A Guide to DTF Transfer Sheets Ready to Press

Share

Imagine having a professional-quality, full-color design that's ready to go, waiting to be pressed onto almost any fabric. That's exactly what a ready to press DTF transfer sheet is. These are pre-made designs printed on a special film that you apply with a simple heat press.

They arrive at your door completely finished, letting you create stunning custom apparel and accessories without needing your own expensive DTF printer. This makes them a fantastic choice for everyone from at-home crafters to established businesses looking to expand their offerings.

What Are Ready to Press DTF Transfers

It helps to think of a DTF transfer sheet ready to press as a high-end, super-durable decal made specifically for fabric. If you've ever used a classic iron-on, you know they can sometimes feel thick and sit like a sticker on top of the shirt. DTF is a whole different ballgame.

DTF transfers bond directly into the fabric fibers. This creates a finish that’s not just soft and flexible but also incredibly resilient, standing up to wash after wash.

The secret lies in the "DTF" (Direct to Film) process. A design is printed with vibrant, specialized inks onto a clear film. A fine adhesive powder is then applied to the back of the ink and melted, creating a perfect, prepped design that's just waiting for a heat press.

The "Ready to Press" Advantage

That little phrase—"ready to press"—is what makes all the difference. It means the complicated, technical part of the printing process is already handled for you by experts with professional equipment.

You don't have to worry about buying or maintaining a six-figure printer, messing with inks, or figuring out the curing process. You just pick your designs, place an order, and they show up ready for you to press onto your garments. This convenience is what makes dtf transfer sheets ready to press so powerful.

To get a full picture of the technology, our complete guide on what DTF transfers are breaks down the entire process from start to finish.

This streamlined approach gives creators a massive leg up:

- No High Barrier to Entry: You can start producing professional-level custom products without a huge upfront investment in equipment.

- Guaranteed Quality: Since every transfer is printed on commercial-grade machinery, you get consistent, vibrant, and reliable results every single time.

- Incredible Speed: Forget lengthy setup times. You can press a finished garment in a matter of minutes, making it easy to handle both one-off custom jobs and large bulk orders.

Essentially, you get to tap into all the perks of top-tier printing technology—eye-popping colors, amazing durability, and a soft-to-the-touch feel—without any of the headaches or costs. It’s the perfect bridge between DIY projects and full-scale commercial production.

To quickly sum it up, here's a look at the key features that make these transfers so effective.

Key Features of Ready to Press DTF Transfers

This table provides a quick overview of the essential characteristics that make pre-made DTF transfers a powerful choice for custom printing.

| Feature | What It Means for You | Practical Benefit |

|---|---|---|

| No Printing Required | The designs arrive pre-printed, cured, and ready for application. | You can start a custom apparel business with just a heat press and your ideas. |

| Full-Color & Gradients | Capable of reproducing millions of colors, fine details, and smooth gradients. | Perfect for photorealistic images, complex logos, and artistic designs. |

| Fabric Versatility | Adheres to cotton, polyester, blends, canvas, denim, and even leather. | You're not limited to one type of garment; you can decorate almost anything. |

| Superior Durability | Transfers stretch with the fabric and are rated for 50+ washes. | Your products will look great for a long time, leading to happy customers. |

| Soft-Hand Feel | The ink bonds with the fabric, resulting in a thin, flexible feel. | Creates a premium, retail-quality product that people love to wear. |

Ultimately, ready to press transfers put the power of a commercial print shop right at your fingertips, accessible with nothing more than a heat press.

The Big Wins: Why DTF Transfers Are a Game Changer

So, what’s all the hype about? When you start digging into DTF transfers, you quickly see why so many creators and businesses are hooked. The benefits aren't just about printing a cool design; they change the entire game for custom apparel and product making, especially if you don't have a giant warehouse full of equipment.

The biggest advantage, by far, is their incredible versatility. Forget printing methods that are fussy about fabrics. DTF transfers are like the universal remote for your creative ideas—they just work, on almost anything.

Go Way Beyond T-Shirts

Sure, they’re fantastic on your standard cotton, polyester, and poly-blend shirts. But that’s just the beginning. This technology lets you press full-color, eye-popping designs onto all sorts of surfaces, unlocking totally new product lines you might not have considered before.

