Finding DTF Transfers Near Me A Local Guide

Share

When you type "dtf transfers near me" into a search bar, what you're really after is a local partner—someone who gets you speed, reliability, and top-notch quality without the drama of international shipping. The smartest move? Almost always, it's sticking with a U.S.-based supplier. They just get it done faster, communication is a breeze, and you can count on the quality in a way overseas options can't promise.

Making this one choice is often the difference between a project that’s on time and on budget, and one that… isn’t.

Finding DTF Transfers Near You The Smart Way

Choosing a local Direct-to-Film (DTF) provider isn't just about saving a few days on shipping; it's a strategic move that directly boosts your efficiency and the quality of your finished products. When you source your transfers from right here in the United States, you neatly sidestep a minefield of common issues—think customs delays, confusing language barriers, and wild shipping estimates that can bring your entire production to a screeching halt.

A domestic partner works on your clock. Got a question about an art file? Need to tweak an order last minute? You'll get a real-time answer instead of waiting a full day for a reply. That kind of responsiveness is gold when you're up against tight deadlines and need to keep your own customers happy.

The Real-World Impact of Going Local

The benefits go way beyond logistics. Partnering with a U.S.-based supplier usually means you're getting transfers made with better, regulated materials. This translates directly to prints that pop with more vibrant color, last longer through wash and wear, and give you the confidence that they meet American safety and quality standards.

