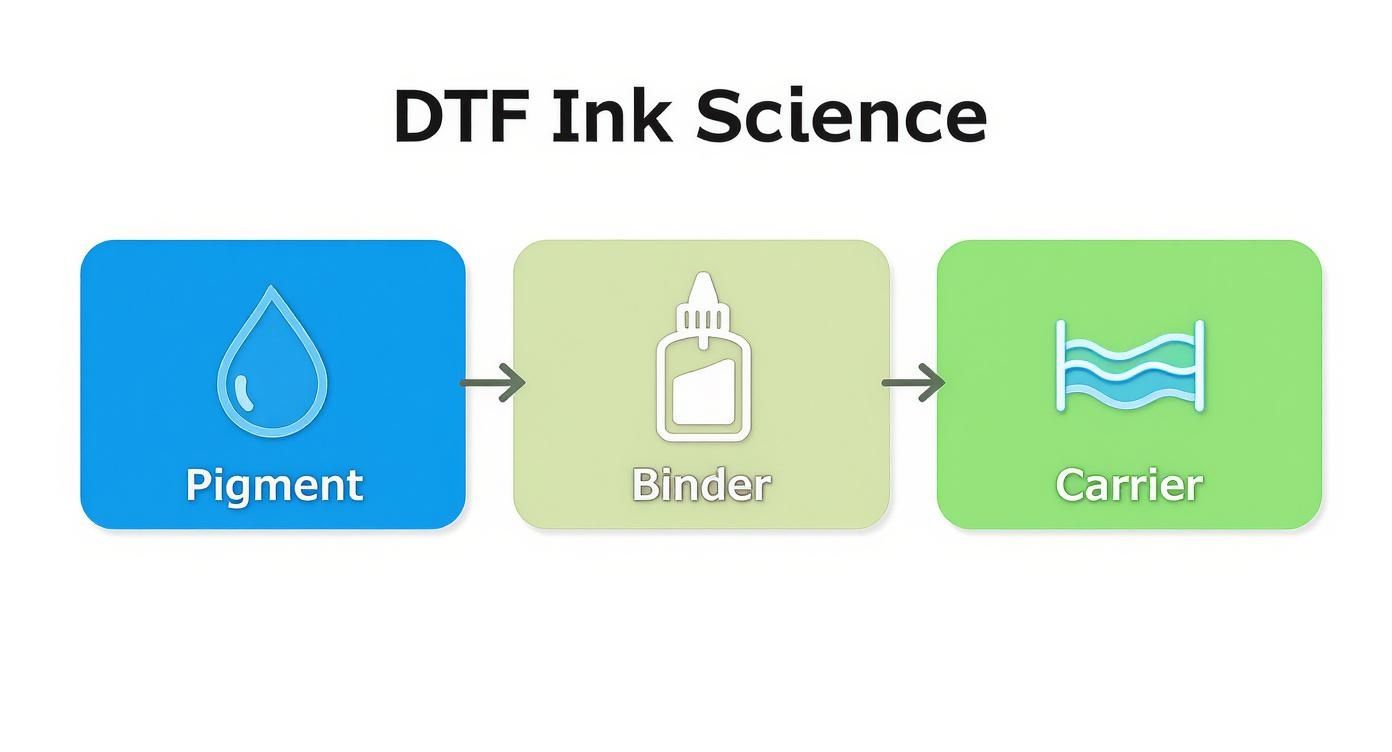

At its core, every drop of DTF ink is a cocktail of three key ingredients working together. Knowing what they are and what they do really helps clarify why this ink is so different and effective.

- Pigment: These are the tiny, solid particles that actually give the ink its color. For DTF, these particles have to be exceptionally fine so they don't clog the delicate printheads, but still pack enough punch to deliver rich, solid color.

- Binder: You can think of this as the "glue" in the ink. It’s a polymer that, once cured with heat, creates a strong, flexible bond with the fabric's fibers. This is what gives your final print its impressive durability and stretchiness.