Just think about what you could create:

- Tough Stuff: Put detailed logos on rugged materials like denim jackets or heavy-duty canvas tote bags.

- Hard Goods: Decorate things like treated wood signs or even create custom-branded leather patches.

- Performance Gear: Get crisp, lasting designs on slippery athletic jerseys that need to stretch and move.

This freedom means you’re no longer boxed in by your equipment. If you can safely get it under a heat press, chances are you can put a DTF transfer on it. Imagine being an Etsy seller and offering the same beautiful design on a t-shirt, a canvas backpack, and a wooden memory box, all without breaking a sweat.

Built to Last, Wash After Wash

Another huge plus is their durability. We’ve all seen custom shirts where the design cracks, peels, or fades after just a few trips through the laundry. High-quality dtf transfer sheets ready to press are designed to fuse right into the fabric, creating a bond that holds on for dear life.

This isn't just a small improvement; it's a massive leap forward. These transfers are often rated for 50+ washes without losing their color or peeling away. The print stretches right along with the fabric, so you don't get that stiff, cracked look that plagues older methods. Your products won’t just look great on day one—they’ll stay looking great for a long, long time.

For a small business, that kind of durability is pure gold. It builds trust. When a local soccer team’s jerseys still look sharp at the end of the season, or a family's reunion shirts last for years, that’s your brand’s reputation for quality getting stronger with every wash.

At the end of the day, DTF transfers are about making professional quality accessible. They cut out the steep costs, messy inks, and constant maintenance of other printing methods. This puts small businesses and solo creators on a level playing field, letting them produce top-tier products quickly and on-demand without needing a fortune in equipment.

A Look Under the Hood: DTF Printing Technology and Films

To really get the most out of your dtf transfer sheets ready to press, it helps to understand a bit about the technology behind them. The real magic is in the transfer film, and you'll typically run into two main types: cold peel and hot peel. Each has its own job, and picking the right one can make your production life a lot easier and your final products look that much better.

Think of it like choosing the right kind of glue. A cold peel film is your slow-curing, super-strong epoxy. After you press the design, you have to let it cool down completely before you can peel the film away. This waiting game allows the adhesive to set up a rock-solid bond, making it the go-to choice for designs with tiny text or really intricate, delicate details that need to stick around.

A hot peel film, on the other hand, is like a quick-set craft glue. You can yank that film right off the garment almost as soon as the heat press opens. This is all about speed and efficiency. It’s perfect for high-volume jobs with simpler, bolder graphics where you're trying to crank through a stack of shirts.

Hot Peel vs. Cold Peel: The Main Differences

Choosing between hot and cold peel film isn't just about what you feel like using that day; it actually changes your workflow and the final look of the print. A cold peel transfer tends to leave a slightly glossier, smoother finish because the adhesive has more time to settle and bond. In contrast, hot peel transfers usually have a more matte appearance, which a lot of people love for that modern, retail-ready vibe.

