What is DTF Transfer? Discover the Printing Method Today

Share

A Direct-to-Film (DTF) transfer is a modern way to get a vibrant, full-color design onto a special clear film, which you then heat-press onto just about any fabric. The easiest way to think of it is like a high-tech, super-flexible sticker for clothes and other items. It delivers incredible detail and works on materials that other printing methods struggle with, like polyester, cotton, leather, and blends of any color.

Your Quick Guide to DTF Transfers

So, what's really going on with a DTF transfer? At its heart, it’s an incredibly versatile and powerful way to take a digital image from your computer and put it onto a physical product with seriously impressive results. Unlike older methods that print directly onto a shirt (like Direct-to-Garment) or require complicated screen setups, DTF printing creates the design on a separate transfer film first.

That intermediate step is what makes it so flexible. By printing onto the film, dusting it with an adhesive powder, and then curing it, you end up with a ready-to-press transfer that can be applied to a massive range of products.

This process gives you a few major wins:

- Fabric Freedom: You're no longer stuck with just cotton or light-colored polyester. DTF plays nicely on dark garments, synthetics, and even tricky items that other methods can't touch.

- Vibrant and Detailed Prints: The technique allows for photorealistic quality. It handles fine lines and complex color gradients beautifully, something that's often a headache with other printing styles.

- Durability and Feel: The finished print is soft, stretchable, and really holds up against cracking or fading. In many cases, the print will outlast the garment itself.

