Your Guide to the DTF Printed T Shirt

Share

So, what exactly is a DTF printed t shirt? Think of it as a custom-made shirt created with a cutting-edge technique called Direct-to-Film. Instead of printing directly onto the fabric, this process prints a design onto a special film. That film is then heat-pressed onto the shirt, creating a vibrant, incredibly durable, and flexible graphic that works on almost any material.

Understanding the DTF Printed T Shirt Phenomenon

Ever noticed a t-shirt with a really complex, full-color design that looks incredibly sharp but still feels soft to the touch? You were probably looking at a DTF printed t shirt. This technology has taken the custom apparel world by storm, becoming a go-to for creators and businesses alike. And it’s easy to see why. It hits that sweet spot of quality, versatility, and efficiency that older methods just can't quite nail.

Let's say you want to print a detailed photograph on a dark-colored polyester shirt. With a lot of traditional printing methods, that’s a tough ask—it might be expensive, complicated, or just not possible. This is exactly where DTF printing comes in and changes everything.

How It All Works

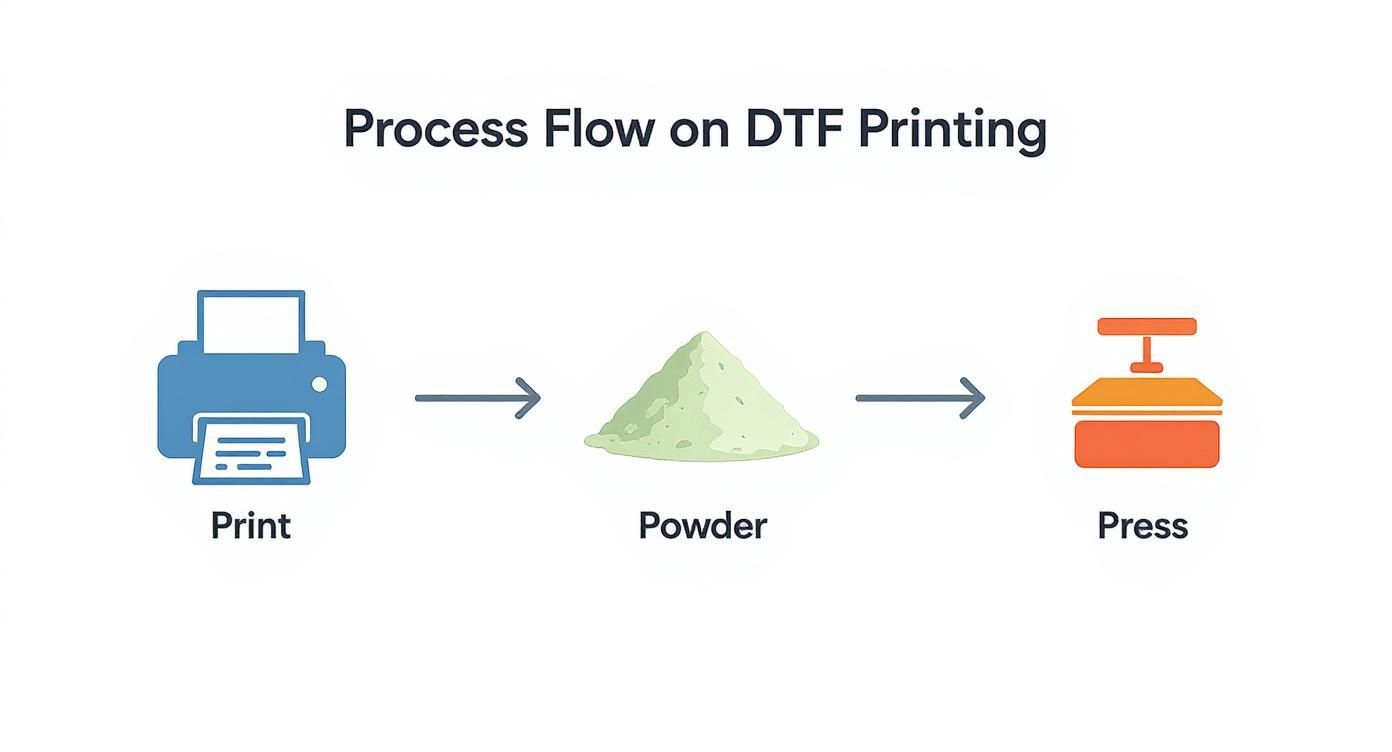

Think of the DTF process like making a super high-quality, professional iron-on that becomes part of the fabric itself, rather than just sitting on top. It all starts with printing your design onto a sheet of special transfer film. Next, a powdered adhesive is sprinkled over the ink and melted, getting the design ready to be applied.