- Carrier Solution: This is the liquid that carries the pigment and binder—mostly deionized water mixed with agents like glycols. It's what gives the ink the perfect viscosity to flow through the printer nozzles smoothly, without drying out mid-print or bleeding on the film.

When you mix these three things together, you get an ink that can lay down vibrant, stretchable, and wash-resistant prints on a massive range of materials. From 100% cotton to fussy polyesters, it handles them all without needing any fabric pre-treatment.

This unique chemistry is the secret sauce behind DTF's popularity with small businesses and custom apparel shops. It opens the door to creating complex, full-color designs on almost any garment you can think of, no matter if it's light or dark. In the end, the ink is the real hero of the DTF process, setting the foundation for every single transfer you produce.

The Science Behind High-Performance DTF Inks

To really get why premium DTF ink works so well, you have to look at its chemistry. The difference between a vibrant, long-lasting print and one that fades and cracks after a few washes almost always comes down to what’s inside the bottle. Every drop is a carefully engineered mix of three key things: pigment, binder, and a carrier solution.

Think of it like a high-tech recipe. The pigment is the main flavor (the color), the binder is what holds it all together, and the carrier solution is the liquid base that makes it pour smoothly. Get that balance wrong, and the whole thing is a mess.

The Three Pillars of DTF Ink Chemistry

First up is the pigment. These are microscopic solid particles that give the ink its color. In a quality DTF ink, these particles are milled down to an incredibly fine powder—often smaller than 100 nanometers—so they can flow through the tiny nozzles of your printhead without causing a clog. This isn't just about protecting your printer; it's also the secret to getting deep, rich colors on the film.

Next, you have the binder. You could argue this is the most critical part for durability. It’s essentially a heat-activated glue that just sits there until you press the transfer. When the heat hits, the binder melts and physically fuses the pigment to the fibers of the garment. A great binder results in a flexible, permanent bond that stretches with the fabric instead of cracking or peeling off in the wash.

Finally, there’s the carrier solution. This liquid base, usually made of deionized water and humectants like glycol, is what holds the pigment and binder in a stable suspension. It’s formulated to have the perfect consistency—not so thick that it clogs the printhead, but not so thin that it bleeds all over the film.

When manufacturers nail the balance between these three components, they create an ink that doesn't just produce amazing prints but also keeps your expensive equipment running smoothly. It’s why investing in a scientifically formulated ink pays off in reliability and consistency.

Why Technical Specs Matter

Beyond the basic ingredients, a few key technical properties determine how the ink actually behaves in your printer. These aren't just random numbers on a data sheet; they directly affect your day-to-day print quality.

- Viscosity: This is just a fancy word for the ink's thickness. If it’s too thick, it won't flow properly, leading to banding and missing lines in your print. If it’s too thin, it can drip or oversaturate the film, making your designs look blurry.

- Surface Tension: This controls how the ink droplets form and behave when they land on the transfer film. The right surface tension keeps the dots tight and uniform, giving you sharp, crisp images. The wrong tension causes "dot gain"—where the ink spreads out, muddying the details. You can see how this precision impacts the final result in our guide to creating DTF custom transfers.

- pH Level: The ink's acidity can affect your printer's internal parts. A well-made DTF ink has a neutral pH to prevent it from corroding the delicate metal components inside the printhead over time.

To make this easier to digest, here’s a quick breakdown of what to look for:

Key Technical Specifications of DTF Ink

This table outlines the ideal ranges for critical technical properties of DTF ink and explains why each specification matters for print quality and printer health.

| Technical Specification | Ideal Range | Impact on Performance |

|---|---|---|

| Viscosity | 3-6 cP | Ensures smooth flow through printheads without clogging (too high) or leaking (too low). |

| Particle Size | < 100 nm | Prevents nozzle blockages and ensures vibrant, even color distribution. |

| Surface Tension | 30-40 mN/m | Controls droplet formation for sharp lines and prevents ink from bleeding on the film. |

| pH Level | 7.0 - 9.0 | A near-neutral pH prevents corrosion of the internal metal parts of the printhead. |

Getting these technical details right is what allows DTF ink to deliver consistent, professional results.

