A Guide to T Shirt Printing Techniques

Share

So you want to print a custom t-shirt. Sounds simple enough, right? Well, getting that design from your screen onto the fabric is where the real magic—and the important decisions—happen. The printing method you choose is the single most critical factor that will define how your shirt looks, feels, and holds up over time.

This guide is your inside look at the most popular t-shirt printing techniques. We'll break down how each one works, what it's good for, and where it falls short. Think of me as your seasoned guide to the print shop floor.

Your Guide to T-Shirt Printing Techniques

Creating custom tees is an art and a science. It’s not just about slapping a logo on a shirt; it’s about picking a process that truly brings your vision to life. The technique you land on will affect everything from the texture of the print to how vibrant it looks after its tenth trip through the laundry.

A touring band, for example, needs merch that can survive a mosh pit and hundreds of washes. That calls for a completely different approach than the one-off tees a tech startup might order for a single event.

It’s this demand for unique, personalized apparel that has exploded the custom printing world into a massive industry. We're talking about a global market that hit around $8.17 billion, and it's not slowing down. People want custom, and this trend is driving serious growth. You can see the full breakdown of the custom t-shirt printing market growth on globenewswire.com.

What You Will Learn

To help you choose with confidence, we're going to walk through the main players in the custom apparel game. I'll give you a solid overview of the core methods and what makes each one tick, setting you up to really understand the nitty-gritty details we'll cover later.

You’ll get a clear handle on:

- Screen Printing: The undisputed king for big batches with bold, vibrant designs.

- Direct-to-Garment (DTG): The perfect solution for intricate, full-color images, especially on small orders.

- Heat Transfers: A whole family of methods, including vinyl, that offers incredible versatility.

Getting these fundamentals down is everything. It’s the difference between a final product you’re proud of and a costly mistake. Your goal, your budget, and your design should all point you to the right choice.

Without this baseline knowledge, you could end up picking a method that’s way too expensive for a large run or one that turns your detailed artwork into a blurry mess. My goal here is to give you the practical, real-world knowledge you need to pick the perfect t-shirt printing technique for any project you can dream up.

Screen Printing: The Timeless Workhorse

When you picture classic t-shirt printing, chances are you're thinking of screen printing. Also known as silk screening, this method is the industry's tried-and-true champion, famous for its incredible durability and rich, vibrant colors. It's a hands-on process that’s been perfected over decades, making it the go-to for big projects.

The easiest way to get your head around screen printing is to think of it like a very precise stenciling process. Every single color in your design needs its own dedicated screen—a fine mesh pulled tight over a frame. A squeegee then pushes ink through the open parts of that mesh stencil and onto the shirt, laying down one color at a time.

This layer-by-layer method is what gives screen-printed shirts their distinct, bold feel. The ink isn't just sitting on the surface; it's physically pressed into the fabric, creating a bond that’s tough enough to handle years of washing.

How The Process Unfolds

Screen printing is a methodical craft. It's a blend of artistry and technical know-how that, when done right, produces thousands of perfectly consistent shirts.

Here’s a quick look at the steps involved:

- Design Separation: First, the artwork is broken down into its individual colors. A design with red, white, and blue becomes three separate, single-color images.

- Screen Creation: A unique screen is made for each of those colors. The mesh is coated with a light-sensitive emulsion, and the design is essentially "burned" into it with UV light, creating a custom stencil.

- Ink Application: The t-shirt is laid flat on a press, and the first screen is carefully aligned. A thick ink (usually plastisol) is pulled across the screen with a squeegee, forcing it through the stencil and onto the fabric.

- Curing the Print: Once all the colors are applied, the shirt takes a trip through a large conveyor dryer. The heat cures the ink, locking it permanently into the fabric fibers. This is the secret to its legendary durability.

This multi-step setup is why screen printing has a higher upfront cost. Making all those screens takes time and effort. But once they’re ready? You can print shirt after shirt incredibly quickly and efficiently.

The real magic of screen printing lies in its economies of scale. While the setup for a 10-shirt order might seem expensive, the cost per shirt drops dramatically when you’re printing 500. This makes it the undisputed king for large-scale production.

