Dye Sublimation vs Heat Transfer for Custom Products

Share

At its core, the difference between dye sublimation and heat transfer is pretty straightforward. Dye sublimation turns ink into a gas that actually becomes part of the material, while heat transfer lays a separate layer on top of it. The right choice really comes down to what you value more: a permanent, zero-feel finish (sublimation) or the flexibility to print on almost any fabric or color (heat transfer).

Choosing the Right Customization Method

Picking between dye sublimation and heat transfer is one of the first major decisions you'll make when starting a custom apparel or product business. They are both incredibly popular, but the science behind them couldn't be more different. Those differences have a massive impact on the final product's look, feel, durability, and what you can even print on. Getting this right from the start is key to aligning your equipment with your business goals, your budget, and the quality your customers expect.

Once you've landed on a printing method, you'll want to think about how it fits into your broader sales plan, which should include a solid e-commerce content strategy. It's worth noting that the demand for dye sublimation is exploding. The global market is expected to hit USD 7.4 billion by 2030, a testament to its growing grip on the textile industry.

A Quick Comparison

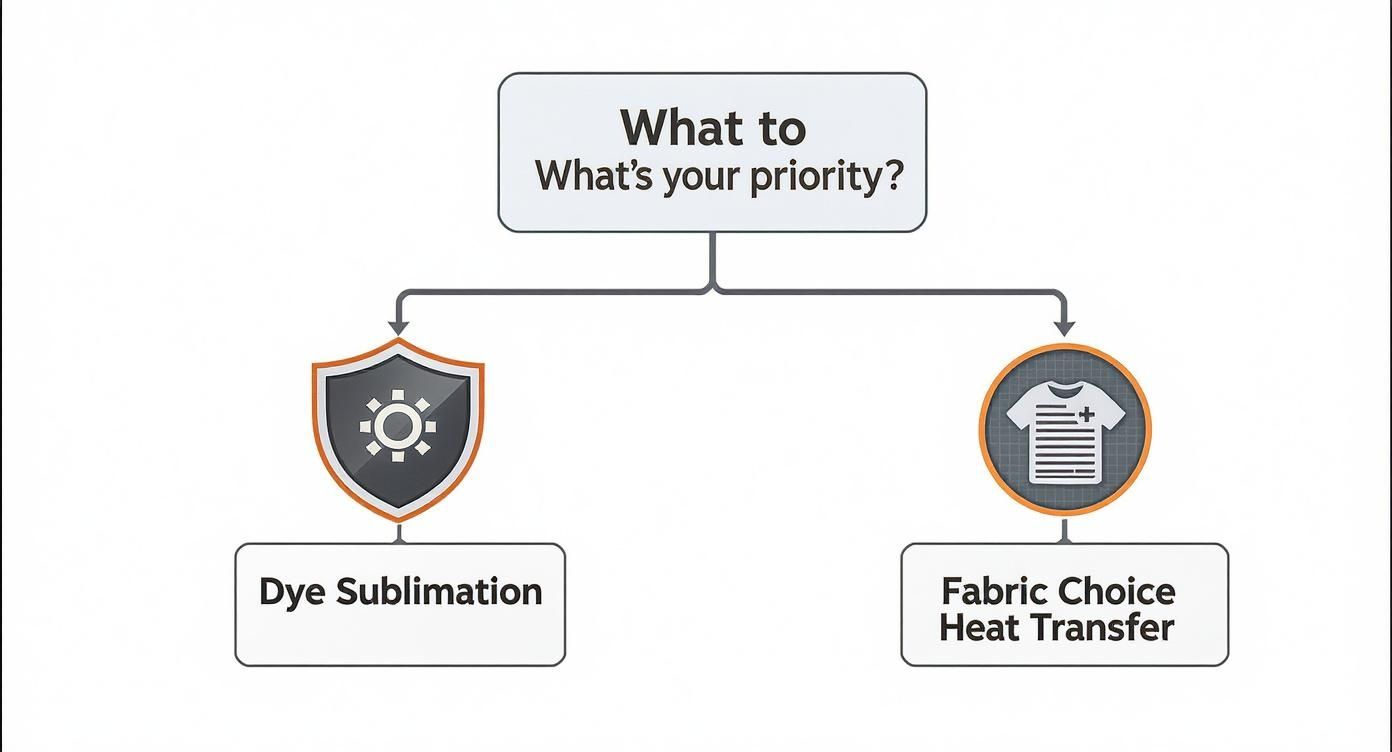

To get a feel for which path is right for you, this decision tree lays out the primary choice you'll face: ultimate durability vs. broad fabric compatibility.