This advanced chemistry is exactly what’s fueling the massive growth in the custom apparel world. In fact, the DTF printer ink market alone was valued at around USD 1.234 billion in 2025. This boom is all thanks to the demand for personalization and the constant scientific improvements making these inks better and more reliable.

How White Ink Unlocks Full-Color Potential on Any Garment

Printing vibrant, full-color designs on dark fabrics used to be a massive headache for apparel decorators. That all changed with the introduction of white DTF ink.

Think of it like painting a dark wall. If you slap bright yellow paint directly onto a navy blue surface, the result will be a murky, disappointing green. But if you put down a solid coat of white primer first? That yellow will pop exactly as you intended. White DTF ink acts as that essential primer for fabric. It lays down a brilliant, opaque base that makes the CMYK colors on top look stunningly vibrant, no matter the garment color.

This foundational layer is the secret behind DTF's incredible versatility. Whether you're printing on a black cotton hoodie, a royal blue polyester jersey, or a heather gray blend, that white ink base ensures your design looks just as bright and punchy as it does on your computer screen. It effectively creates a fresh white canvas right on the shirt, giving you consistent, high-fidelity color every single time.

The Underbase and Overprint Method

The real magic is in the layering process, which is all handled by your RIP (Raster Image Processing) software. First, the printer puts down the CMYK (Cyan, Magenta, Yellow, Black) colors onto the DTF film. Then, in a second pass, it lays a perfectly aligned layer of white ink directly on top of the color.

When you heat press the transfer onto a shirt, that order gets flipped. The white ink layer touches the fabric first, creating the solid base, and the CMYK layer sits on top, facing out. This "underbase" technique is what guarantees that even the softest pastels and brightest neons jump off the shirt with incredible intensity.

The entire job of white DTF ink is to create an opaque foundation. It physically blocks the garment's color from showing through, ensuring the final print is vibrant, accurate, and looks exactly how you designed it.

This infographic breaks down how the key ingredients in the ink—pigment, binder, and carrier—work together to make this happen.

Each part has a critical role, from the pigment that provides the color to the binder that makes sure your design lasts wash after wash.

Managing the Unique Challenge of White Ink

Here’s the catch: white ink isn't like the others. It has its own set of rules. The brilliant white comes from a pigment called titanium dioxide, which is much heavier and denser than the pigments used in CMYK inks. Think of it like trying to mix fine sand and water—if you let it sit, the sand is going to sink to the bottom. That’s exactly what happens with white ink.

This tendency to settle is why maintenance is absolutely non-negotiable. If those titanium dioxide particles fall out of suspension, they create a thick sludge that will clog your printer's dampers, ink lines, and, worst of all, the printhead. This leads to spotty prints, banding, or even expensive repairs. This is also where knowing the best shirts for DTF comes into play; a quality garment gives a well-maintained ink system the best possible surface to adhere to.

To fight against this settling, most modern DTF printers have a few tricks up their sleeves:

- White Ink Circulation Systems: Many pro-level printers have a system that constantly pumps the white ink through the lines, keeping those heavy pigments moving so they can't settle.

- Ink Cartridge Agitation: Other systems use a small motor to periodically shake or stir the white ink right in the cartridge or tank.

If your printer doesn’t have these automated features, the responsibility falls on you. It is absolutely essential to get in the habit of gently shaking your white ink cartridges every single day before you start printing. This simple, two-minute task re-suspends the pigment, guarantees a smooth and consistent flow, and protects your investment. Proper white ink management is the key to professional, reliable DTF printing.

Choosing the Right Ink for Your DTF Printer

Picking the right DTF ink is one of the most critical decisions you'll make for your printing business. This isn't just about finding the cheapest bottle on the shelf; it's a strategic move that directly impacts your printer's health, the quality of your final product, and your overall workflow.

Using the wrong ink is like putting diesel in a regular car. It might seem like fuel, but it's guaranteed to cause catastrophic, expensive damage down the road.