When to Choose Screen Printing

So, is screen printing the right choice for you? It all boils down to the specifics of your project. It's a powerhouse for certain jobs but not the best tool for others.

This should be your first choice when:

- You Need a Large Volume: For any order of 50 or more identical shirts, screen printing is almost always the most budget-friendly path. It's the standard for company uniforms, band merch, and event giveaways.

- Your Design is Simple and Bold: It absolutely shines with designs that have a handful of solid colors (usually up to 5). Think strong logos, crisp text, and graphic illustrations, not photographs.

- Durability Is Your Top Priority: Nothing else really compares for longevity. Screen-printed graphics hold up against cracking, fading, and peeling, which is why they’re perfect for workwear or anything that will see a lot of use.

On the flip side, it's not a great fit if you just need one custom shirt or your design is full of complex color gradients and photorealistic details. The cost and labor of creating multiple screens for a single print just doesn't make sense—that's where other methods come in.

2. Direct-to-Garment: The Digital Artist

If screen printing is the tried-and-true workhorse of the industry, then Direct-to-Garment (DTG) is the modern digital artist. The name says it all. A specialized printer sprays water-based inks directly onto the fabric, working almost exactly like the inkjet printer you have in your office, just on a t-shirt instead of paper. No screens, no messy layers of ink—just a clean, precise application of color.

This process unlocks a level of detail that other methods just can't touch. Imagine trying to print a high-resolution photograph, complete with all its subtle shadows, smooth gradients, and millions of colors. DTG handles that kind of complexity without breaking a sweat, making it the go-to for photorealistic images and incredibly intricate graphics.

Because the ink is sprayed right onto the garment, it soaks into the cotton fibers instead of sitting on top like a thick, plastic-y layer. The result is a print that feels remarkably soft and breathable, almost like it's part of the shirt itself. It's an incredibly comfortable way to wear a custom design.

The Power of Digital Precision

The real magic of DTG is its digital-first approach, which completely sidesteps the long setup process of screen printing. You don't have to separate colors or burn individual screens for every part of your design. You just load the digital file, pop the shirt in the printer, and hit "print."

This efficiency totally changes the game for small-scale projects. It gives individuals and businesses the freedom to create one-of-a-kind pieces without having to order a massive batch just to make it affordable.

With DTG printing, the complexity of a design has zero impact on the cost. A design with two colors costs exactly the same to print as one with two thousand. This gives you complete creative freedom to print whatever you can dream up.

This freedom has definitely caught on. Digital printing is one of the fastest-growing t-shirt printing techniques out there. In fact, the demand for intricate, artistic designs is projected to grow at a CAGR of 12.1%. It’s clear that people want the high-quality, detailed prints that only DTG can deliver. You can dig deeper into the growth of the custom t-shirt market over on Grandviewresearch.com.

When DTG Is Your Best Choice

Knowing when to use DTG is all about playing to its strengths. It's not a one-size-fits-all solution, but for certain jobs, it’s simply unbeatable.

You should choose DTG printing when your project involves:

- Complex, Full-Color Designs: If your artwork is a photograph, a detailed illustration, or has subtle color fades, DTG is the only way to capture that nuance perfectly.

- Small Order Quantities: Just need one shirt for a birthday gift or a dozen for your startup team? DTG's lack of setup fees makes it the most budget-friendly option for small runs.

- Print-on-Demand Services: This technique is the engine that powers the entire print-on-demand business model, letting e-commerce shops sell unique designs without ever touching inventory.

- A Soft Feel Is a Must: For premium fashion apparel or any shirt where a soft, breathable print is non-negotiable, DTG's ink-soaking method feels far superior to thicker transfers.

However, DTG isn't without its weak spots. The process is slower on a per-shirt basis, which means it gets expensive for large runs compared to screen printing. DTG printers also work best on 100% cotton fabrics, as the natural fibers are great at absorbing the water-based inks. While you can print on some cotton blends, the results can be a bit hit-or-miss. It’s a crucial difference to keep in mind, as you'll see when comparing different methods—our guide on DTF vs DTG printing breaks this down even further.