As you can see, if you need a design that will never fade, crack, or peel, dye sublimation is your answer. But if you need to print on a wide range of materials, heat transfer is the way to go.

To really get into the weeds, I've put together a table that breaks down the most important distinctions. It’s a great starting point for seeing how these two methods stack up before we dive deeper into each one.

Quick Comparison of Printing Methods

This table offers a side-by-side summary to help you quickly weigh the key factors.

| Attribute | Dye Sublimation | Heat Transfer |

|---|---|---|

| Feel of Print | No texture; the ink is part of the fabric. | A distinct layer sits on top of the fabric. |

| Durability | Permanent; will not crack, peel, or fade. | Limited lifespan; can crack or peel over time. |

| Material | Polyester or polymer-coated items only. | Works on cotton, polyester, blends, and more. |

| Fabric Color | Best on white or light-colored fabrics. | Works on fabrics of any color, including black. |

| Ideal For | Full-color photos, athletic wear, mugs. | Bold logos, text, simple graphics on cotton. |

Think of this as your cheat sheet. Each method has its place, but they solve very different problems. Now, let’s get into the specifics of how each one works.

How Each Printing Process Actually Works

To really get to the bottom of the dye sublimation vs. heat transfer debate, you have to understand what’s happening at a chemical and physical level. Both methods use a heat press, sure, but how they get a design onto a product couldn't be more different. One process literally becomes part of the material, while the other sits right on top.

Knowing the nuts and bolts of each is the first real step in picking the right tech for your shop, whether you're decking out a sports team in performance gear or printing a batch of cotton promo tees.

The Science of Dye Sublimation

Dye sublimation is pure chemistry in action. It all starts with printing your design onto special transfer paper using sublimation inks. You then place this paper onto a polyester or polymer-coated substrate and introduce it to a heat press cranked up to around 400°F (200°C).

This is where the magic happens. The intense heat causes the solid ink on the paper to bypass the liquid state and turn directly into a gas—a process called sublimation. This gas then seeps into the now-open pores of the polyester. As it cools, the pores close up, permanently trapping the ink within the very fibers of the material.

The result is a print that’s not just on the fabric, but in it. There's no texture or "hand," meaning you can't feel the design at all. It’s as smooth and breathable as the original garment.

This complete fusion of ink and fiber is exactly why sublimation reigns supreme in certain niches. In fact, apparel makes up 62.78% of the dye sublimation market, primarily because it's perfect for the seamless, all-over prints you see on activewear and high-fashion pieces. You can read more about this trend in the dye sublimation printing market report.

Want to go even deeper? Check out our detailed guide on what is sublimation printing and how it works.

The Application of Heat Transfer

Heat transfer, which you’ll often hear called heat transfer vinyl or HTV, works on a much simpler principle: adhesion. Instead of becoming one with the fabric, the design is essentially glued to the surface.

Here's how it breaks down:

- Design Cutting: Your design is first cut out from a sheet of heat transfer material, like vinyl, using a vinyl cutter or plotter.

- Weeding: You then have to manually remove all the excess vinyl from around your design. This process is called "weeding," and it leaves just your graphic on its clear plastic carrier sheet.

- Application: Finally, you position the weeded design on the garment and press it with a heat press.

The combination of heat and pressure activates the adhesive on the back of the vinyl, fusing it to the surface of the fabric. You can think of it as a super durable, professionally applied sticker. This creates a distinct layer you can feel, but its biggest strength is its incredible versatility. It sticks to almost anything—cotton, polyester blends, and even dark-colored fabrics where sublimation just won't work.