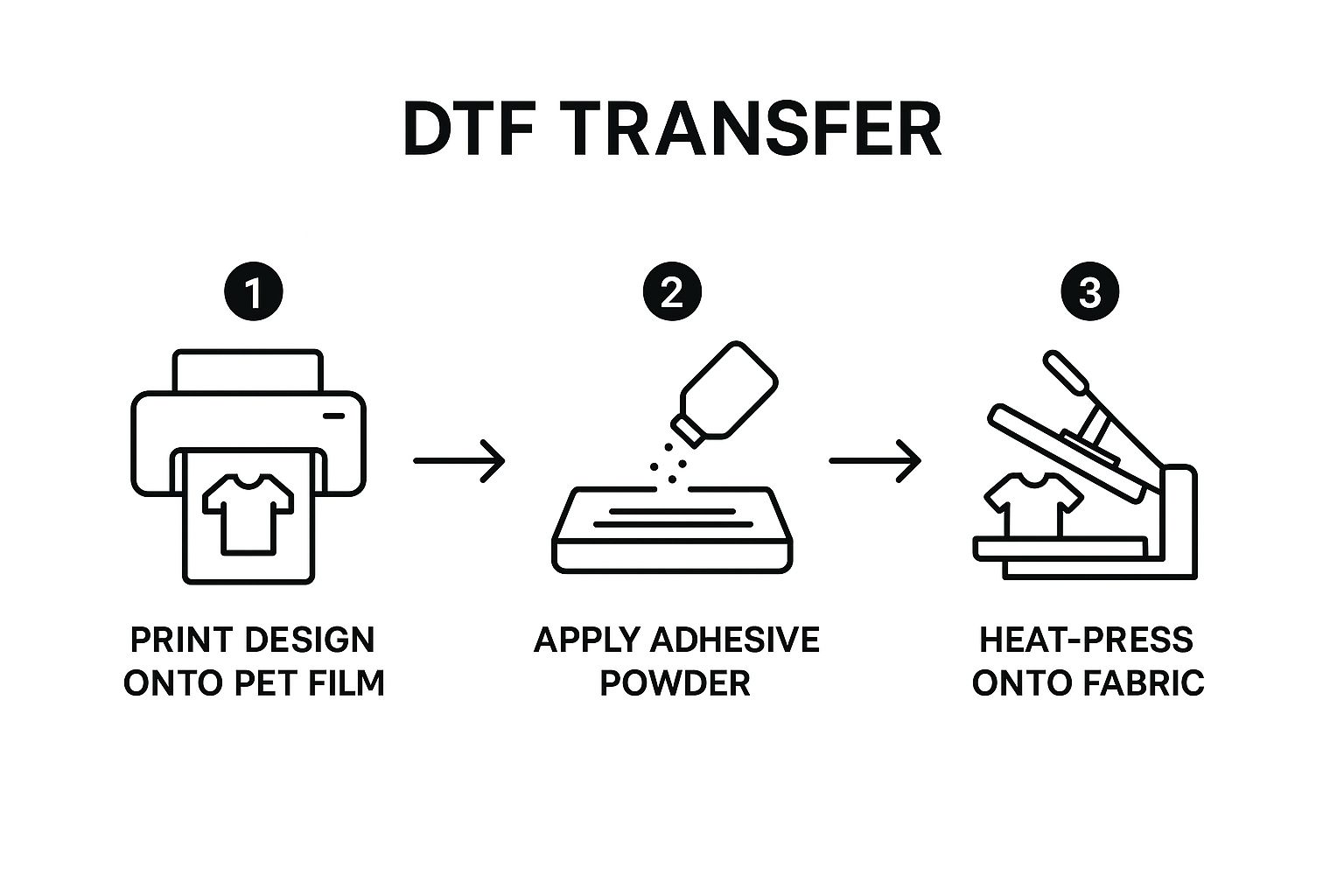

This infographic breaks down how a design gets from a digital file to a finished transfer.

As you can see, it’s a straightforward process that ensures you get consistent results from the first print to the final press. To really get a handle on how these stages fit together, let’s break down the essential gear and materials you need.

The Core Components of DTF Technology

Here's a quick look at the essential materials and their functions in the DTF transfer process.

| Component | Its Role in the Process |

|---|---|

| DTF Printer & Inks | This is a specialized inkjet printer that uses CMYK and white inks to print the design onto the transfer film. |

| PET Transfer Film | A special coated film that acts as the carrier for the ink and adhesive before it's moved to the final fabric. |

| Adhesive Powder | This is the magic "glue"—a fine thermoplastic powder that sticks to the wet ink on the film. |

| Heat Press | You'll use this twice: first to melt the powder and cure the transfer, and then again to press the final design onto the item. |

Each of these components has a specific job to do. When they all work together correctly, you get a durable, high-quality print every single time.

How a DTF Transfer Is Made and Applied

So, how does a digital file on a computer screen become a vibrant, wearable design? Let's pull back the curtain on the DTF process. This isn't just a simple print-and-press job; it's a specific sequence of steps where each one sets the stage for the next, turning a graphic into a durable and flexible image you can apply to almost anything.

The whole journey, from file to finished shirt, can be boiled down to five key stages.

The Five Stages of DTF Transfer Creation

1. Printing on PET Film

Everything starts with a special DTF printer. Instead of printing directly onto a shirt, your design is printed onto a sheet of PET (polyethylene terephthalate) film. This clear film is just the carrier. The printer first lays down all the colors (CMYK) and then puts down a layer of white ink on top. This white layer is what makes the design pop, especially on dark fabrics.

2. Applying the Adhesive Powder

While the ink is still wet, the magic happens. A fine, white thermoplastic adhesive powder is sprinkled over the entire design. It’s like dusting a cake with powdered sugar, but way more important. The powder only sticks to the wet ink, and any extra is shaken off, leaving a perfectly coated graphic.

Why is this powder so important?

Think of this powder as the super glue that will bond your design to the fabric. Without it, the ink would have nothing holding it onto the garment. This step is absolutely critical for creating a print that lasts.

3. Curing the Transfer

Next, the powdered film goes through a curing process. It's heated in a special oven or hovered under a heat press, which melts the powder. The heat transforms the grainy powder into a smooth, even layer of adhesive that completely seals the ink.

Once it cools, you have a finished, ready-to-press DTF transfer. This is exactly what you get when you order from a supplier. For a deeper dive into working with these, check out our guide on custom DTF transfers ready to press.

Applying the Transfer to a Garment

4. The First Heat Press

Now for the fun part. The finished transfer is placed on the garment, design-side down. A heat press clamps down with firm pressure and high heat for about 15-20 seconds. This heat reactivates that melted adhesive, causing it to bond deep into the fibers of the fabric.

5. The Cold Peel and Final Press

Patience is key here. After the first press, you let the garment cool down completely. Once it's cool to the touch, you can gently peel back the PET film, and your design is left behind, permanently fused to the fabric.

To finish it off, many pros do a quick final press for a few seconds. This helps lock everything in, improves wash durability, and gives the print a nice matte finish.

This whole methodical process has come a long way. DTF printing first emerged in the early 2000s as a more flexible and affordable printing method. By combining PET film, specialized inks, and hot-melt powder, it opened the door to putting full-color prints on fabrics that were tough for older methods to handle.

