A Guide to Made in USA Suppliers

Share

Opting for made-in-USA suppliers isn't just about patriotism; it's a sharp business move. In today's unpredictable global market, companies are realizing the immense value of supply chain resilience, quick turnarounds, and having a tight grip on product quality.

Why Businesses Are Turning Back to American Suppliers

The big push to source domestically is a direct reaction to the chaos we've seen on the global stage recently. For a long time, heading overseas for manufacturing felt like the only way to save a buck, but that approach has shown some serious cracks.

Businesses are now rethinking what "cost" really means. It's not just about the price per unit anymore. It's about the total cost, which includes the price of unexpected delays, frustrating communication barriers, and the risk that comes with a complex supply chain you can't see.

This shift is all about building a business that's more nimble and dependable. Instead of biting your nails waiting weeks or even months for a shipment to clear customs, you can get what you need in a matter of days. That kind of speed lets you jump on market trends and avoids tying up cash in massive, dusty inventories.

The New Economic Reality

This move toward domestic sourcing isn't just a trend; it's been kicked into high gear by real economic pressures. A perfect storm of new tariffs and geopolitical shake-ups has made importing goods both more expensive and a whole lot less predictable.

This forced many companies to look for local alternatives just to stay afloat. As a result, the demand for American-made products has skyrocketed, making domestic sourcing a smart, practical strategy for any business that wants to survive and grow. You can explore more about how tariffs ignited this demand for American-made goods and see the numbers for yourself.

"The whole game has changed. Businesses aren't just chasing the absolute lowest price anymore. They're investing in things that actually matter: reliability, speed, and transparency. A dependable local partner is worth far more than a slightly cheaper product that's stuck on a ship halfway across the world."

Key Drivers for Onshoring

This renewed focus on made-in-USA suppliers comes down to a few clear-cut advantages that directly boost a company's bottom line and operational health.

-

Supply Chain Resilience: A short, domestic supply chain is simply less exposed to international conflicts, shipping nightmares, and foreign port shutdowns. It’s a buffer against global chaos.

-

Enhanced Quality Control: Being closer to your supplier makes everything easier. You can actually visit the facility, collaborate on getting the product specs just right, and sort out any manufacturing hiccups almost instantly.

-

Faster Speed-to-Market: When lead times shrink from months to weeks—or even days—you can get new products out the door and restock your bestsellers before the competition knows what hit them.

-

Consumer Trust: Let's be honest, the "Made in USA" label is still a huge selling point. It tells customers they're getting a quality product made with ethical labor while supporting the local economy. That's a powerful message.

The Real Payoffs of Sourcing Domestically

Choosing to partner with Made in USA suppliers is about so much more than a tagline on your products. It's a strategic business decision that brings tangible benefits, sharpening your competitive edge and strengthening your entire operation from the ground up.

The most obvious win? Speed. Instead of playing the waiting game for weeks or even months as your products sail across an ocean and navigate customs, domestic sourcing shrinks that timeline down to just a few days. This incredible agility means you can jump on new trends, restock a hot-selling item instantly, and get your designs into customers' hands faster than anyone relying on a slow, overseas supply chain.

Then there's the hands-on quality control. When your supplier is closer to home, you can easily resolve issues as they happen, visit the facility to see that standards are being met, and work together on getting the details just right. This direct oversight is a game-changer, slashing the risk of defects and ensuring what you get is exactly what you envisioned.