Comparing Print Quality and Long-Term Durability

When you get right down to it, the look, feel, and lifespan of a product are where the real differences between dye sublimation and heat transfer pop. One method gives you a permanent, photo-quality image you can't even feel, while the other creates a bold, tactile graphic that sits right on top of the material. Getting this choice right is all about matching the final product to what your customer expects and how they'll actually use it.

Pick wrong, and you might end up with a super durable print that looks washed out on a dark shirt, or a gorgeous design that starts peeling after just a few washes. Let's break down how each method really performs when it comes to visual quality and holding up over time.

Visual Quality and Color Vibrancy

The final look you get from these two methods couldn't be more different. Dye sublimation is the undisputed champion for photorealistic images, capable of producing millions of colors and buttery-smooth gradients. Because the ink turns into a gas and bonds inside the polyester fibers, you get a continuous tone with no dots or pixelation. This makes it the only real choice for complex, full-color photos or intricate all-over patterns.

Heat transfer vinyl (HTV), on the other hand, is all about big, bold, opaque graphics. It’s a solid layer of material applied to the fabric’s surface, so its colors are incredibly punchy and crisp. This is especially true on dark-colored garments where sublimation simply won't work. It’s absolutely perfect for vector graphics like logos, text, and team numbers that need to pop with clean, sharp edges.

Key Takeaway: If your design is a detailed, multi-color photograph going on a light-colored polyester shirt, sublimation is your winner, no question. But if you need a solid, bright white logo on a black cotton hoodie, heat transfer delivers the opacity and impact you need.

The Critical Role of Durability and Longevity

Durability is probably the single biggest separator in the dye sublimation vs. heat transfer debate. A sublimated print is, for all intents and purposes, permanent. Since the ink becomes part of the material itself, the design will last as long as the garment does. It’s completely immune to the common problems that plague other print methods.

A sublimated graphic will never:

- Crack or Peel: There’s no layer on the surface to break down or lift off.

- Fade in the Wash: The ink is locked deep inside the polyester fibers, making it incredibly resistant to fading from laundering.

- Block Fabric Breathability: The process doesn't clog the fabric's weave, which is why it's ideal for performance and athletic apparel.

Heat transfer prints have a much more limited lifespan. The vinyl is essentially glued to the top of the fabric, making it vulnerable to the stress of wearing, washing, and stretching. Over time, HTV designs can start to crack, peel up at the edges, or fade with repeated runs through a hot dryer. While a high-quality vinyl can easily last for 50+ washes with proper care, it will eventually show its age.

Real-World Scenarios and Recommendations

To make this crystal clear, let's walk through two common scenarios you might face in your business.

Scenario 1: Custom Athletic Jerseys

A local soccer team needs new jerseys. These things are going to be stretched, drenched in sweat, and thrown in the wash after every single game.

- Recommendation: Dye Sublimation. The permanent, breathable, and uncrackable nature of a sublimated print is essential for athletic wear. The design will easily outlast the season without fading or peeling, keeping the team looking sharp.

Scenario 2: Promotional T-Shirts for an Event

A company wants 100 cotton t-shirts printed with their bold, single-color logo for a one-day trade show.

- Recommendation: Heat Transfer. HTV is the perfect tool for this job. It’s cost-effective for smaller batches, works great on cotton, and will produce a vibrant, opaque logo that stands out. Long-term durability isn’t the main concern for a promotional item with a short-term purpose.

Ultimately, your choice has to be guided by the product’s end-use. For premium, long-lasting retail goods or high-performance gear, sublimation offers durability that can’t be beaten. For promo items, fashion pieces with bold graphics, or printing on cotton and other natural fibers, heat transfer provides the versatility and visual punch to get the job done right.

Understanding Material and Substrate Compatibility

When you're deciding between dye sublimation and heat transfer, the first question I always ask is: "What are you printing on?" Your answer will pretty much make the decision for you. These two methods have very different, and very strict, rules about the materials they play nice with. Get it wrong, and you're not just looking at a bad print—you're looking at a complete failure that wastes your time, money, and blank products.

Let's break down which process is the right tool for the job, whether you're decorating cotton hoodies, performance jerseys, or ceramic mugs.