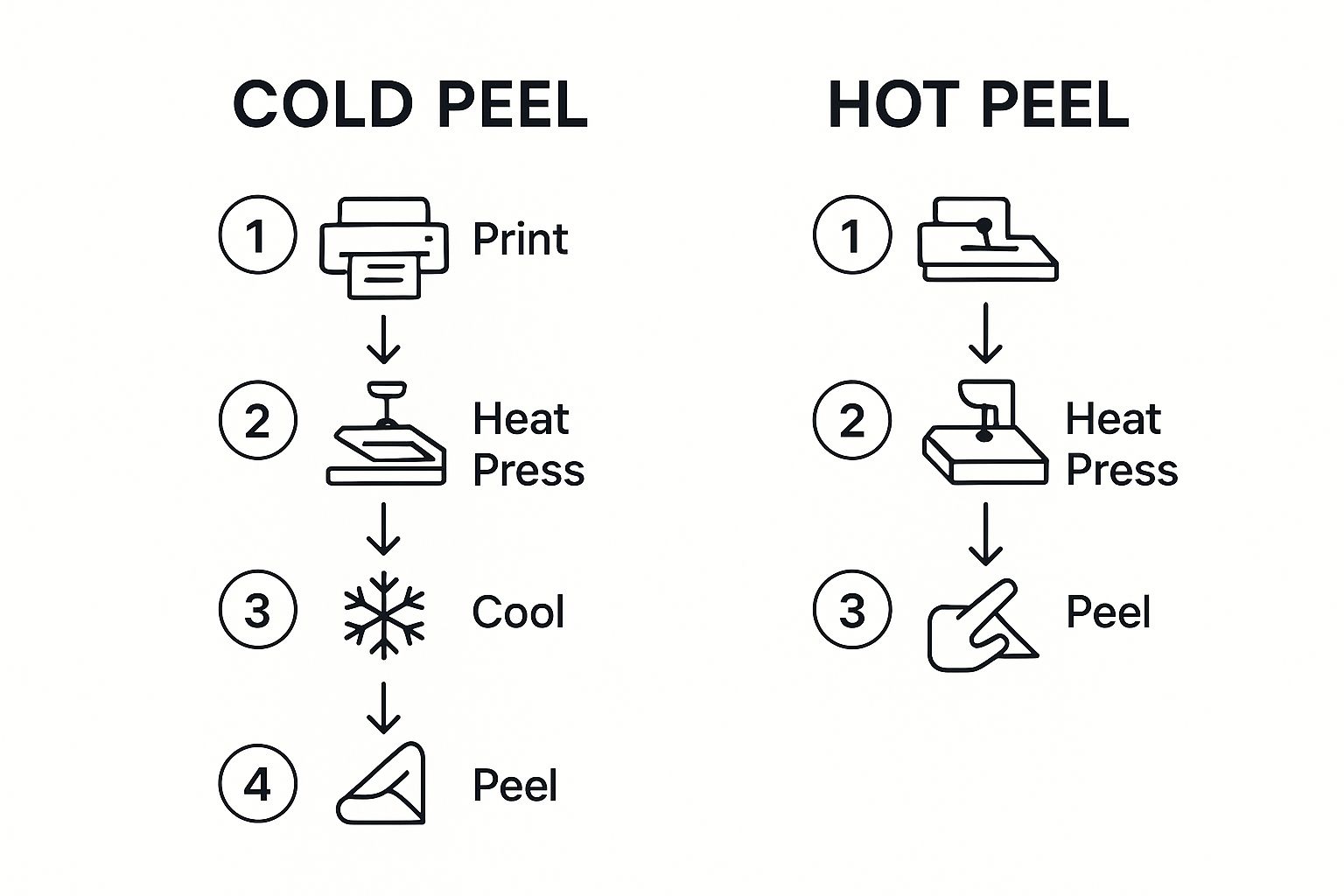

This infographic really nails the core difference in how you apply each one.

As you can see, that extra "Cool" step for the cold peel film adds a bit of time but it's what guarantees precision for those really complex designs.

The constant innovation in these films is a huge reason the DTF market is just exploding. Better tech and more creative uses are pushing DTF into all sorts of industries far beyond just t-shirts. Right now, the market is mostly split between cold peel films, known for their incredible stickiness and detail reproduction, and hot peel films, which are all about faster production and being easier to handle.

This variety gives print shops the power to fine-tune their process for either maximum speed or top-tier quality, depending on what the job calls for. You're now seeing DTF on everything from sportswear to home goods like bedding and curtains, not to mention a whole world of promotional products. You can dive deeper into these industry trends in this comprehensive report on Direct-to-Film printing.

At the end of the day, knowing the difference helps you make smarter choices. If you're pressing a huge order of single-color logos, hot peel is going to save you a ton of time. But if you're making a premium garment with a photorealistic design full of fine lines, the extra patience for a cold peel is absolutely worth it for a flawless result.

Your Step-by-Step Guide to a Perfect Press

Alright, this is where the magic happens—turning that brilliant design and blank shirt into a professional-grade product. Applying a DTF transfer sheet ready to press is pretty straightforward, but the devil is in the details. Following these steps carefully is the difference between a design that pops and one that flops.