Why Creatives and Businesses Are All-In on DTF

The buzz around DTF printing isn't just about a new gadget; it’s about a technology that genuinely solves problems for everyone from Etsy creators to large-scale apparel brands. People are switching to DTF because it hits the sweet spot between flexibility, quality, and cost. It effectively tears down the creative walls that used to make custom apparel a complicated and expensive headache.

Think about what it would mean to never have to turn down a customer's unique request again. That's the real power of DTF transfers. They give you the freedom to print on a massive range of materials without needing a different setup for every single one.

Print on Almost Anything

One of the biggest draws is simply how versatile DTF is. Other printing methods can be incredibly picky about fabrics, but DTF is the "one-size-fits-all" solution the industry has been waiting for.

- Cotton and Blends: It handles 100% cotton, 50/50 blends, and tri-blends—the bread and butter of the t-shirt world—without breaking a sweat.

- Polyester and Synthetics: DTF really excels on slick materials like polyester and nylon, making it perfect for athletic wear, team jerseys, and jackets.

- Way Beyond T-Shirts: The possibilities don't stop there. You can press designs onto leather patches, canvas tote bags, hats, and even denim, opening up a whole new world of products to offer.

This kind of freedom simplifies your entire workflow. One printing method can handle nearly any job that walks in the door, letting you expand your catalog with confidence.

A Feel and Durability That Lasts

The quality of the final product is where DTF really pulls ahead of the pack. Forget those old-school transfers that felt like a stiff, plastic sticker. A well-pressed DTF transfer is soft, thin, and feels like it’s part of the fabric. It even stretches with the garment, so you don't have to worry about the design cracking or peeling after a few trips through the laundry.

When done right, a quality DTF transfer can survive 50 or more washes, often looking great long after the shirt itself has worn out. This is the kind of reliability that builds a reputation for quality.

This incredible durability makes DTF a solid choice for just about anything, from high-end fashion pieces to heavy-duty workwear. The print is built to last.

Gorgeous Graphics Without Breaking the Bank

For designers, DTF is a game-changer. It can reproduce photorealistic images, fine lines, and subtle color gradients with breathtaking clarity. Thanks to the white ink base layer, colors stay bright and true on any fabric, whether it’s a stark white tee or a jet-black hoodie.

From a business standpoint, it just makes sense. For small to medium-sized batches, DTF is often cheaper than screen printing, which demands costly screen setups for every single color. It also skips the messy pre-treatment step required for DTG printing, which saves both time and money. This combination gives businesses the financial breathing room to experiment with new designs without having to invest in a huge inventory upfront.

How DTF Transfers Stack Up Against Other Methods

To really get why DTF transfers are such a big deal, you have to see how they compare to the other heavyweights in the custom apparel world. For a long time, Direct-to-Garment (DTG) and old-school screen printing were the only real options. But now, DTF is shaking things up by offering a killer combination of versatility, quality, and affordability that solves the biggest problems of both older methods.

Knowing the pros and cons here is key to picking the right tool for the job. Whether you're a small shop knocking out custom orders or a brand figuring out how to produce a new line, your best choice will come down to the fabric you're using, how complex your designs are, and what your budget looks like.

DTF vs. Direct-to-Garment (DTG) Printing

On the surface, DTF and DTG look a lot alike. Both are digital, so they’re fantastic for detailed, full-color designs. The real difference, though, is how the ink gets onto the shirt.

DTG printers work kind of like your office paper printer, applying ink directly onto the fabric. This process requires a messy pre-treatment spray and really only works well on 100% cotton materials.

DTF takes a totally different route. It prints the design onto a special film first, and then you heat-press that film onto the garment. This simple two-step process gets rid of pre-treatment altogether and lets you print on just about anything—polyester, cotton, leather, blends, and fabrics of any color.

For a deeper dive into the nitty-gritty, check out our complete DTF vs DTG printing guide.

DTF vs. Screen Printing

Screen printing is the OG workhorse of the t-shirt industry, famous for its incredible durability and bright, punchy colors. It works by pushing ink through a mesh stencil (a screen) onto the fabric. This method is amazing for huge batches of simple designs, but the catch is that every single color needs its own custom screen, which gets expensive and time-consuming fast.

This is where DTF shines for today's creators.