Dye Sublimation: The Polyester Specialist

Dye sublimation is an amazing process, but it's incredibly picky. It’s all about a chemical reaction where solid ink turns into a gas and literally becomes one with polymer fibers. This scientific magic means it only works on very specific materials.

The non-negotiable rule for sublimation is that your item must be made of polyester or have a special polymer coating. The process flat-out fails on natural fibers like cotton or on any hard surface that hasn't been pre-treated for sublimation.

Materials That Work with Sublimation:

- 100% Polyester Apparel: Think performance wear, athletic jerseys, and a lot of modern activewear.

- High-Polyester Blends: You can get away with fabrics that have at least 50-60% polyester, but be warned—the colors will look faded or "vintage" because the ink only bonds to the polyester threads, not the cotton.

- Polymer-Coated Hard Goods: This is where things get fun. Sublimation is fantastic for specially prepared mugs, phone cases, keychains, and metal plates.

Another crucial point: sublimation ink is translucent. It dyes the fibers, it doesn't cover them. This means you need a white or very light-colored background for your design to show up properly. Trying to sublimate on a black polyester shirt will give you... well, a black polyester shirt. Nothing will be visible. For more on how these fabrics behave, check out our deep dive into cotton vs polyester.

Heat Transfer: The Do-Anything All-Rounder

If sublimation is the specialist, heat transfer is the jack-of-all-trades. Instead of dyeing the fabric, it applies a layer of material on top of it. This simple difference makes it compatible with a massive range of materials and colors.

Whether you're using heat transfer vinyl (HTV) or printed transfers, you can apply them to just about any fabric that won’t melt under the heat press.

Materials That Work with Heat Transfer:

- Cotton and Cotton Blends: This is its bread and butter. Perfect for the classic t-shirts, hoodies, and tote bags everyone loves.

- Polyester and Blends: Works just as well on polyester as it does on cotton, no problem.

- Specialty Fabrics: With the right kind of transfer material, you can decorate trickier items like nylon, leather, and even spandex.

The biggest win for heat transfer? It works on any color, including black. The opaque transfer material sits on top of the fabric, so the garment’s color can’t bleed through. Your design stays bright and true, no matter the background.

To give you a clearer picture, I've put together a quick-reference matrix. This should help you see at a glance which method fits the products you want to create.

Material and Substrate Compatibility Matrix

| Material Type | Dye Sublimation Suitability | Heat Transfer Suitability | Best Use Case |

|---|---|---|---|

| 100% Polyester | Excellent | Excellent | Sublimation for full-color, no-feel prints on light garments; Heat Transfer for dark garments or specialty finishes. |

| Polyester Blends | Fair to Good (Faded look on blends < 60% poly) | Excellent | Heat Transfer for vibrant, consistent colors on any blend. |

| 100% Cotton | Not Compatible | Excellent | The go-to for Heat Transfer, especially for classic t-shirts and hoodies. |

| Nylon/Leather/Spandex | Not Compatible | Good (Requires specific vinyl/transfer type) | Heat Transfer using materials designed for these specialty fabrics. |

| Coated Hard Goods | Excellent (Must be "sublimation-ready") | Limited (Some specialized vinyls exist) | Sublimation is the clear winner for mugs, tiles, and metal. |

As you can see, your product choice dictates your printing method. While the market for dye sublimation is substantial—it holds about 47.6% of the global heat transfer paper market—the sheer versatility of traditional heat transfer makes it an essential tool for any shop that wants to offer a wide variety of products to a diverse customer base.

Breaking Down the Costs and Production Speed

When you're deciding between dye sublimation and heat transfer, you're not just picking a printing method—you're making a core business decision. The money you'll spend upfront, the cost of your supplies, and how fast you can actually get orders out the door are all on the line. These factors will shape what kind of business you can build.

Lots of people think the initial investment is similar because, hey, you need a heat press for both, right? But that's where the similarities end. The real story is in the specialized gear and consumables that each process demands. Let's dig into what it really costs to get started.