Heat Transfer Methods: From Vinyl to Custom Transfers

Beyond printing ink directly onto a shirt, there's a whole family of popular t shirt printing techniques that fall under the "heat transfer" umbrella. If you've ever used an iron-on patch, you already get the basic idea. This is just the professional, high-tech version of that, using a combination of heat and pressure to apply a pre-made design right onto a garment.

This whole approach is a huge favorite for hobbyists, small businesses, and anyone needing personalized gear like team jerseys. It's a really accessible way to get into custom apparel without the steep learning curve of screen printing or the big investment in a DTG machine.

The world of heat transfer really breaks down into two main paths: Heat Transfer Vinyl (HTV) for those bold, solid graphics, and Printable Heat Transfers for creating full-color images.

The Power of Heat Transfer Vinyl

Heat Transfer Vinyl (HTV) is pretty much what it sounds like—a special vinyl material made specifically for fabric. A plotter, which is basically a computer-guided cutting machine, slices your design (like text or a logo) out of a solid-colored sheet of this vinyl. From there, you have to "weed" away all the excess vinyl by hand, leaving just your design on a sticky carrier sheet.

You then place that carrier sheet onto the t-shirt, put it in a heat press, and clamp it down. The combination of intense heat and firm pressure activates the adhesive on the vinyl's backing, bonding it permanently to the fabric.

- Best Use Case: HTV is the absolute king for personalizing team sportswear. That crisp, clean finish is perfect for putting player names and numbers on the back of jerseys. It's also fantastic for simple, one or two-color logos.

- Durability and Feel: The final result is a durable design that sits slightly raised on the shirt with super sharp edges. Good quality HTV is surprisingly long-lasting and flexible, though it will feel a bit thicker than methods where the ink soaks directly into the fibers.

Creating with Printable Heat Transfers

Printable heat transfers open the door to full-color designs without needing a fancy DTG printer. Instead of cutting your design from a sheet of colored vinyl, you actually print it onto a special transfer paper using a regular inkjet or laser printer.

After printing, the process feels a lot like HTV. You place the printed design onto the garment and press it with heat. It’s a straightforward way to get complex, multi-color images, and even photographs, onto a shirt. If you want to explore this further, this guide on heat transfer shirt printing offers a much more detailed look at the whole process.

The main trade-off with printable transfers is the feel on the shirt. The design sits on top of the fabric as a distinct layer, which can sometimes have a heavier, almost plastic-like texture. With enough time and washing, this layer is more likely to crack or peel than prints from other methods.

This makes it a great choice for promotional giveaways, one-off event shirts, or personal projects where top-tier longevity isn't the number one goal. It's a super cost-effective way to get vibrant, detailed images on a small scale.

Weighing the Pros and Cons

Heat transfer methods have a unique mix of benefits and drawbacks. Knowing when to use them is key to getting the results you want.

Advantages of Heat Transfer:

- Cost-Effective for Small Batches: With no screens to set up, it's incredibly affordable for one-off prints or tiny orders.

- Fabric Versatility: Unlike DTG printing, heat transfers work on a huge range of fabrics, from cotton and polyester to all sorts of blends.

- Vibrant, Bold Graphics: HTV, especially, delivers incredibly vivid and opaque colors that really pop on any color shirt.

Disadvantages of Heat Transfer:

- Heavier Feel: The design sits on the surface of the fabric, which can feel less breathable and thicker than a DTG or screen print.

- Potential for Cracking: Lower-quality transfers can be prone to cracking or peeling after you’ve washed and worn them a bunch.

- Time-Consuming for Bulk Orders: The manual process of cutting, weeding, and pressing each shirt one by one just isn't efficient for large production runs.

Direct to Film: The Modern Hybrid Solution

Ever wish you could take the stunning, full-color detail of DTG printing and apply it to literally any fabric? Well, that's pretty much what Direct to Film (DTF) brings to the table. It’s a newer technique that has absolutely taken the custom apparel world by storm, acting as a powerful middle-ground between different printing methods.

Think of it as a clever two-step process. First, your design is printed onto a special sheet of transfer film. Then, a powdered adhesive is applied to the back of the print and melted. That film is then placed on your garment, and a heat press works its magic, permanently bonding the vibrant design to the fabric.

This simple but brilliant workaround means you get the best of both worlds: gorgeous, photorealistic prints with the freedom to put them on almost anything.