Finally, the film is placed on the t-shirt and pressed with heat. This permanently bonds the design to the garment's fibers. The result is a print that not only looks amazing but is also made to last. It can stretch and move with the fabric without cracking, and the colors stay bright through dozens of washes. That impressive durability is a huge reason why DTF is blowing up.

Why Is Everyone Talking About DTF?

The buzz around DTF printing is well-deserved. It’s not just hype; it’s about solving real-world printing problems that have frustrated people for years. While other methods have limitations—like only working on certain fabrics or light colors—DTF shines where others fall short.

Here’s a quick rundown of what makes it stand out:

- Fabric Freedom: DTF plays nicely with just about everything. Cotton, polyester, nylon, leather, and all sorts of blends are fair game, opening up a world of possibilities for your projects.

- No Color Is Off-Limits: It lays down brilliant, solid colors on any garment, even jet black or bright red, without losing an ounce of detail.

- Complex Designs Are No Problem: Got fine lines, smooth gradients, or photorealistic images? DTF handles them with incredible clarity and precision.

- Great for Any Batch Size: The setup is straightforward, making it just as affordable to print a single custom shirt as it is to run a massive batch.

At its heart, Direct-to-Film printing makes custom apparel accessible to everyone. It tears down the old walls of fabric restrictions, color limitations, and high setup costs, giving anyone the power to create stunning, high-quality designs on almost any piece of clothing.

This incredible flexibility is what's behind its explosive growth. The global impact is undeniable—over 7.2 billion DTF prints were produced in 2024 alone, a massive jump of nearly 30% from the year before. That number really shows how quickly this technology is going from a niche technique to an industry powerhouse.

For a more detailed look at the technology itself, check out our complete guide on what Direct-to-Film printing is.

How Your Design Becomes a Wearable Print

Ever wondered how a digital file transforms into that vibrant, tough-as-nails design on your favorite DTF printed t shirt? It’s a pretty cool process, blending high-tech precision with a bit of hands-on magic. Unlike methods that spray ink right onto the fabric, DTF printing builds the design off the shirt first. This ensures every detail is perfect before it ever meets the cotton.

Think of it like creating a super-advanced temporary tattoo for your shirt—one that becomes a permanent part of the fabric. It's a meticulous journey that guarantees rich colors and crisp lines. Let's walk through it, from pixel to final print.

Step 1: Preparing and Printing the Design

It all starts with your digital art file. This can be anything—a simple one-color logo or a full-blown photographic masterpiece. We load this artwork into special RIP (Raster Image Processing) software, which acts as the brain of the operation, telling the DTF printer precisely how to layer every drop of ink.

The printer then springs to life, but it’s not printing on paper. Instead, it prints your design in reverse onto a sheet of specialized PET (polyethylene terephthalate) film. First, it lays down all the colors (cyan, magenta, yellow, and black). Then, it makes a second pass over the exact same area, printing a solid layer of brilliant white ink on top. This white layer is the secret sauce that makes designs explode with color on any shirt, especially dark ones.

Step 2: Applying the Adhesive Powder

While the ink is still wet on the film, we move to the next crucial step: applying the glue. A fine, granular thermoplastic polyurethane (TPU) adhesive powder is sprinkled over the entire printed surface.

This clever powder only sticks to the wet ink, so the non-printed parts of the film stay clean. We shake off any excess, which means you won't get any stray adhesive specks on your final shirt. This powder is really the unsung hero of DTF; it’s what creates that incredibly strong yet flexible bond between the ink and the fabric.

To get the adhesive ready, the film is passed through a curing oven or placed under a heat press that hovers just above the surface. This melts the powder into a smooth, even film over the ink, creating a single, transfer-ready graphic.

Step 3: The Final Heat Press and Peel

Now it's time for the main event: uniting the design with the t-shirt. The cured DTF transfer is carefully positioned on the garment right where you want it. The whole thing then goes into a heat press.

A specific combination of time, temperature (usually around 300-325°F), and firm, even pressure is applied. This combo melts the adhesive layer for good, fusing the ink directly into the weave of the fabric.

After about 10-15 seconds, the shirt comes out of the press and is set aside to cool down completely. This cooling stage is non-negotiable and is known as a "cold peel." Once it's cool to the touch, the PET film is gently peeled away, revealing a flawless, vibrant, and surprisingly durable print.