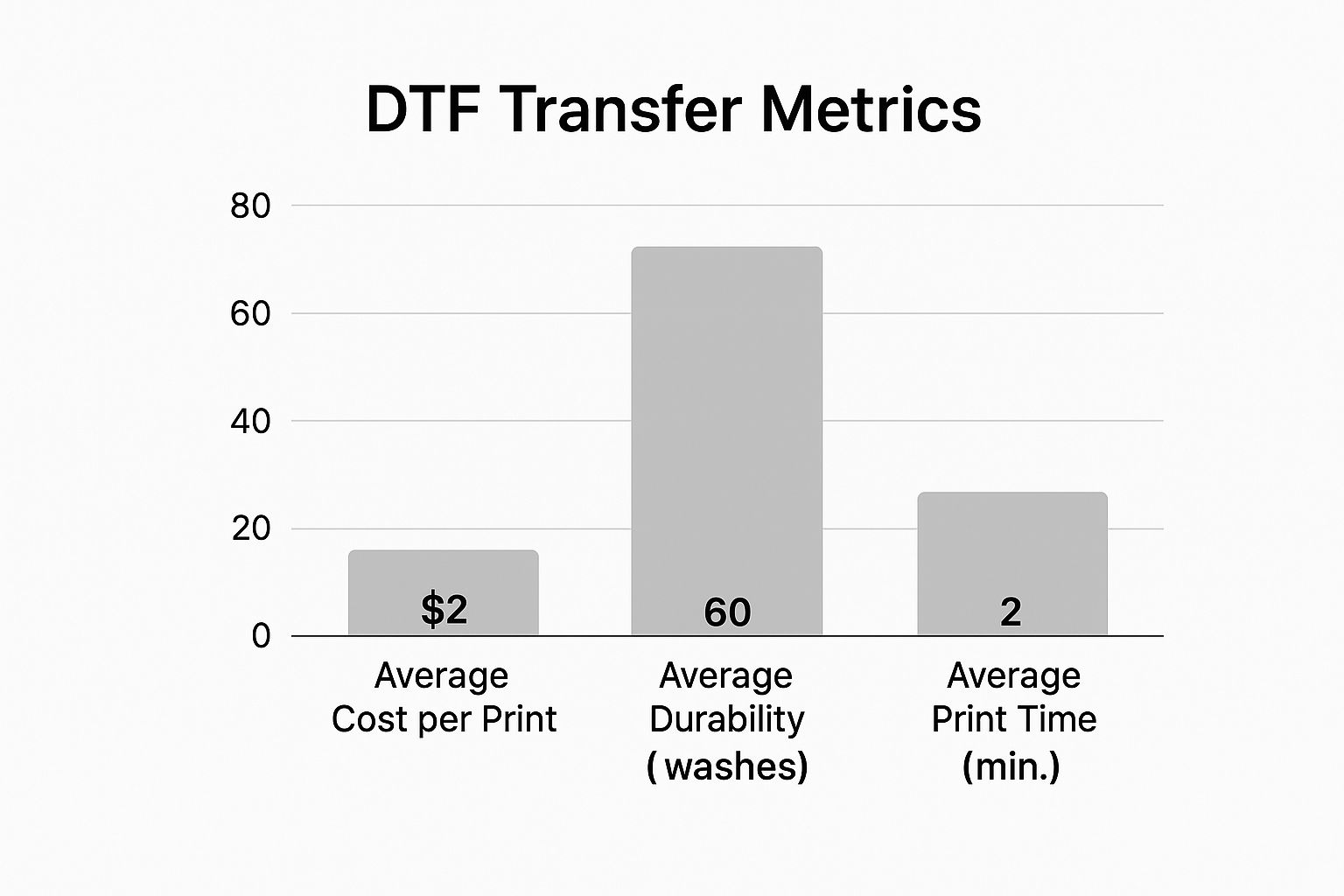

This graphic gives you a quick look at the key performance stats for quality DTF transfers, showing just how efficient and tough this technology is.

As you can see, DTF hits that sweet spot of being affordable while delivering impressive speed and durability. It’s a game-changer for any custom apparel business.

To really spell it out, let’s put local and overseas suppliers side-by-side.

Local US vs Overseas DTF Supplier: A Head-to-Head Comparison

Here’s a practical look at how partnering with a nearby DTF provider stacks up against ordering from an international supplier. The differences are pretty clear.

| Factor | Local US Provider ('Near Me') | Overseas Provider |

|---|---|---|

| Turnaround Time | Usually 1-3 business days for production, plus quick domestic shipping. | Can stretch to weeks due to long production lines, shipping, and customs. |

| Shipping Costs & Fees | Lower, predictable shipping costs. No surprise customs or tariff fees. | Higher shipping costs, plus the risk of unexpected and expensive import duties. |

| Communication | Effortless, real-time communication in the same time zone for fast support. | Communication can be painfully slow because of major time zone differences. |

| Quality Control | Consistent quality you can count on, meeting U.S. standards and regulations. | Quality can be a gamble, with very little you can do about printing mistakes. |

| Supporting Local Economy | Your money supports domestic jobs and strengthens the local economy. | Your investment goes to an international company and economy. |

At the end of the day, finding a supplier for "dtf transfers near me" is about more than just a pin on a map. It’s about forging a reliable partnership that helps your business thrive by consistently delivering a better product, faster and with less friction.

What Exactly Are Direct To Film Transfers

Before you can start searching for the best DTF transfers near me, you need to know what you’re actually buying. Let’s skip the confusing technical talk and use a simple analogy. Think of a DTF transfer like a super high-quality, permanent temporary tattoo, but for fabric.

Instead of printing ink directly onto a shirt, the design is first printed onto a special clear film. This method is fantastic for capturing tiny details and brilliant, vibrant colors—something older printing techniques can struggle with, especially for smaller orders.

This printed film gets coated with a powdered adhesive that sticks only to the ink. After a quick trip through a heater, the ink and adhesive fuse together, creating a transfer that’s ready to go. You just press it onto your garment with a heat press, and the design becomes one with the fabric.

The Magic Behind The Process

The real beauty of DTF is how straightforward it is for you, the creator. You don’t have to deal with messy inks, screens, or complicated equipment. A local DTF provider handles all the technical work, giving you a finished transfer that you can apply in seconds.

Here’s a quick look at what’s happening behind the curtain:

- Printing on Film: Your design is printed onto a special PET film using durable, water-based inks. A layer of white ink goes on last, which acts as a base that makes your colors pop on any garment, light or dark.