The Upfront Investment: What You'll Spend to Get Started

Heat transfer is undeniably the more budget-friendly way to get into the game. It’s got a lower barrier to entry, which is a huge plus for new businesses testing the waters. The equipment list is pretty simple.

Heat Transfer Starter Setup:

- Vinyl Cutter: This is your main tool. You can grab a hobbyist model for around $300, but a professional-grade machine will run you closer to $2,000.

- Heat Press: Don't skimp here. A solid 15x15-inch clamshell press is a workhorse, and a reliable one will cost between $300 and $700.

- Weeding Tools & Software: These are small but essential costs, usually adding up to less than $100.

Dye sublimation, on the other hand, asks for a bigger commitment from your wallet right away. You don't need a cutter, but the printer and ink system are specialized and come with a higher price tag.

Dye Sublimation Starter Setup:

- Sublimation Printer: You can't just use any old inkjet. A dedicated sublimation printer, like an entry-level Sawgrass, starts at about $600 and can easily jump past $2,500 for larger formats.

- Sublimation Inks & Paper: These aren't your standard office supplies. A starter pack of the special inks and paper will typically run between $100 and $300.

- Heat Press: Good news here—the same press works for both. This cost is a wash if you plan to offer both services down the line.

The bottom line? You can cobble together a decent heat transfer setup for under $800. For a comparable entry-level sublimation kit, you're looking at a starting point of around $1,200, if not more.

Production Speed and Scaling Up

Okay, you've bought the gear. Now, how quickly can you make things? This is where the two methods really diverge, and where your business goals become critical.

Heat transfer is king for one-off custom jobs. Got an order for a single t-shirt with a name on the back? Perfect. Cutting, weeding, and pressing one design is fast and straightforward. It’s built for on-demand work.

But what happens when an order for 50 shirts with a complex logo comes in? That’s when the manual labor of weeding vinyl becomes a serious bottleneck. Meticulously picking out tiny pieces of vinyl from 50 different transfers is incredibly time-consuming and just doesn't scale efficiently.

This is exactly where dye sublimation pulls ahead.

For larger batches, sublimation is a game-changer. Once you have your design printed on the transfer sheets, you can press one after another with incredible consistency. There's zero weeding involved, which slashes your per-item labor time. If you’re printing for a local sports team, a corporate event, or a school fundraiser, sublimation is your friend. You could easily print 100 sublimation transfers in the time it takes to weed just a handful of intricate vinyl designs, completely streamlining your workflow for bulk orders.

When to Choose Direct-to-Film (DTF) Transfers Instead

So far, the choice seems to be between the incredible permanence of dye sublimation and the material flexibility of heat transfer. But what if you didn't have to choose? What if there was a third way that gave you the best of both? That’s exactly where Direct-to-Film (DTF) printing comes in, and it's a real problem-solver.

DTF essentially bridges the gap. It delivers the stunning, full-color, detailed prints we love about sublimation, but with the freedom to print on almost anything, just like heat transfer. The final prints are vibrant, super soft to the touch, and have fantastic stretch and durability. For any shop that wants to deliver top-tier quality without being limited by materials, DTF is a powerful tool to have.

Solving the Fabric Dilemma

Let's be honest, the biggest hurdle with dye sublimation is its strict polyester-only diet. And while heat transfer vinyl (HTV) can handle cotton, it often leaves a thick, plastic-like feel that can crack over time. DTF completely sidesteps these issues, working beautifully on a massive range of fabrics.

DTF is the go-to when other methods just can't get the job done:

- 100% Cotton and Blends: Finally, you can get bright, photorealistic designs on the world's most popular t-shirt material.

- Dark-Colored Garments: This is a huge one. Unlike sublimation, DTF prints are completely opaque. This means brilliant whites and vivid colors look incredible on black, navy, or any dark-colored shirt.

- Polyester and Nylon: On synthetics, it offers a much softer and more flexible feel than you'd typically get from traditional heat transfer methods.

For businesses that want to say "yes" to more customers, DTF is a game-changer. You no longer have to turn away a client who wants their detailed, full-color logo printed on a black cotton hoodie—a job that's impossible for sublimation and a nightmare for HTV.