The final result is a DTF printed t shirt with a design that feels smooth, stretches without cracking, and is ready to be worn and washed for years to come. For a deeper dive into applying these transfers yourself, you can learn more about the specifics of DTF printing for shirts and how to nail the process every time.

Choosing the Right Print Method for Your Project

So, you've got a killer t-shirt design, but how do you get it onto fabric? The options can feel a bit dizzying—Direct-to-Film (DTF), Direct-to-Garment (DTG), screen printing… where do you even start?

The truth is, there’s no single "best" method. The right choice always boils down to your specific project: how complex is your artwork? How many shirts do you need? What kind of fabric are you printing on? Let's walk through some real-world situations to see where a DTF printed t shirt really shines and how it stacks up against the old-school and new-school competition.

This quick visual breaks down the DTF process. It’s a surprisingly straightforward journey from a digital file to a finished, wearable shirt.

As you can see, DTF cleverly merges the precision of digital printing with the hands-on application of a transfer, giving you the best of both worlds.

When to Choose DTF Printing

Let's imagine you're gearing up for a company fun run. You need 50 shirts, the logo is packed with colors and fine details, and half the team wants classic cotton tees while the other half wants sweat-wicking polyester.

This scenario is tailor-made for DTF. Here’s why:

- Fabric Versatility: DTF doesn’t care if it’s cotton or poly. The print will look just as crisp and vibrant on every single shirt.

- Design Complexity: That full-color, photorealistic logo? No problem. DTF reproduces it perfectly without the headache and cost that screen printing would involve.

- Order Size: For a run of 50 shirts, you skip the steep setup fees that come with screen printing, making DTF a much friendlier option for your budget.

Bottom line: DTF is the king of versatility. It's your go-to when you need brilliant, detailed graphics on a mix of fabrics without being penalized by high setup costs or minimum order demands.

DTF vs Screen Printing: A Practical Look

Screen printing has been the industry standard for decades, and for good reason. If you need 1,000 shirts with a simple, one-color logo for a big event, it’s still the undisputed champ for cost-effectiveness. The per-shirt price plummets at high volumes.

But the game changes the second your design gets more colorful. Each color in screen printing requires its own custom screen, and those setup costs add up fast. A four-color design means four screens, four setups, and a much bigger bill.

A DTF printed t shirt completely sidesteps that issue. Because the design is printed digitally in one go, you can use one color or a hundred—the cost doesn't change.

DTF vs DTG: A Battle of Ink and Fabric

Direct-to-Garment (DTG) is another digital method that works a lot like your desktop inkjet printer. It sprays water-based inks directly into the fibers of the shirt. This gives the print an incredibly soft, breathable feel, especially on light-colored, 100% cotton garments.

But DTG has its limitations. It’s picky about fabrics, performing best on pure cotton and often struggling with polyester. Printing on dark shirts is also a multi-step process involving a pre-treatment spray and a white underbase, which can sometimes mute the final colors.

A DTF print sits on top of the fabric, bonded by a strong adhesive. This is why its colors pop on any garment, from bright white to jet black. A DTG print, on the other hand, becomes part of the fabric itself, which can sometimes lead to less vibrant results on darker materials.

If you want to get deeper into the weeds on these two digital methods, check out our detailed guide comparing DTF vs. DTG printing. It breaks down all the subtle differences in feel, longevity, and cost.

DTF vs DTG vs Screen Printing at a Glance

To help you see the bigger picture, we’ve put together this quick comparison chart. It lines up the three main printing methods so you can easily spot the best fit for your job.

| Feature | DTF (Direct-to-Film) | DTG (Direct-to-Garment) | Screen Printing |

|---|---|---|---|

| Best For | Small to large orders with complex, multi-color designs | One-offs and small runs on 100% cotton | Large bulk orders with simple, limited-color designs |

| Fabric Compatibility | Excellent (Cotton, poly, blends, leather, nylon) | Limited (Best on 100% cotton; struggles with poly) | Good (Works on many fabrics but may need special inks) |

| Print Feel | Soft, flexible, and smooth to the touch | Extremely soft, breathable, no feel on light shirts | Can be thick and heavy, especially with multiple colors |

| Color Vibrancy | Excellent on all fabric colors, including darks | Good on light fabrics, can be less vibrant on darks | Excellent, but each color adds significant cost |

| Durability | High; rated for 50+ washes without cracking or fading | Good, but can fade over time with repeated washing | Very high; extremely long-lasting |

| Cost for Small Orders | Low setup cost, very affordable | No setup cost, affordable for single items | High setup cost, not economical for small batches |

Ultimately, understanding the strengths of each technique is the key. Whether you need one shirt or a thousand, knowing your options ensures you get a final product you'll love without overspending.