- Applying the Adhesive: While the ink is still wet, a fine powder adhesive is sprinkled over the film. Like magic, it sticks only to the inked parts of your design.

- Curing the Transfer: The film then goes through a curing oven, which melts the powder and bonds it directly to the ink. This creates a single, solid, and flexible transfer.

The final product is a crisp, colorful design on a clear sheet, ready for you to press onto pretty much any fabric you can think of.

Why DTF Is A Game Changer For Fabrics

One of the biggest wins for DTF technology is its incredible versatility. Other printing methods can be really picky about the type of fabric they work with, but DTF is the universal key for custom apparel.

DTF transfers aren't just for cotton. They stick beautifully to a huge range of materials, including polyester, cotton/poly blends, nylon, and even treated leather. This opens up a world of possibilities for branding everything from athletic jerseys to rugged workwear.

This flexibility is a huge advantage. It means you don’t have to juggle different printing methods just because you want to sell both cotton tees and polyester hoodies. If you want to get into the nitty-gritty, you can learn more about what Direct-to-Film printing is in our detailed guide.

For small businesses and creators, this adaptability is a massive deal.

Think about it: traditional screen printing requires new screens and different inks for various fabric types, which gets expensive and complicated on small runs. Direct-to-Garment (DTG) printing works best on 100% cotton and often needs a messy pre-treatment spray, especially for dark-colored apparel.

DTF sidesteps all these headaches. It gives you one reliable, high-quality solution that works across your entire product line. That means more freedom to create and less time worrying about technical problems—which is exactly why finding a great local supplier is such a smart move.

The Rise of On-Demand Custom Apparel

The world of custom apparel has been completely turned on its head, and Direct-to-Film (DTF) technology is right at the center of it all. Just a few years back, ordering custom shirts was a headache. You were stuck with high minimums, complicated setup processes, and long waits. Now, a totally different model has taken over, built around speed, flexibility, and making things personal.

This isn't just some passing fad. It’s a direct result of the e-commerce boom and the massive demand from people who want one-of-a-kind products. Just think of all the Etsy shops, indie clothing lines, and small businesses that make their living selling unique designs. They needed a way to create top-notch apparel as orders came in, without having to gamble on hundreds of units that might just sit on a shelf.

DTF technology is the perfect fit for this problem. It knocks down the old barriers that kept smaller creators out of the game, making it incredibly straightforward and affordable to turn a digital design into a real, wearable product.

The Forces Driving DTF Growth

So, what's behind this massive shift? A few key trends are pushing DTF printing into the spotlight, making it the go-to for businesses big and small. The desire for customized gear isn't just for a niche group anymore—it's what everyone expects.

This change is opening up huge opportunities, and the numbers back it up. The global Direct To Film printing market was recently valued at around USD 2.72 billion. That’s a pretty clear sign of serious demand. Even more telling, projections show it climbing to about USD 3.92 billion by 2030, all thanks to businesses scrambling for efficient, on-demand printing. You can explore the full market analysis on GlobeNewswire to dig into the data yourself.

But this growth isn't just about impressive figures; it’s about making things possible. For a local coffee shop, this tech means they can finally sell their own branded merch without a massive upfront cost. For an online artist, it means launching a new t-shirt design is as simple as uploading a file.

Why On-Demand is the New Standard

The old way of doing things—ordering in bulk and hoping for the best—is quickly becoming a thing of the past for many. Businesses today, especially those selling online, have to move fast. Trends can pop up and disappear in a week. The on-demand model that DTF enables gives them some crucial advantages.

- No Inventory Risk: You can print exactly what you need, when you need it. Whether it’s one shirt for a sample or a small run for a weekend market, the financial risk of unsold stock is gone.

- Creative Freedom: Without being tied to large minimum orders, creators can finally experiment. They can test out wilder designs, serve tiny niche markets, and keep their offerings fresh and interesting.