The Ultimate in Fabric Versatility

If there's one thing that makes DTF a superstar, it's this: unmatched adaptability. DTG printing gets picky and really only loves cotton. But DTF? It plays well with almost everything, which is a massive win for any print shop dealing with diverse orders.

DTF is a fantastic choice for printing on:

- Cotton and Cotton Blends: It delivers crisp, opaque designs on light and dark cottons alike.

- Polyester and Performance Wear: This is where DTF really shines. It sticks beautifully to synthetic fabrics, making it the go-to for jerseys and athletic gear.

- Specialty Materials: You can even press DTF transfers onto trickier surfaces like leather, nylon, and canvas. This opens up a whole world of custom hats, bags, and unique accessories.

Think of DTF as the universal adapter for your designs. It lets you use the exact same print for a soft cotton hoodie, a sleek polyester jersey, and even a rugged canvas tote bag, keeping a brand’s look perfectly consistent across totally different products.

This kind of flexibility is a game-changer for production. You don't need a separate setup for your cotton jobs and another for your poly jobs. DTF handles it all. On top of that, the final print feels surprisingly soft and stretchy, and it holds up incredibly well against cracking and fading in the wash.

How DTF Stacks Up

So, when should you reach for DTF? This t shirt printing technique is the perfect problem-solver, stepping in right where other methods tap out. It masterfully blends print quality, fabric freedom, and efficiency.

It's the clear winner when you need vibrant, multi-color graphics on something other than 100% cotton. Let's say a local business wants its intricate logo on cotton polos for the office staff and on polyester jackets for an upcoming trade show. DTF is the answer—it ensures the logo looks identical on both, no compromises needed.

While the print has a slightly more noticeable feel on the shirt compared to DTG (but it's often much softer than old-school vinyl), its performance is tough to beat. For anyone needing high-quality, full-color prints on just about any textile you can think of, this modern hybrid is quickly becoming the default choice.

How to Select the Right Printing Technique

Choosing the perfect T-shirt printing technique can feel like a tough call, but it really just boils down to a few key details about your project. Think of it like picking the right tool for a job—you wouldn't use a sledgehammer to hang a picture frame. The right method is what makes sure your final shirt looks, feels, and holds up exactly how you envisioned it.

This decision is more important than ever. With e-commerce booming and younger buyers wanting unique gear, the demand for custom apparel is through the roof. Millennials and Gen Z are looking for clothes that show off their personality, whether it's a company logo or a niche pop culture reference. You can see just how much this is shaping the industry by checking out these custom T-shirt market drivers on coherentmarketinsights.com.

To nail your project, you just need to get clear on your goals first.

Key Questions for Your Project

Before you lock in a printing method, take a minute to think through these factors. Your answers will pretty much guide you straight to the best choice.

-

What Is Your Order Size?

Are you printing 500 shirts for a big company event, or just a single tee for a friend's birthday? For large batches, the sheer efficiency of screen printing almost always makes it the most economical option. But for small runs or one-offs, DTG and DTF are your go-to methods since they have almost no setup costs. -

How Complex Is Your Design?

If your artwork is a super-detailed photograph with tons of colors and smooth gradients, DTG is the undisputed champion. It handles that level of detail flawlessly. But for bold, simple graphics with just a handful of solid colors—like a classic sports team logo—screen printing or even heat transfer vinyl will give you that sharp, vibrant finish you're looking for. -

What Fabric Are You Printing On?

This one is a big deal and often non-negotiable. Some techniques are picky about materials. For instance, DTG printing works best on 100% cotton. Sublimation, on the other hand, is made exclusively for polyester. If you need something that can handle almost anything you throw at it—cotton, poly-blends, and even some synthetics—DTF is the clear winner for versatility. If you're unsure about fabrics, our guide on cotton vs polyester can help clear things up. -

What Is Your Budget and Deadline?

Let's be real—money and time matter. Screen printing involves more setup, so it has higher initial costs, but the price per shirt drops dramatically on large orders. DTG and DTF are fantastic for quick turnarounds on smaller, time-sensitive projects without a hefty upfront investment.

There’s no single “best” method for every situation. Your project's unique mix of order size, design complexity, fabric, and budget will point you to the perfect printing solution for your specific needs.