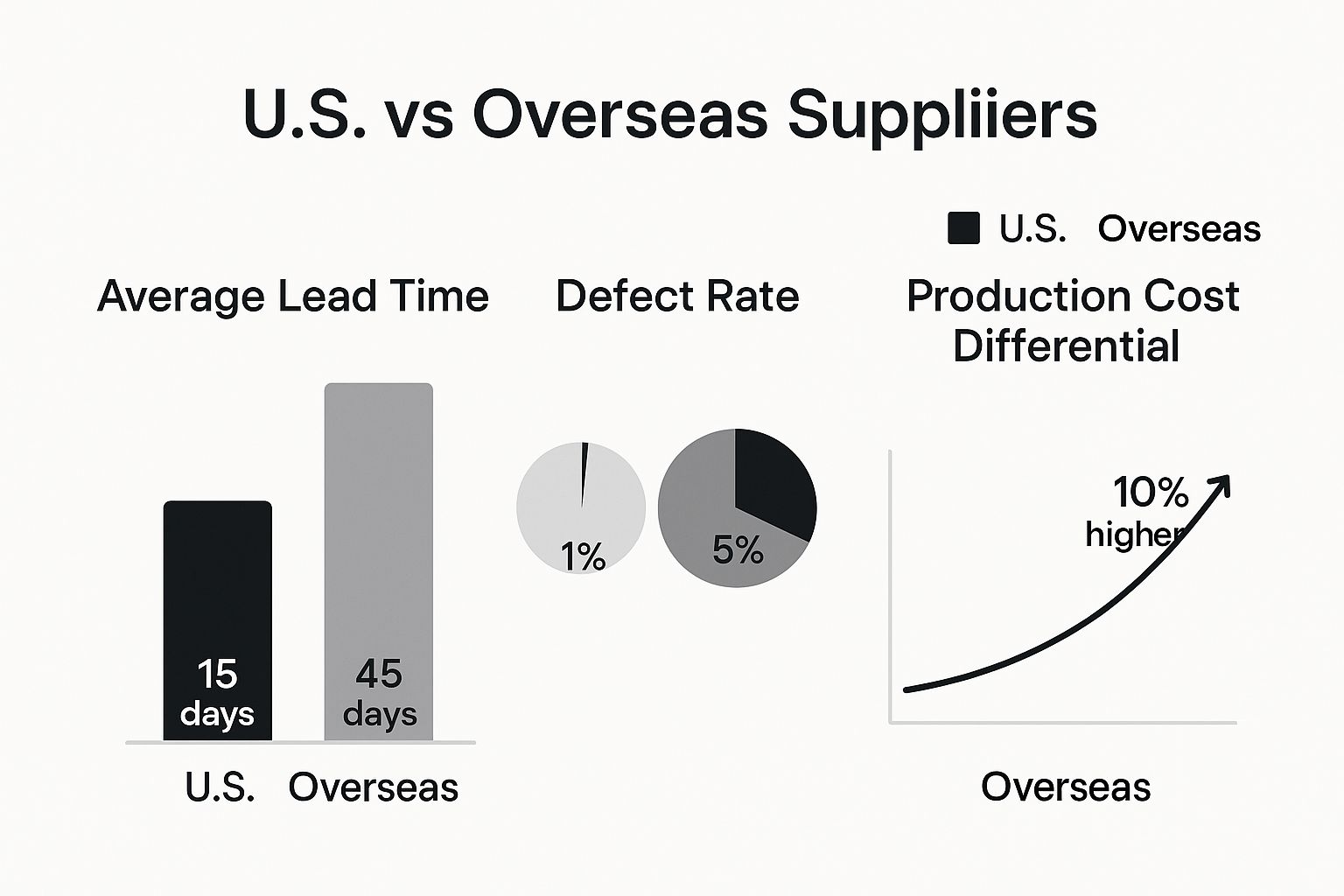

This visual gives a great at-a-glance comparison of the operational realities.

As you can see, a slightly higher unit cost is often a smart trade-off for dramatically lower defect rates and lightning-fast turnaround, giving you a much better overall value.