When DTF is the Clear Winner

The goal isn't to replace sublimation or HTV entirely. It’s about having the right tool for the right job. You'll want to reach for DTF when a project's needs are a mix of features that neither of the other two methods can handle on their own.

Imagine this scenario: a client needs their intricate, multi-color company logo printed on a batch of premium black cotton polo shirts. Sublimation is immediately out because of the fabric type and color. Trying to layer multiple colors of HTV would be a huge headache, take forever, and result in a thick, stiff design. This is exactly where DTF shines. It delivers a clean, lightweight, and durable print without the hassle.

This method truly combines the vibrant, detailed results of sublimation with the print-on-anything capability of heat transfer. To see how it can open up your product lineup, you can learn more about what is Direct-to-Film printing and see the process for yourself. At the end of the day, DTF is the modern answer for creators who demand premium results on pretty much any garment they can think of.

Common Questions We Hear All the Time

Even after you've weighed all the technical details, materials, and costs, a few practical questions always seem to pop up. These are the things people ask right before they pull the trigger on a big purchase, and getting them sorted out is key to avoiding costly mistakes. Let's dive into the most common questions we get from folks trying to decide between dye sublimation and heat transfer.

These are the nitty-gritty, day-to-day concerns that move you from theory to the reality of running a print shop.

Can I Just Use My Regular Office Printer for Sublimation?

I wish I could say yes, but this is one of the most frequent misconceptions, and the answer is a hard no. Your standard inkjet printer is loaded with regular ink meant for paper. It simply doesn't have the chemical properties needed for sublimation—that magical process where a solid ink turns into a gas.

To get started with sublimation, you absolutely need two things:

- Sublimation Ink: This is a special formula designed to vaporize under heat.

- Sublimation Paper: This isn't just any paper; it's coated to hold the ink perfectly and then release it as a gas when you press it.

You either need a printer built specifically for sublimation (like those from Sawgrass) or an inkjet printer that's been officially converted for it. Certain Epson models are popular for this kind of conversion. If you try to use regular ink, you'll just end up with a soggy, inky mess on your transfer paper and a ruined product.

Which Method Is Better if I’m Starting a Small Business From Home?

For most people just starting out, heat transfer vinyl (HTV) is hands-down the easier and cheaper way to get in the game. The initial cost for a good vinyl cutter and a heat press is just much lower than a full sublimation setup, which makes it a far less risky investment when you're testing the waters.

The real win for a home-based business is the flexibility. With heat transfer, you can grab a pack of affordable cotton t-shirts in any color and start printing immediately. Those are the kinds of products that are easiest to sell when you're building your first customer base.

Dye sublimation creates an incredible, permanent print, but its biggest hurdle is the material limitation. It only works on polyester or specially polymer-coated items. Finding those specific blanks can be a challenge at first, and you'll spend a lot of time explaining to customers why their design can't go on a classic cotton tee.

How Do I Stop My Sublimation Prints From Looking Blurry or Ghosted?

Ah, the dreaded ghosting. Seeing a blurry image or a faint, shadowy double of your design is a classic sublimation headache, but it’s almost always fixable. This happens when the transfer paper moves—even a tiny bit—while the ink is in its gaseous state during or right after pressing.

To get a razor-sharp transfer every single time, just lock down your process:

- Tape It Down: Always, always use high-temperature resistant tape to stick the sublimation paper securely to your product. Don't be stingy with it; a piece on each corner is a good start.

- Get the Pressure Right: Make sure your heat press is applying firm and perfectly even pressure across the entire item. Uneven pressure is a recipe for a blurry spot.

- Lift, Don't Slide: When the timer goes off, open the press and lift the top platen straight up. Any sideways dragging motion can smear the still-hot design.

- Let It Cool: On many items, just waiting a few seconds for it to cool down before peeling the paper helps the ink set and prevents smudging.

Ready to unlock vibrant, full-color designs on any fabric without compromise? Cobra DTF offers premium, USA-made Direct-to-Film transfers that provide the soft feel and durability you need to elevate your products. Explore our high-quality DTF transfers and see the difference at https://cobradtf.com.