The idea of a "one-size-fits-all" DTF ink is a dangerous myth. The single most important factor is whether the ink's specific formula is compatible with your printer’s printhead. Different printheads, like the popular Epson i3200 and XP600 models, are built differently. They have unique nozzle sizes, firing mechanisms, and flow requirements, and they absolutely are not interchangeable.

An ink designed for a high-volume i3200 head has a different viscosity and pigment particle size than one made for a smaller XP600. Trying to force the wrong ink through a printhead is a recipe for disaster. You'll face constant clogging, infuriating banding in your prints, wonky colors, and could even permanently fry the most expensive part of your entire printer.

Matching Ink to Your Printhead

Think of your printhead as a finely-tuned, high-precision instrument. Its nozzles are microscopic, jetting out thousands of ink droplets every second. For everything to work perfectly, the ink has to flow through these tiny channels at just the right speed—no resistance, no dripping.

Here’s a closer look at why that printhead-ink relationship is so vital:

- Nozzle Size: Industrial heads like the i3200 have larger nozzles built for a higher volume of ink. They need an ink with a specific viscosity to keep up. If the ink is too thin, you'll get overspray and blurry prints. If it's too thick, the head will be starved for ink, leading to gaps and clogs.

- Viscosity Requirements: The XP600, which is common in many desktop DTF setups, uses much finer nozzles. It absolutely requires a thinner, lower-viscosity ink to work without being strained. Pushing a thick ink through an XP600 is a fast track to blockages and permanent damage.

Always, always confirm that a DTF ink is specifically formulated for your printer's exact printhead model. A good supplier will state compatibility clearly. Choosing the right formula is the best thing you can do to protect your investment and get predictable, high-quality results every time.

What to Look for in an Ink Supplier

Beyond the technical specs, your ink supplier is essentially your partner in production. A great one does more than just sell you bottles of liquid; they provide reliability, consistency, and peace of mind. Your business runs on a steady supply of quality materials, and any downtime from bad ink or shipping delays is money straight out of your pocket.

When you're checking out a new supplier, keep an eye out for these tell-tale signs of a trustworthy partner.

Key Supplier Qualities

- Rigorous Quality Control: Look for suppliers who manufacture their ink under strict quality control, ideally in the USA. This ensures you get the same color and performance from every single batch, saving you the headache of constantly re-profiling your machine.

- Superior Wash Fastness: The durability of the final print is what keeps customers coming back. Top-tier inks have fantastic wash ratings, meaning colors stay bright and the print feels great without cracking, even after dozens of washes.

- Reliable and Fast Shipping: You can't print if your ink bottles are empty. A supplier with fast, dependable shipping is a lifeline that prevents production from grinding to a halt. Check for clear shipping policies and quick turnaround times.

- Accessible Expert Support: When you hit a snag—and you will—you need real answers from people who actually know the gear. A supplier with a knowledgeable and easy-to-reach support team can help you troubleshoot issues in minutes, not days.

Taking the time to choose your DTF ink carefully is a foundational step for building a successful printing business. By matching the ink to your printhead and finding a supplier you can count on, you're setting yourself up for consistent quality, happy customers, and long-term success.

Essential Maintenance for Your DTF Ink System

Think of your DTF printer as the engine of your apparel business. That makes the ink system its fuel line. And just like any high-performance machine, it needs consistent care to keep it from breaking down at the worst possible moment.

Proper maintenance isn't just about cleaning up messes. It's about being proactive. A good routine is what guarantees those vibrant, sellable prints, cuts down on expensive downtime, and ultimately protects the investment you've made in your equipment.

If you let things slide, you're practically asking for clogged printheads, inconsistent colors, and a pile of wasted shirts and film. The good news is, turning a few key tasks into daily habits will keep your printer running like a champ.

Your Daily Maintenance Checklist

Don't skip these. Seriously. These quick, five-minute tasks are your first line of defense against the most common (and most frustrating) DTF ink problems, especially those caused by that tricky white ink.