Comparing Domestic vs Overseas Sourcing

Making the right sourcing decision comes down to weighing the pros and cons of each approach. The following table breaks down the key differences between sticking with domestic partners and going overseas.

| Factor | Made in USA Suppliers | Overseas Suppliers |

|---|---|---|

| Speed & Lead Time | Much faster (days vs. weeks) | Significantly longer (weeks to months) |

| Shipping Costs | Lower and more predictable | High and subject to volatility |

| Quality Control | Easier to manage and verify | More challenging; requires remote oversight |

| Communication | Real-time, same time zone | Often delayed due to time differences |

| Regulatory Compliance | Simpler, shared legal framework | Complex; involves tariffs and import laws |

| Brand Perception | Strong "Made in USA" appeal | Varies; can be associated with lower quality |

Ultimately, the choice depends on your priorities. If speed, quality, and brand trust are at the top of your list, the advantages of a U.S.-based partner are hard to ignore.

A Boost for Your Brand and the Economy

Sourcing here at home delivers a powerful one-two punch for your marketing and the broader economy. For many shoppers, the "Made in USA" label is a powerful symbol of quality and trustworthiness, which can instantly elevate your brand and even justify a higher price. It tells a story of quality craftsmanship and a commitment to ethical production.

When you source domestically, you're doing more than just buying a product—you're investing in your own community's ecosystem. That decision supports local jobs, strengthens towns and cities, and contributes to a healthier national economy.

This isn't just a feel-good story; it has a massive economic impact. U.S. manufacturing is a powerhouse, contributing around $2.9 trillion to the GDP in just the first quarter of a recent year. With manufactured goods exports climbing to $1.6 trillion annually, these suppliers are absolutely essential for America's economic health and its standing on the global stage.

Making Your Operations Simpler

Working with domestic suppliers just makes life easier. It cuts through the complexity and friction that often comes with managing an international supply chain.

-

Simplified Compliance: You’re operating under the same set of rules. There's no need to become an expert on complicated import laws, surprise tariffs, or international trade disputes that could bring your business to a halt.

-

Effortless Communication: Being in the same time zone means you can pick up the phone and get an answer. Gone are the days of late-night calls and waiting 24 hours for an email reply. Clear, instant communication prevents costly mistakes and keeps your projects on track.

-

Stronger Partnerships: It’s just easier to build a real relationship with someone you can visit. That proximity helps build trust and encourages true collaboration, turning a simple supplier transaction into a genuine strategic partnership.

For more tips on building a solid foundation for your business, check out our collection of in-depth guides for apparel businesses.

How to Find and Vet the Right US Supplier

Okay, so you’ve decided to look for made in usa suppliers. That’s the easy part. The real work is sifting through that initial list to find a single, reliable partner who can actually help your business grow. It’s about more than just a quick Google search; you need to dig in and make sure their quality, capabilities, and even their company culture are a perfect match for yours.

Think of it like hiring a key member of your team. You wouldn't hire someone just from their resume, right? You’d interview them, check their references, and see if they fit. Vetting a supplier is no different. You have to look past the price sheet.

Where to Start Your Search

Finding top-notch domestic suppliers means knowing where to look. While a general search engine can get you started, you'll get much better results by using more targeted resources.

- Industry-Specific Directories: Platforms like Thomasnet or Maker's Row are fantastic places to start. They offer detailed profiles of manufacturers and suppliers across tons of different industries.

- Trade Shows and Conferences: There's no substitute for meeting people face-to-face. Industry events let you see their products up close, ask questions, and get a real feel for who you might be working with.

- Local Business Associations: Don't forget to check in your own backyard. Your local Chamber of Commerce or manufacturing groups can be a great source for recommendations on reputable suppliers right in your region.

Your Vetting Checklist

Once you have a shortlist of potential partners, it's time to do your homework. A methodical approach here will save you a world of headaches later. This checklist is the framework I've used time and again to make the right choice.

-

Request and Evaluate Samples: This is an absolute must. You have to get your hands on their work to judge the quality for yourself. For anyone in the apparel game, that means feeling the materials, checking the print quality, and looking at the fine details. If you're new to this, get a feel for what to look for by reading our guide on DTF vs. DTG printing.