- Design Freedom: DTF can print photorealistic images with millions of colors at no extra setup cost. With screen printing, a complex, multi-color graphic becomes a massive, costly headache.

- Small Batches Welcome: Screen printing really only makes sense for large runs (think 50+ pieces) because of the high setup fees. DTF, on the other hand, is perfect for one-offs, small orders, and printing on demand.

- A Softer Touch: A thick screen print can feel heavy and stiff on a shirt. A DTF transfer is much thinner, softer, and more flexible, which makes the final product a lot more comfortable to wear.

DTF essentially bridges the gap between DTG's full-color, high-detail capabilities and screen printing's ability to print on almost anything. It gives you the best of both worlds: vibrant, detailed prints that can go on nearly any fabric, without the crazy setup costs or material roadblocks.

DTF vs DTG vs Screen Printing at a Glance

To make your decision easier, here is a side-by-side comparison of the top printing methods. This quick-reference table should help you see exactly where each method shines and guide you toward the best fit for your projects.

| Feature | DTF Transfer | DTG Printing | Screen Printing |

|---|---|---|---|

| Best For | Small-to-medium batches, complex multi-color designs, diverse fabrics. | Full-color photos on 100% cotton, one-offs, and small orders. | Large batches (50+) with simple designs and few colors. |

| Fabric Compatibility | Excellent. Works on cotton, polyester, blends, leather, nylon, and more. | Limited. Best on 100% cotton; struggles with synthetics. | Very good. Works on most fabrics but ink may vary. |

| Color Complexity | Unlimited colors and gradients with no extra cost. | Unlimited colors and gradients with no extra cost. | Limited. Each color requires a new screen, increasing cost. |

| Feel on Garment | Soft, lightweight, and flexible. Almost like a thin layer of vinyl. | Very soft and breathable as ink soaks into the fabric. | Can be thick and heavy, especially with many colors. |

| Durability | High. Very resistant to cracking and fading with proper care. | Good. Can fade over time with repeated washing. | Excellent. Extremely durable and long-lasting. |

| Setup Cost | Low. No per-design setup fees. | Low. No per-design setup fees. | High. Significant costs for screen creation. |

This adaptability is exactly why DTF printing is quickly becoming the go-to choice in so many corners of the industry. It's an accessible technology that delivers professional results, which is a game-changer for businesses big and small.

Real-World Uses for DTF Printing

Okay, enough with the technical stuff. Let's talk about what DTF transfers are actually doing out in the wild. The real magic of this technology isn't in the process itself, but in how it turns ordinary items into custom works of art or seriously tough branded gear. From small Etsy shops to massive production runs, DTF is making new product ideas possible.

The proof is in the numbers. The global market for direct-to-film printing was valued at USD 2.72 billion and is expected to climb to USD 3.92 billion by 2030. That kind of growth tells you this isn't just a trend; it's a fundamental shift driven by the demand for affordable, high-quality custom products.

Durable Workwear and Team Apparel

One of the most practical and impressive uses for DTF printing is on workwear. Think about it: materials like polyester and nylon are notoriously tricky to print on, but they're the backbone of most uniforms and safety gear. DTF solves that problem beautifully.

Because the adhesive bonds so well to synthetics, DTF is the go-to for items that have to survive a lot of abuse.

- Construction Vests: Crisp, vibrant company logos that stay put on high-vis fabrics.

- Team Jerseys: Names, numbers, and sponsor logos that stretch with the fabric and won't crack under pressure.

- Corporate Uniforms: Sharp, professional logos on polo shirts and jackets that hold up wash after wash.

The print’s flexibility and resistance to fading make it a truly reliable choice for gear that gets put through the wringer every single day.

And this isn't just for fabric anymore. A really cool offshoot of this technology is UV DTF printing, which lets you apply the same kind of vibrant, durable designs to hard goods like mugs, phone cases, and even wood. Check out our complete guide on UV DTF printing to see how that works.

Custom Fashion and Merchandise

For artists, designers, and clothing brands, DTF printing is a game-changer. It unlocks the ability to create complex, full-color designs on all sorts of apparel that used to be a huge headache—or just plain expensive—to decorate.

Imagine detailed, multi-color artwork on a denim jacket, a photorealistic portrait on a black hoodie, or a finely detailed logo on a canvas tote bag. DTF makes all of this achievable without the steep setup costs and color limitations of traditional screen printing.