What DTF Printing Can Really Do for You

So, we've talked about the nuts and bolts, but what does choosing a DTF printed t-shirt actually mean for your project, your brand, or your hobby? The real magic isn't just in the technology; it's in how it solves the practical headaches that creators and businesses face every day. This isn't just another way to get a design on fabric—it’s a gateway to new creative and financial possibilities.

The advantages go way beyond a single print. DTF gives you incredible flexibility, quality that genuinely lasts, and a smart, cost-effective way to produce gear on your own terms. Let's break down the real-world perks that have made DTF a go-to in the custom apparel world.

Print on Almost Anything

One of the biggest wins for DTF printing is its sheer versatility. Forget being locked into one type of fabric. While other methods can be incredibly picky, DTF plays nice with a massive range of materials. This means you’re no longer limited to just 100% cotton t-shirts.

Imagine you're launching a small clothing line. You want to offer classic cotton tees, but also polyester athletic shirts, nylon windbreakers, and maybe even hats with leather patches. With DTF, you can use the exact same printed transfers for every single one of those items. The quality and color stay consistent across your entire product line. It just works.

This opens up a ton of doors:

- Creative Freedom: Go ahead and print on cotton, polyester, rayon, nylon, silk, leather, and all kinds of blends without switching up your entire process.

- Expand Your Catalog: Easily move from t-shirts to hoodies, tote bags, aprons, and more, all using the same printing setup.

- Consistent Quality: The print looks sharp and feels great no matter the material, so you can trust the final product.

Seriously Stunning Print Quality

A great design deserves to look, well, great. This is where a DTF printed t-shirt really shines. The whole process is designed to deliver ridiculously vibrant colors and crisp, clean details that make people take a second look.

Because the ink is first laid down on a transfer film with a solid white base, the design sits right on top of the fabric instead of soaking in. The result? The colors pop with an intensity you just don't get with other methods, even on black or dark-colored shirts. Fine lines, small text, and even photorealistic pictures come out looking incredibly sharp.

Think of the white ink layer in DTF printing like a painter's primer. It creates a perfect, bright white canvas on the shirt, making sure every color layered on top stays true and brilliant instead of getting muted by the fabric's color.

This means you can print a bright yellow sun on a jet-black t-shirt and it will look just as bright as it does on your screen. No compromises.

Durability That Actually Lasts

Let's be real—a custom shirt is worthless if the design cracks, peels, or fades after a few trips through the laundry. Thankfully, DTF prints are built to handle real life.

The adhesive powder used in the process creates a bond that’s not only super strong but also flexible. This elasticity is key, as it lets the design stretch and move with the fabric without breaking apart. A properly made DTF printed t-shirt can easily stand up to 50 or more washes while keeping its color and integrity.

This kind of lasting quality isn't just a feature; it builds trust with customers and makes sure your designs look awesome for years to come.

Smart Economics for Small Batches and On-Demand

DTF printing is also making custom apparel accessible to everyone by making small orders affordable. This financial advantage is a huge reason for its explosive growth. In fact, market forecasts predict the DTF printing industry will jump from USD 2.72 billion in 2024 to USD 5.18 billion by 2035. This boom is largely fueled by the demand for personalized, small-run printing, as detailed in reports from firms like Spherical Insights.

Older methods like screen printing come with hefty setup costs, which only make sense if you're printing dozens, or even hundreds, of shirts. DTF flips that script. With virtually no setup fees, you can print a single shirt or a small batch of twenty without it costing a fortune. This allows for faster production, less wasted inventory, and the freedom to test new designs without a huge financial risk.

Why Top Creators Trust Cobra DTF

Making a perfect DTF printed t shirt takes more than just a cool design. It demands supplies that work together flawlessly, a truth that seasoned creators and print shops know all too well. They aren't just buying random supplies; they're investing in a complete, unified system. They need a partner who guarantees every ink, film, and powder is engineered to perform, and that's precisely where Cobra DTF comes in.