-

Verify Certifications and Capabilities: Don't be shy about asking the tough questions. What's their production capacity? What kind of equipment are they running? Do they hold any quality certifications, like ISO 9001? A great supplier will be transparent and proud to show off their credentials. This tells you if they can handle your orders now and scale with you down the road.

-

Assess Communication and Responsiveness: Pay close attention to how they interact with you from the very first email. Are they quick to respond? Are their answers clear and professional? If communication is a struggle from the get-go, it’s a massive red flag for how they'll handle any issues that pop up later.

A supplier isn't just a vendor; they are an extension of your own team. Their reliability directly impacts your brand's reputation. Choose a partner whose commitment to quality and communication mirrors your own.

By following these steps, you can confidently choose a US-based supplier who doesn’t just meet your production needs but becomes a genuine asset to your business.

Navigating the Challenges of Domestic Sourcing

While the upside is huge, choosing made in usa suppliers isn’t always a walk in the park. It comes with its own set of hurdles, and being realistic about them from the start is the best way to turn potential problems into smart business advantages. Making the switch isn't always simple, but a well-thought-out plan can pay off big time.

Let's be honest, the first thing everyone talks about is cost. It’s no secret that higher labor wages and stricter regulations in the U.S. often mean a higher price tag per item compared to what you'd find overseas. For businesses fighting for every penny in a competitive market, that initial sticker shock can be a real roadblock.

On top of that, the pool of domestic suppliers can sometimes feel smaller, especially if you're looking for niche parts or highly specialized materials. Years of manufacturing moving overseas meant certain industries became concentrated elsewhere. This means you might have to dig a bit deeper to find the right partner or even work with them to create a custom solution. Knowing the ins and outs of materials, like the difference between cotton vs. polyester, becomes critical, as local availability can be a major factor.

Overcoming Hurdles with Innovation

But here's the thing: American manufacturers aren't just sitting back. They're aggressively closing the cost and capability gap through smart innovation and a laser focus on total efficiency—not just the price of a single unit.

This push for progress is a direct answer to the chaos of the last few years. With supply chain nightmares hitting a staggering 77% of manufacturers, companies are scrambling for smarter ways to manage logistics and production. It’s not just talk; recent data shows a 40% jump in the adoption of automation and AI in just one year. This isn't just a trend; it's a fundamental shift toward making domestic operations stronger and more efficient.

All this new tech helps offset higher labor costs by cranking up productivity and slashing waste.

The modern American factory floor looks a lot different these days. It’s becoming a hub for advanced robotics and data-driven systems. This isn’t about replacing people—it’s about giving them the tools to make better products more efficiently than ever before.

Building Proactive Partnerships

To really win at domestic sourcing, you need to do more than just find a supplier. You need to build a genuine partnership, and that starts with open, honest communication.

Here are a few strategies to help you get ahead of any potential challenges:

- Plan for the Long Haul: Don't just place one-off orders. Work with your supplier on forecasting your demand. When they have a clear idea of what you'll need down the road, they can manage their own inventory and production schedules better. This often translates to better pricing and VIP service for you.

- Solve Problems Together: Stop thinking of your supplier as just a vendor. Treat them like an extension of your own team. When a problem pops up—and it will—tackle it together. Maybe that means tweaking a design to make it easier to manufacture or exploring a different material that's more readily available.

Building a Strong Partnership with Your Supplier

Sourcing from made in USA suppliers is more than just a transaction; it's about building a relationship that can become one of your most powerful business assets. The smartest companies I've seen don't treat their suppliers like just another line item on a spreadsheet. They build real, strategic partnerships based on trust, open communication, and shared goals.

Think of it like this: a transactional relationship is like hiring a plumber to fix a single leak. A partnership is like having a master builder on your team, someone who understands the entire blueprint and is as invested in the success of the project as you are. This simple mental shift—from vendor to partner—is the key to getting the most out of sourcing domestically.