I like to think of it like baking a cake. You can have the best ingredients in the world (your garment and transfer), but if your oven temperature or timing is off, you’re not getting the result you want. Your heat press is the oven, and getting those settings just right is your secret to success.

Step 1: Prepare Your Garment

Before you even think about laying down that transfer, you have to prep the fabric. This is a step people often skip, and it shows. Garments, especially cotton, love to soak up moisture from the air, and pressing a design onto a damp shirt is a recipe for disaster. The steam gets in the way and stops the adhesive from doing its job.

To fix this, you need to do a quick pre-press. It's simple.

- Lay your garment flat on the heat press.

- Press it for 5-10 seconds at the same temperature you'll use for the transfer.

- You’ll probably see a little steam rise up. Perfect. That's the moisture escaping.

This not only gets rid of moisture but also irons out any wrinkles, giving you a perfectly smooth canvas. For a deeper look at getting your garments ready, you can explore more techniques for perfect heat transfer shirt printing in our detailed guide.

Step 2: Press Your DTF Transfer

With a dry, wrinkle-free garment waiting, it’s time for the main event. Getting the placement and press settings right is absolutely crucial.

- Set Your Press: Get your heat press dialed in. While every transfer can be a little different, a solid starting point for most cotton and poly blends is 300-325°F (149-163°C) with medium to firm pressure.

- Position the Design: Carefully place the DTF transfer sheet ready to press on the garment, ink-side down. You can use a heat-resistant T-shirt ruler to get it perfectly centered, or just eyeball it if you’ve got a good eye for it.

- Press the Transfer: Cover everything with a Teflon sheet or a piece of parchment paper. This protects both your transfer and the heat platen. Now, press it firmly for 10-15 seconds.

Pro Tip: Don't guess your pressure! Medium pressure should feel like you need to put some muscle into locking it down, but you aren't fighting with it. Too little pressure and the design won't stick; too much and you can actually thin out the ink layer.

Step 3: Master the Peel

This last step is make-or-break, and it all comes down to whether you have a hot peel or a cold peel film. Getting this right is non-negotiable if you want a clean finish.

- Hot Peel: Just like it sounds. As soon as that press pops open, you can confidently grab a corner and peel the film away while the shirt is still piping hot. It’s quick, efficient, and usually leaves a nice matte finish.

- Cold Peel: You have to be patient. Take the garment off the press and let it cool down completely. Seriously, wait until it’s cool to the touch. If you try to peel a cold peel film while it's still warm, you'll pull the design right off with it.

Once the film is off, I always recommend one last step: a post-press. Cover the design with parchment paper and press it again for just 5-7 seconds. This final touch locks the design into the fabric, boosts durability, and gives it a softer feel. Follow these steps, and you’ll be cranking out flawless results every single time.

How to Choose the Right DTF Transfer Supplier

Picking a supplier for your dtf transfer sheets ready to press is a huge decision. It's just as critical as getting your heat press technique down, maybe even more so. The right supplier isn't just a vendor; they're a partner who helps make sure your final products look absolutely killer. But with a sea of options out there, how do you know who to trust?

Think of it like being a chef. You wouldn't settle for subpar ingredients, would you? You need the best stuff, delivered on time, every single time. A great DTF supplier provides transfers with inks that are vibrant and opaque, so they look amazing on any color shirt. They also need a rock-solid adhesive that ensures the design will last. It's not just about finding a good deal; it's about finding a product that makes your brand look good.

Key Qualities of a Top-Tier Supplier

When you're checking out different suppliers, you have to look past the slick website and focus on what really matters: proof of quality and reliability. The best companies are always open and honest about the materials and printers they use.

Here's what you should absolutely demand:

- Vibrant Color and Opacity: Always ask for samples. A quality transfer will have deep, rich colors and a solid white layer underneath that stops the shirt color from bleeding through.

- Realistic Turnaround Times: Everyone loves fast shipping, but consistency is what really counts. A dependable supplier, like Cobra DTF, is upfront about their production schedule and reliably delivers in 1-3 days.

- Responsive Customer Service: Things can go wrong. When they do, you need to be able to reach a real person who can actually fix the problem, not just a chatbot.