This flexibility is a huge win for online stores. For any brand using DTF to create custom products, building a smart ecommerce content strategy is key to showing off what's possible and attracting customers.

We're even seeing DTF used on things like sneakers and backpacks, giving designers total freedom to bring their wildest ideas to life on almost any surface imaginable.

Common Questions About DTF Transfers

As you start looking into DTF, you'll naturally have some questions. It's a newer technology, and getting straight answers is key to figuring out if it's the right fit for your projects. Let's walk through some of the most common things people ask about how these transfers last, how they feel, and what it actually takes to make them.

Getting a handle on these details will show you exactly why so many creators and print shops are making the switch.

How Long Do DTF Transfers Last?

This is usually the first question on everyone's mind, and for good reason—nobody wants a design that cracks after a few washes. The simple answer is that DTF transfers are built to last. When you press them correctly with a good heat press, you can expect a transfer to hold up for 50 to 100 washes, often outlasting the t-shirt itself.

How? It all comes down to the thermoplastic adhesive. When you press the transfer, this adhesive melts and forms a rock-solid bond with the fibers of the fabric. The inks themselves are also super flexible, so they stretch with the material instead of cracking and peeling like older, more rigid types of transfers.

Pro Tip for Longevity: To get the absolute most life out of a DTF print, tell your customers to wash the garment inside-out in cold water. Tumble drying on low is fine, but for best results, hang it up to dry. That's the secret to keeping it looking brand new.

Following these simple care instructions ensures the print stays sharp and securely fused to the fabric for years to come.

What Does a DTF Print Feel Like on a Shirt?

The "hand feel" is a huge deal, especially if you're selling retail-quality clothing where comfort is everything. A properly applied DTF transfer feels surprisingly soft and lightweight. It's a night-and-day difference from those thick, plastic-feeling heat transfers from the past, and it's even softer than many multi-layered screen prints.

You can tell the design is there, of course, but it's thin and integrates right into the fabric, stretching and moving with it. This means the shirt stays comfortable and doesn't feel like it has a stiff patch on it. This premium feel is a major reason why DTF has become the go-to for fashion brands that care just as much about comfort as they do about looks.

Do I Need a Special Printer for DTF?

Yes, if you plan on making the transfers yourself from scratch, you need a dedicated DTF setup. You can't just use your standard office inkjet or laser printer. The whole process relies on a specific set of equipment working together to create a press-ready transfer.

Here’s the gear you'd need to get into DTF production:

- A Specialized DTF Printer: This is a modified inkjet printer built to handle PET film and run both CMYK and white DTF inks.

- DTF Inks: These are pigment-based inks formulated specifically for flexibility and durability on fabric.

- PET Transfer Film: A special coated film that holds the ink and powder until you're ready to press.

- Adhesive Powder: This fine, white powder is the "glue" (a thermoplastic polyurethane, or TPU) that bonds the print to the garment.

- A Curing Station: You need a way to melt the powder onto the ink, which usually means a small conveyor dryer, a curing oven, or a heat press that can hover without touching.

- A Heat Press: The non-negotiable final piece for actually applying the finished transfer to your item.

Given the investment, many businesses—especially when they're just starting out—choose to buy pre-made transfers from a supplier instead of buying all the equipment.

Is DTF Printing Better Than Sublimation?

This is a classic comparison, but one isn't "better" than the other. They're just different tools for different jobs. The best choice comes down to what you're printing on and what you want to achieve.

-

Sublimation is a fantastic process where the ink turns into a gas and permanently dyes the fibers of polyester fabric. The result is a print with zero feel—it literally becomes part of the material. The catch? It only works on high-polyester-count fabrics (ideally 100%) and light-colored garments.

-

DTF printing, on the other hand, is the master of versatility. It works by laying the design on top of the fabric, which means you can print on almost anything: cotton, polyester, leather, blends, you name it. And thanks to its white ink underbase, the colors pop on fabrics of any color, including black.

So, when should you use each? Go with sublimation for performance gear, team jerseys, and any polyester items where you want that no-feel finish. For pretty much everything else, especially cotton t-shirts and dark garments, DTF is the more flexible and capable solution.

Ready to see the quality and versatility of DTF for yourself? At Cobra DTF, we provide premium, American-made transfers that are vibrant, durable, and ready to press. Skip the equipment investment and get perfect prints delivered to your door in 1-3 days.

Explore our custom DTF transfers and elevate your projects today.