- Speed to Market: A local band can get merch printed for a last-minute gig. A company can order branded polos for a trade show with only a few days to spare. That kind of agility is a massive competitive advantage.

The rise of on-demand printing is less about the technology itself and more about what it unlocks. It gives small businesses and independent creators the kind of production power that used to be reserved for huge corporations, leveling the playing field in a big way.

The very fact that you can now search for DTF transfers near me and get results is a direct outcome of this industry-wide change. Local suppliers are popping up everywhere to meet the need for fast, reliable, and high-quality printing that fits the on-demand economy. It’s a fundamental shift, and it proves DTF isn't just another option—it's the new standard for custom apparel.

Why a US-Based Supplier Is Your Best Bet

Deciding where to get your DTF transfers isn't just about finding a supplier. It's a strategic move that has a real impact on your business—everything from your profit margins and product quality to whether your customers walk away happy.

It’s easy to get drawn in by the seemingly rock-bottom prices from overseas suppliers, but those "deals" often come with hidden costs and headaches that can turn into a total nightmare. When you search for DTF transfers near me and choose a US-based supplier, you’re not just buying a product; you're gaining a reliable partner who understands how you work.

This isn't about flag-waving. It's about smart business. Think faster turnarounds, communication that isn't a struggle, and quality you can actually count on. In the world of custom apparel, these aren't just perks—they're what keep you in the game.

The Speed Advantage That Wins Customers

In this on-demand world, speed is everything. Your customer needs 50 shirts for an event this weekend. Waiting weeks for a shipment to cross an ocean just isn't going to cut it. A local US supplier can often have your order printed and on its way in just a couple of business days.

That kind of agility means you can say "yes" to those last-minute, high-value jobs and hit tight deadlines without breaking a sweat. It's the difference between getting transfers in a week versus the 4-6 week lead time you might see with an international order. That’s how you land a new client instead of watching them go to your competitor down the street.

Eliminating Shipping and Customs Headaches

One of the biggest gambles with overseas suppliers is the black box of international shipping and customs. Maybe your package sails right through. Or, it could get stuck at a port for weeks, tangled in red tape or pulled for a random inspection.

And then there are the surprise fees. That low sticker price can suddenly inflate with tariffs, import duties, and brokerage fees you never planned for.

With a domestic supplier, the whole process is simpler:

- Predictable Costs: The shipping price you're quoted is the price you pay. No nasty surprises.

- No Customs Delays: Your transfers are shipped via trusted carriers like USPS, UPS, or FedEx, without any risk of getting held up at the border.

- Faster Delivery: Standard ground shipping in the US usually takes just 1-5 days. You get your stuff fast, and you know when it’s coming.

Choosing a US-based supplier turns shipping from a major risk into a simple, predictable step in your process. You can stop worrying about tracking containers across the ocean and get back to what you do best: making awesome products.

That reliability is the foundation of a solid supply chain. A US partner gives you the confidence that your materials will show up on time, every time.

The Power of Clear Communication and Quality Control

Ever tried to sort out a problem with a company on the other side of the planet? The endless email chains, the 12-hour response delays, the language barriers—it can turn a small hiccup into a full-blown crisis. When you work with someone in your own country, help is just a phone call away.

If a color looks a little off or you need to tweak a file, you can get it sorted out in minutes, not days. That direct line of communication is priceless for making sure your vision comes to life exactly as you intended. To learn more about this, check out our guide on the benefits of Made in USA suppliers, which goes deeper into why local partnerships just work better.

Plus, US-based manufacturers operate under stricter quality and safety standards. The inks, films, and powders they use are often held to a higher bar, which means you get a final product that's safer, more durable, and more vibrant. This focus on quality means fewer misprints, less wasted material, and a stronger reputation for your brand. When your business is built on delivering great apparel, you can't afford to take chances on quality.