- Gently Shake the White Ink: Before you even think about printing, give your white ink cartridges or tanks a gentle shake. The heavy titanium dioxide pigments in white ink love to settle overnight. A quick agitation gets everything back in suspension, ensuring a smooth, consistent flow and preventing that dreaded sludgy buildup.

- Perform a Nozzle Check: Run a nozzle check pattern first thing in the morning. Think of it as a quick health report for your printhead. It will instantly show you if any nozzles are blocked. Catching a tiny clog early and running a simple head cleaning cycle is a thousand times easier than dealing with a major blockage later on.

Weekly and Monthly Deep Cleaning

While those daily checks are critical, you'll also need to do some more thorough cleaning to handle the gunk that builds up over time. These tasks focus on keeping the most important parts of your ink system free of dried ink and lint, which are the main culprits behind poor print quality.

A solid weekly deep clean prevents minor headaches from turning into major repair bills.

Proper maintenance is the cheapest insurance you can buy for your DTF printer. A few minutes of preventative care each week can save you hundreds, if not thousands, of dollars in replacement parts and lost business.

To keep your machine in top shape, you need a routine. Sticking to a schedule like the one below will prevent most ink-related issues before they even start.

DTF Printer Ink Maintenance Schedule

| Frequency | Task | Purpose |

|---|---|---|

| Daily | Shake White Ink & Run Nozzle Check | Prevents white pigment settling and identifies clogs before they worsen. |

| Weekly | Manually Clean Printhead & Wiper | Removes stubborn ink residue and fibers that automated cleanings miss. |

| Weekly | Wipe the Capping Station | Ensures a perfect seal to prevent the printhead from drying out when idle. |

| Monthly | Flush the Waste Ink Line | Prevents blockages in the waste system that can cause ink to back up. |

Following this checklist is the best way to ensure consistent performance and protect the most expensive parts of your printer, like the printhead.

Troubleshooting Common DTF Ink Issues

Even with the best maintenance habits, things can still go wrong. The key is knowing how to diagnose and fix problems quickly to minimize frustration and wasted materials.

-

Problem: Stubborn Clogs

If a standard head cleaning cycle doesn't fix a missing nozzle, you’ve got a more stubborn clog on your hands. This usually happens if the printer sits idle for too long.- Solution: Try running a more powerful cleaning cycle, as recommended by your printer’s manufacturer. If that doesn't work, you can carefully use a foam cleaning swab with a dedicated DTF printhead cleaning solution to gently wipe the head's surface. Never use force or press hard.

-

Problem: Color Inaccuracy

Are your prints suddenly looking faded, or are the colors just off? This could be caused by a few different things.- Solution: First, the obvious: check that you haven't run out of a specific color. Next, run a nozzle check—a clog in just one color channel can throw off the entire color mix. Finally, double-check your RIP software settings to make sure nothing was changed by accident.

Getting a Handle on Ink Costs and Your Shop's Footprint

Let’s get down to brass tacks. The technical side of DTF is fascinating, but a successful print shop lives and dies by its numbers and its commitment to responsible practices. For anyone running a DTF printer ink setup, that means nailing two things: your cost per print and your shop’s environmental and safety protocols. Get these right, and you're building a business that's not just profitable, but sustainable for the long haul.

Figuring out your true ink cost for each job is probably one of the most critical numbers you can track. It’s the bedrock of your pricing strategy, letting you quote jobs with confidence and truly understand your return on investment. If you don't know this number, you're flying blind—you might be making sales, but are you actually making money?

Thankfully, you don't have to guess. A good RIP software is your best friend here, giving you a shockingly accurate estimate of how much ink a design will use, often broken down by individual colors. This lets you see exactly how much CMYK and white ink you'll need for a graphic before the printer even starts whirring.

Gauging Your True Cost Per Print

So, how do you calculate it? You just need a few pieces of the puzzle:

- Ink Cost: What you pay per liter (or milliliter) for each color. Don't forget, white ink is its own beast and usually costs more, so track it separately.