A supplier’s quality directly impacts your reputation. Faded colors, peeling designs, and missed deadlines reflect poorly on your business, not theirs. Partnering with a proven, USA-based company eliminates many of these risks.

Understanding Market Needs and Trends

Making the right choice also means knowing what your customers are looking for. The data is clear: most creators prefer buying pre-printed, ready-to-press dtf transfer sheets instead of messing with printing their own. This demand really spikes in July and August as people gear up for festivals, vacations, and other seasonal events. That’s when you absolutely need a supplier who can handle urgent orders without breaking a sweat.

This trend is exactly why finding a phenomenal supplier is so important. You're not just buying a sheet of transfers—you're buying speed, consistency, and peace of mind. This frees you up to do what you do best: design awesome stuff and sell it. Having a local supplier can also be a massive advantage. If you're in a pinch, our guide on finding DTF transfers near you has some great tips for sourcing close to home.

By weighing all these factors—from the ink quality and customer support to how well they align with market demands—you can build a partnership that will truly help your business grow.

Why DTF Is Kicking Off a Revolution in Custom Printing

The explosion of Direct to Film (DTF) printing isn't just another fleeting trend. We're watching a fundamental change in how custom products get made, and it's happening right now. DTF is the driving force behind this shift, bringing professional-level printing within reach for everyone—from a creator in their garage to a rapidly expanding business.

Think about the old way. For years, you needed expensive, complicated screen printing setups to get great results. DTF completely sidesteps those traditional hurdles, throwing the doors wide open for new players.

The numbers don't lie. The global market for DTF printing was already valued at USD 2.72 billion and is on track to hit USD 3.92 billion by 2030. That incredible growth is all thanks to the booming demand for personalized, on-demand apparel. If you want to dive deeper into the data, check out this detailed market report.

Simply put, DTF is leveling the playing field. It gives small businesses the firepower of a massive commercial print shop, letting them compete on quality and speed without needing a six-figure investment.

As this DTF wave continues to build, smart businesses are looking for an edge. A great place to start is understanding how to boost online sales with consumer psychology.

At the end of the day, dtf transfer sheets ready to press aren't just a product. They're a catalyst for innovation, making top-shelf custom printing more accessible than it has ever been.

Got Questions About DTF Transfers? We've Got Answers.

When you're jumping into the world of custom apparel, you're bound to have a few questions. That's a good thing. Getting solid answers is what separates a frustrating experience from creating products you're genuinely proud of.

Let's walk through some of the most common questions we get about dtf transfer sheets ready to press. Think of this as your practical guide to understanding how this all works in the real world—from how long your designs will actually last to the tools you absolutely need for a perfect press every time.

How Long Do DTF Transfers Really Last?

Let's cut right to it: a quality DTF transfer is built to last. When you apply it correctly and follow basic care instructions, that design is going to stick around for 50 to 100 washes. In many cases, the print will actually outlive the t-shirt it's on.

This is a huge step up from many of the older heat transfer methods you might be used to. The ink literally fuses into the fabric, so it stretches and flexes without cracking or peeling. It's a reliable choice for any product that needs to keep looking sharp, wash after wash.

Can I Just Use a Home Iron for Application?

I know it's tempting, but please, step away from the household iron. It's just not going to work. An iron can't provide the two things that are critical for a DTF transfer: consistent, even heat and uniform pressure.

A heat press isn't just a recommendation; it's essential. Using an iron is the number one reason we see transfers fail. The uneven heat and pressure cause peeling and cracking because the adhesive never cures properly. A press creates the perfect environment for a permanent bond.

What Kind of Artwork Is Best for DTF?

This is where DTF really blows other methods out of the water. It handles just about anything you can throw at it. Complex, full-color photos with subtle gradients? No problem. Intricate designs with super-fine lines? It nails those, too. DTF even reproduces transparency effects beautifully.

For the absolute best results, always send your artwork as a high-resolution PNG file with a transparent background. This is key. It ensures we only print your design—no weird white boxes or backgrounds—giving you that clean, professional look you're after.

Ready to create vibrant, long-lasting custom apparel? Cobra DTF provides premium, USA-made DTF transfer sheets with a fast 1-3 day turnaround. Explore our ready to press transfers and get started today!