Finding and Vetting the Right Local DTF Partner

So, you see the massive benefits of keeping your DTF supply chain in the U.S. Now, let's get down to the nitty-gritty: how to actually find the best "DTF transfers near me." This is about more than just a quick search—it's about finding a true partner for your business.

Think of it this way: you're not just buying a product. You're entrusting a critical piece of your brand's reputation to someone else. The right supplier delivers more than just printed film; they provide the reliability, expertise, and quality that makes your customers come back for more. You wouldn't hire a key employee without a proper interview, right? The same logic applies here.

Look Beyond the First Page of Google

A simple search is a decent starting point, but don't stop there. The most well-known supplier isn't always the best fit, and some real gems are found by digging a little deeper.

Here’s how to uncover the best local options:

- Scour Their Social Media: Check out potential suppliers on Instagram and Facebook. This is their real-world portfolio. Do the colors pop? Are they showing prints on different types of apparel? It's a fantastic way to get an unfiltered look at their day-to-day quality.

- Tap into Your Local Network: Ask for recommendations in local screen printing forums, small business groups, or artist communities. A referral from someone who has already put a supplier through its paces is worth its weight in gold.

- Read the Real Reviews: Don’t just rely on the glowing testimonials on their homepage. Dig into Google Reviews and other third-party sites to get the full story on their print quality, customer service, and how they handle deadlines.

Putting in this extra legwork now helps you build a solid shortlist of candidates who actually walk the walk.

Your Vetting Checklist: Asking the Right Questions

Once you’ve narrowed it down to a few promising suppliers, it's time to vet them. Go into the conversation armed with smart questions that cut through the sales pitch and reveal their true capabilities. A truly professional operation will be happy to answer these questions with confidence.

Choosing a DTF partner is a make-or-break decision, much like when you're comparing print on demand suppliers. The goal is simple: find a company whose quality and workflow mesh perfectly with yours.

Use this checklist as your guide.

Questions About Their Gear and Materials

- What printers and inks are you running? Not all DTF setups are the same. You want a supplier who invests in commercial-grade printers and top-shelf inks. This is what determines the color accuracy and long-term durability of your transfers.

- Can I get a sample pack? This is non-negotiable. The only way to truly judge quality is to get your hands on the product. A reputable supplier will be eager to send you samples so you can press them, stretch them, and run them through the wash before committing to a big order.

- What are your exact artwork requirements? Ask for their specs on file types (like PNG or AI), resolution (always aim for 300 DPI), and transparency. A supplier with a clear, detailed guide is one who takes quality seriously.

Questions About Their Workflow and Policies

- What’s your real turnaround time? Get a specific answer for production time (e.g., 1-3 business days), and make sure that’s separate from shipping time. This clarity is crucial for managing your own production schedule and keeping your customers happy.

- Do you have a minimum order? A huge perk of DTF is the flexibility to order small batches. Confirm if they have a minimum order quantity (MOQ) or if you can truly order single prints or small gang sheets. This is perfect for testing new designs without a huge investment.

- What happens if there's a problem? Mistakes happen, even with the best printers. What matters is how they fix it. A great partner will have a straightforward, fair policy for reprints or refunds and will stand behind their work, no questions asked.

The Technology Powering Modern DTF Printing

The incredible quality and speed you get from today’s DTF transfers aren’t magic. They're the result of some serious technological leaps forward. Think of a modern DTF printer less like the one in your office and more like a highly specialized, precision-engineered machine built for one job: creating flawless, durable designs with astonishing efficiency.

This technology is the engine behind your search for "DTF transfers near me." When you team up with a local provider, you're tapping into a workflow that’s been fine-tuned for speed and consistency. It allows for the rapid production of even the most complex, multi-color designs without the tedious, screen-by-screen setup of older methods.

These advancements are genuinely reshaping the custom apparel industry. The market tells the story: DTF printer sales alone hit an estimated USD 2.53 billion globally, and they're expected to climb to USD 3.70 billion by 2030. This boom is fueled by brands and creators demanding quicker turnarounds and the ability to print on almost any fabric. You can dig into the numbers yourself in this report on DTF printer market growth.