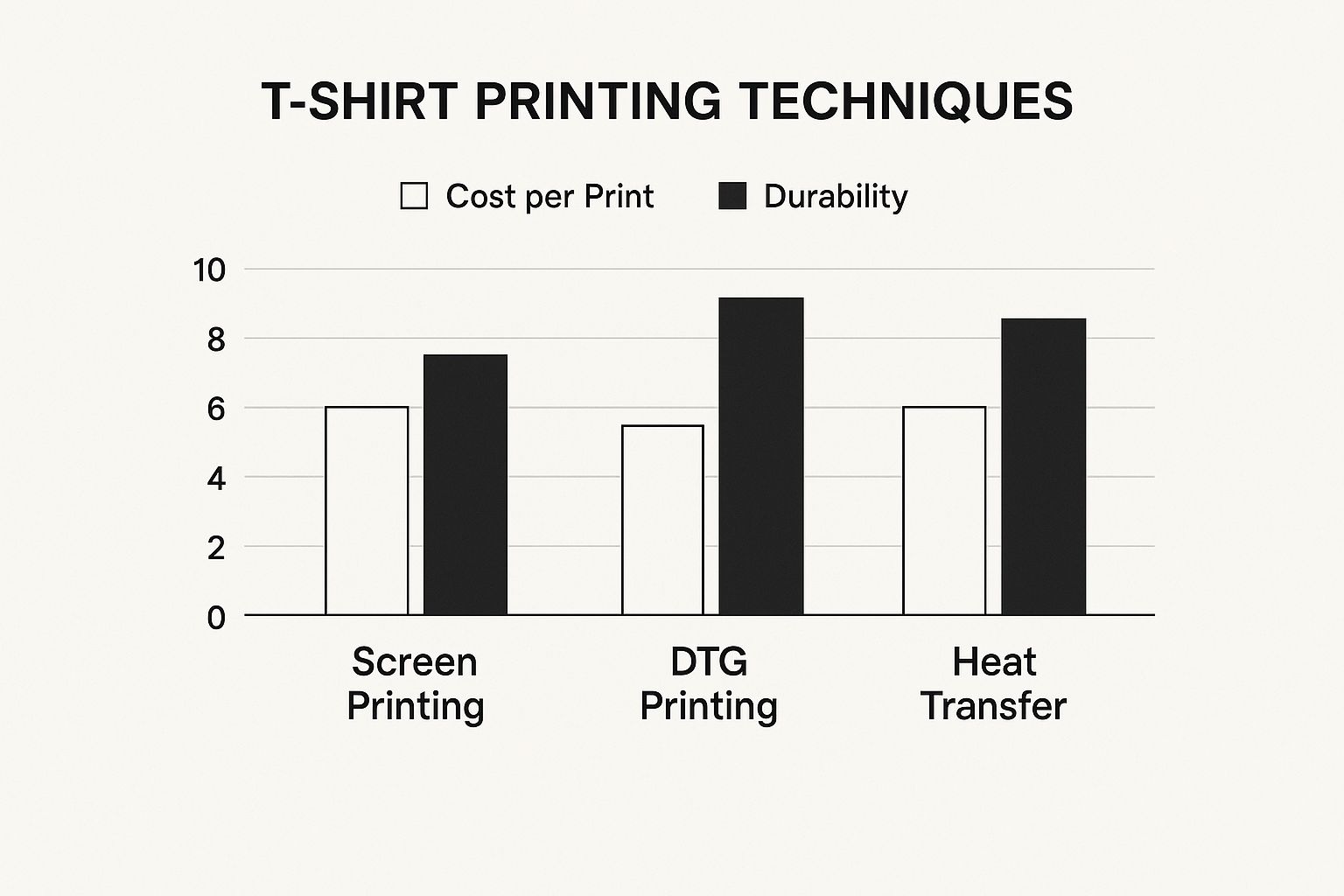

To help you see how these methods stack up, the infographic below gives a great visual breakdown of how cost and durability compare across the most popular options.

As you can see, screen printing really shines with its top-tier durability and lower costs on bulk orders. Meanwhile, DTG is a great, budget-friendly choice for one-off prints, even if the print isn't quite as rugged in the long run.