From Vendor to Valued Partner

So, how do you make that happen? It all starts with clear, honest communication. Don't just fire off purchase orders into the void. Share your vision. When your supplier understands what you're trying to achieve with your brand, they can bring ideas to the table you might never have thought of. That collaborative spark is where the real value gets created.

A strong supplier partnership acts as a force multiplier for your business. It turns your supply chain from a potential weakness into a source of competitive advantage, innovation, and resilience.

A huge piece of this is sharing transparent demand forecasts. When your supplier has a decent idea of what you'll need over the next few months, they can manage their own production schedules and material orders far more effectively. Just sharing that information can lead to better pricing for you, priority treatment, and a supplier who's willing to hustle for you when you're in a pinch.

Laying the Groundwork for Mutual Growth

A real partnership is a two-way street; it has to work for both of you. When you invest in a long-term connection, you’re not just getting a reliable source for your products—you’re building a stronger, more flexible business from the ground up.

Here’s how you can actively nurture that kind of growth:

- Collaborate on Innovation: Bring your supplier into the loop early on new product ideas. Their hands-on manufacturing knowledge can help you tweak designs for better quality and cost-effectiveness before you're too far down the road.

- Establish Shared Goals: Work together on goals, whether it’s hitting a new quality benchmark, finding ways to trim costs, or shortening lead times. This gets everyone pulling in the same direction.

- Provide Constructive Feedback: Set up a regular, open channel for feedback. Talk about what's working well and what could be better. This constant back-and-forth builds trust and keeps everyone improving.

When you take this approach, your supplier stops being just a name on an invoice. They become a critical part of your success story.

Frequently Asked Questions About US Suppliers

When you start digging into the world of made in USA suppliers, a few key questions always seem to pop up. It's only natural to wonder about cost, legitimacy, and where American manufacturing really shines.

Let's clear the air and tackle some of the most common questions head-on. Getting these answers straight is the first step toward making a sourcing decision you can feel good about.

Is Sourcing from US Suppliers Always More Expensive?

Not when you look at the whole picture. It's easy to get sticker shock from a higher per-unit price, but that number rarely tells the full story. The real metric to watch is the total cost of ownership.

Think about it: with a US supplier, you're looking at much lower shipping fees, no surprise import tariffs, and drastically shorter lead times. That last part is huge—it means your cash isn't tied up for weeks in inventory that's stuck on a boat. When you add it all up, sourcing domestically often comes out ahead.

A slightly higher per-unit cost can be a fantastic investment. Fewer defects and faster turnarounds mean less wasted product and quicker sales, which is what really impacts your bottom line.

How Can I Verify a Supplier's "Made in USA" Claim?

This is a great question, and luckily, there are rules for this. A legitimate "Made in USA" claim is regulated by the Federal Trade Commission (FTC). Their standard is tough: "all or virtually all" of the product has to be made right here in the States.

So, how do you check?

- Ask for documentation. A transparent supplier won't hesitate to show you where their materials come from.

- Request a factory tour. There's no better proof than seeing the production line with your own eyes.

- Look for third-party certifications. These official seals of approval can validate a supplier's claims.

A supplier who is genuinely proud of their American roots will be more than happy to prove it.

What Industries Have the Strongest US Supplier Base?

The U.S. has always been a manufacturing powerhouse in certain sectors, known for pushing the envelope on quality and innovation.

You'll find incredibly robust supplier networks in industries like aerospace, automotive, complex industrial machinery, and medical devices. And closer to home for us, specialized textiles—the kind needed for top-tier DTF printing—have a competitive and thriving domestic market.

Ready to see what a true "Made in USA" supplier can do for your DTF printing business? At Cobra DTF, we provide premium, American-made transfers that deliver incredible color and durability. You get fast turnarounds and straightforward pricing, with no hidden fees.

Discover the difference that speed and quality make. Explore our products at https://cobradtf.com today.