Speed and Precision Working Together

At the heart of it all, you'll find advanced printheads and automated systems working in perfect sync. High-end DTF printers now run multiple printheads that lay down thousands of microscopic ink droplets per second. This is how you get designs with incredible detail and sharpness, capturing every fine line and subtle gradient.

But it’s not just about precision; it’s about doing it quickly. These systems are tied into workflow software that manages the entire process, from receiving your digital file to the final curing of the adhesive powder.

- Automated Ink Management: A common headache used to be white ink clogging the printheads, causing delays and botched prints. Modern machines automatically circulate the ink to prevent this.

- Precision Film Feeding: The transfer film glides through the machine with robotic accuracy, ensuring perfect alignment and eliminating smudges or misprints.

- Integrated Curing: The best setups combine printing, powdering, and curing into a single, seamless production line. This drastically cuts down on manual labor and production time.

Innovations in Inks and Adhesives

The tech isn't just in the hardware, either. The inks and adhesive powders have seen major improvements. Today’s water-based DTF inks are more vibrant and eco-friendly than ever, formulated to bond powerfully with the adhesive while staying flexible after being pressed onto a shirt.

The result? A transfer that feels softer on the garment, stretches without cracking, and holds its color through dozens of washes. It’s a smarter, more durable, and forward-thinking way to create custom apparel.

This focus on better materials means you get a superior product that looks and feels professional. When you choose a quality local supplier, you’re getting the direct benefit of these ongoing innovations, ensuring your final product is not just good, but exceptional.

Got Questions About Local DTF Transfers? We've Got Answers.

As you get ready to place an order, a few key questions always pop up. Let's walk through the common ones so you can feel totally confident about sourcing DTF transfers near you.

What Do Custom DTF Transfers Typically Cost?

The price tag really depends on the size of your design and the quantity you're ordering, but you'll find local U.S. suppliers are incredibly competitive. You'll usually see pricing broken down per transfer or, more often, by the gang sheet. The gang sheet approach is where you really get your money's worth—you just cram as many designs as you can onto one sheet.

A single, small transfer might only be a few bucks, but the price drops like a rock when you order in bulk. The biggest financial win with a U.S. supplier, though, is sidestepping those killer international shipping fees and surprise customs bills. More often than not, this makes your total domestic order cheaper and way more predictable.

How Do I Get My Artwork Ready for a DTF Order?

The golden rule is high resolution. If you want a print that looks crisp and professional, your file needs to be 300 DPI (dots per inch). It’s also critical that your artwork has a transparent background—unless, of course, a white box is actually part of your design!

For the smoothest process, stick to these standard file formats:

- PNG: This is the crowd favorite because it handles transparency perfectly.

- PSD: If you're working in Adobe Photoshop, layered files are no problem.

- AI: Adobe Illustrator files are ideal for vector art.

- EPS: Another great vector option that keeps everything sharp, no matter the size.

Before you upload anything, do yourself a favor and double-check the supplier's website for their specific art guidelines or templates. Following their rules from the get-go is the easiest way to prevent production hiccups and make sure your prints turn out exactly how you pictured them.

What’s the Typical Turnaround Time for Local Transfers?

This is where finding a solid local provider really shines. Waiting on an overseas package can feel like it takes forever, but most U.S.-based DTF suppliers get orders out the door in just 1-3 business days. Many even offer same-day or rush options if you're in a bind.

Once it ships, you're only looking at another 1-5 days for domestic delivery. That means you can realistically have finished transfers in your hands in under a week. That kind of speed is a game-changer that international suppliers just can't touch, letting you stay nimble and meet your customers' demands fast.

Ready to see what American speed, quality, and reliability look like? At Cobra DTF, we produce top-tier, U.S.-made DTF transfers and offer same-day shipping to get your projects moving. Check out our custom DTF transfers and experience the difference for yourself.