T-Shirt Printing Techniques Comparison

To make things even clearer, here’s a side-by-side look at the most common T-shirt printing methods. This table breaks down the key factors to help you match your project's needs with the right technology.

| Technique | Best For | Durability | Feel on Fabric | Color Complexity | Fabric Compatibility |

|---|---|---|---|---|---|

| Screen Printing | Bulk orders (50+), simple designs with few colors | Excellent (50+ washes) | Slightly thick layer of ink on top of fabric | Limited colors, not ideal for gradients | Versatile (cotton, blends, polyester) |

| DTG | Small batches, photorealistic designs, one-offs | Good (25-50 washes) | Very soft, ink soaks into fabric | Unlimited colors and gradients | Best on 100% cotton |

| Heat Transfer | Small orders, names/numbers, simple graphics | Moderate (20-30 washes) | Can feel like a plastic layer on the shirt | Varies; vinyl is simple, transfers can be complex | Cotton, polyester, and blends |

| DTF | All order sizes, complex designs, various fabrics | Excellent (50+ washes) | Soft and flexible, but sits on top of fabric | Unlimited colors and gradients | The most versatile (cotton, poly, leather, etc.) |

| Sublimation | Full-color, all-over prints on light-colored fabric | Permanent (lasts as long as the garment) | No feel at all, ink becomes part of the fabric | Unlimited colors, vibrant and permanent | 100% Polyester only |

This comparison should give you a solid starting point. By understanding the strengths and weaknesses of each method, you can confidently choose the one that will bring your creative vision to life perfectly.

Got Questions? We've Got Answers

Stepping into the world of custom t-shirts can feel a little overwhelming with all the different methods out there. To make things easier, I've rounded up some of the questions I hear most often from people just like you. Let's clear up any confusion so you can get started on your project with confidence.

What's the Most Durable T-Shirt Printing Technique?

When you need a print that will last through thick and thin, screen printing is the undisputed champion. The ink actually cures and locks into the fabric, creating a bond that can handle dozens and dozens of washes without giving up. That’s why it's the go-to for work uniforms, band merch, and anything that needs to be seriously tough.

Right on its heels, you'll find Direct to Film (DTF). DTF transfers are impressively tough and flexible, which makes them a fantastic alternative for long-lasting prints, especially on fabrics like polyester that screen printing can sometimes find tricky.

Which Printing Method Is Best for Photos on Shirts?

If you’re looking to print a detailed photo or a design with tons of colors and smooth gradients, Direct-to-Garment (DTG) is your best bet, hands down. Imagine an inkjet printer, but for t-shirts—that's DTG. It can reproduce millions of colors with incredible accuracy, giving you a sharp, vibrant image that looks just like the original.

The ink soaks right into the cotton, so the print doesn't feel heavy or plastic-y. It’s soft, breathable, and perfect for turning photos into wearable art or creating one-of-a-kind gifts on 100% cotton shirts.

The Bottom Line: For realistic photos and a soft feel on cotton, go with DTG. If pure, rugged durability across a wide range of fabrics is your main goal, screen printing and DTF are your strongest options. It's all about finding the right balance between the look you want and how long you need it to last.

What's the Most Affordable Option for a Small Batch of Shirts?

Just need a few shirts? Say, anywhere from 1 to 10? You’ll want a method that doesn’t have high setup fees. Your most wallet-friendly choices are:

- DTG Printing: Since there are no screens to prepare, printing one shirt with a complex design costs the same per-shirt as printing ten.

- DTF Transfers: Much like DTG, you can print a single transfer without any major upfront cost, giving you tons of flexibility.

- Heat Transfer Vinyl (HTV): Perfect for simple text or one-color logos. HTV is a super economical way to make a handful of custom pieces.

These methods skip the costly and time-intensive setup that screen printing requires. This makes them ideal for personal projects, trying out a new design idea, or making a few unique gifts without spending a fortune.

Ready to create stunning, durable designs that work on pretty much any fabric? At Cobra DTF, we're all about high-quality, American-made DTF transfers that deliver incredible results every single time. Check out our official Cobra DTF website to see how you can get faster turnarounds for your next apparel project.