- Ink Usage per Print: Your RIP software will spit this number out in milliliters (mL).

- Other Consumables: Every print also uses film and powder, so be sure to factor in the cost of those materials.

The Simple Math: A straightforward way to look at it is: (CMYK ink cost + White ink cost) + Film Cost + Powder Cost = Total Print Cost. Once you have this total, you can price your finished products knowing exactly what your profit margin is on every single item that goes out the door.

This kind of financial clarity is non-negotiable in a market that's blowing up. The global DTF printing market was valued at a whopping USD 2.72 billion in 2024 and is on track to hit USD 3.92 billion by 2030. That's a lot of competition. Knowing your costs inside and out is what will keep you competitive. You can dig deeper into the direct-to-film printing market's growth to see just how fast this space is moving.

Safety and Environmental Best Practices

Running a print shop isn't just about the prints; it's about the people making them. You have a responsibility to create a safe work environment, and while modern DTF printer ink is formulated to be user-friendly, you should never skip basic safety steps.

First up, ventilation. This is an absolute must. When you're curing the adhesive powder, it can release fumes. A well-ventilated room or, even better, a dedicated fume extractor is essential to keep the air clean. And of course, always use your Personal Protective Equipment (PPE). Gloves are a no-brainer to keep ink off your skin, and safety glasses will save you from any accidental splashes.

Understanding Certifications like OEKO-TEX

Want to stand out to customers who care about what they wear? Third-party certifications are your secret weapon, and the big one in the textile world is OEKO-TEX.

When you see that a DTF ink is OEKO-TEX certified, it means it’s been independently tested and proven to be free from a whole laundry list of harmful chemicals. For your customers, this is a signal that the final printed shirt is safe for direct skin contact. This is a massive selling point, especially for anyone making children's clothing or working with brands that have a green mission. Using certified inks isn't just good practice—it's a powerful marketing tool.

Got Questions About DTF Ink? We've Got Answers.

When you're diving into Direct-to-Film printing, you're bound to have questions. It's a technical process, and getting a handle on the details—especially the ink—can save you a world of headaches, time, and wasted materials. Let's clear up some of the most common questions we hear from printers.

What's the Deal with Shaking White Ink?

This is probably the single most important question. The white DTF ink is the workhorse of the operation, but its chemistry is a bit different. It uses titanium dioxide for its brilliant opacity, and those pigment particles are heavy.

If left to sit, even overnight, they will settle at the bottom of the cartridge. This is a fast track to stubborn clogs and printhead damage.

Pro Tip: Make it a non-negotiable part of your daily startup routine. Before you print anything, gently shake your white ink bottle or cartridge every single day. This simple, 10-second habit is the best insurance policy you have for protecting your printhead.

Can I Mix and Match Different Inks?

It's tempting to think "ink is ink," but in the world of digital printing, that couldn't be further from the truth. A frequent question is whether you can use DTG (Direct-to-Garment) ink in a DTF printer.

The answer is an emphatic no. They are formulated for completely different jobs. DTG ink is designed to soak into and dye fabric fibers directly. DTF ink, on the other hand, is engineered to sit on top of a transfer film and then bond to the garment with an adhesive.

Trying to use the wrong kind will, at best, result in prints that won't stick. At worst, you could cause catastrophic and permanent damage to your printer's delicate ink system. Stick with ink made specifically for your DTF printer model.

Other Common Ink Questions

- How long does DTF ink last? Unopened bottles are typically good for about one year. Once you've opened a bottle, it's best to use it within six months to avoid any issues with pigment settling or changes in viscosity.

- Why are my prints cracking or fading after washing? This almost always points to one of two culprits. It's either a low-quality ink with a weak binder, or your curing process is off. Double-check that your heat press temperature and time are set correctly for your specific powder and ink.

If you're looking for high-quality, USA-made DTF ink that you can count on for brilliant, durable results, check out the selection at Cobra DTF. We provide the consistency your business needs with fast, reliable shipping. Shop for reliable DTF ink at CobraDTF.com