Choosing a DTF supplier isn't just about finding the lowest price. It's about finding a source you can trust to deliver consistent, professional results with every single print. One bad batch of powder or a cheap roll of film can ruin a whole run, leading to wasted materials, lost time, and unhappy clients. Cobra DTF takes the guesswork out of the equation by offering a meticulously tested ecosystem where every product is designed to work in perfect harmony.

The Power of a Complete Ecosystem

Think of it like baking a cake. You could grab your flour from one store, sugar from another, and eggs from a local farm. They might work, but you can’t be sure of the result. A professional baker, on the other hand, sources ingredients that are proven to work together for a perfect cake every time. That’s the philosophy we live by at Cobra DTF.

Our premium inks, hot-peel films, and specialized adhesive powders aren't just standalone products. They're developed and tested as a team.

- Premium Inks: Our inks are formulated for incredibly vibrant colors and smooth flow, which helps prevent frustrating nozzle clogs and keeps your printer running like a champ.

- High-Performance Films: We engineered our films to grab ink perfectly and then release it cleanly under the heat press. The result? Sharp, detailed transfers, every single time.

- Optimized Powders: Cobra DTF adhesive powder is milled to a specific consistency, creating a bond that’s both strong and flexible. It holds up through dozens of washes without cracking or peeling.

When every component is designed to complement the others, you get predictable, repeatable results. It turns your DTF printer into a reliable production machine you can count on.

Equipment Built for Reliability and Growth

For anyone running a business, equipment downtime is a killer. A printer that needs constant tinkering or a heat press with hot spots can grind your entire operation to a halt. We get it. That’s why Cobra DTF equipment is built to be robust and reliable, whether you're just starting out or running a full-scale print shop.

Our machines are true workhorses, built for consistent output day in and day out. We also focus on making them user-friendly, so newcomers can get up and running quickly while seasoned pros can maximize their workflow. This focus on dependable hardware means you can spend more time printing and less time troubleshooting.

"Success in DTF printing is built on consistency. When your inks, films, and powders are all pulling in the same direction, you eliminate variables and can focus on what really matters—creating amazing products for your customers."

Unmatched Support and Education

At the end of the day, what truly makes Cobra DTF different is our commitment to your success. Providing the best supplies and equipment is only half the job. The other half is giving you the knowledge and support you need to master the art of making a fantastic DTF printed t shirt.

From detailed setup guides and video tutorials to a responsive customer service team staffed by real experts, we're here to help you get it right. We’ve been there, we understand the learning curve, and our team is ready to share practical advice and best practices. We don’t just want to sell you products; we want to help you become a skilled creator, fully confident in your ability to produce top-tier custom apparel.

Where DTF Printing Is Headed Next

The world of custom apparel never sits still, and the technology behind the dtf printed t shirt is setting the pace for what's next. This isn't just another printing trend; it's a fundamental shift that lines up perfectly with how people want to buy and create things today—unique, personalized, and on-demand.

The numbers tell a pretty clear story. The global DTF market was valued at around USD 2.72 billion in 2024, and experts predict it will jump to USD 3.92 billion by 2030. That kind of growth is directly tied to the explosion in demand for personalized gear and the fact that DTF makes it incredibly cost-effective. If you're curious about the nitty-gritty details, you can dive into the full industry analysis on Grandview Research.

A Perfect Match for the Creator Economy

For anyone in the creator economy, DTF printing is a massive unlock. Not long ago, launching a merch line was a huge headache. You had to sink a ton of money into a big inventory run, figure out all the logistics, and then cross your fingers that it would sell. DTF completely flips that script.

Now, artists, YouTubers, and small businesses can create and sell custom apparel with virtually no risk. Since DTF is built for on-demand printing, you can make one shirt just as easily as you can make a hundred. This gives creators the freedom to experiment with new designs, offer limited-edition drops, and grow their brand without a warehouse packed with unsold t-shirts. It's simply a smarter, more accessible way to bring ideas to market.

What's on the Horizon?

The technology itself isn't standing still, either. The future of DTF is all about making the process faster, more automated, and better for the planet. We're already seeing some exciting developments taking shape:

- Smarter Automation: Expect to see more all-in-one systems that handle everything from powdering and curing to cutting the final transfer. This means less manual work and much faster turnaround times.

- Blazing-Fast Printers: The next wave of printers will boost production speeds without compromising the sharp details and brilliant colors that make DTF so popular.

- Greener Materials: Sustainability is a huge focus. Innovators are working on better water-based inks, biodegradable films, and curing ovens that use far less energy.

At its heart, the promise of DTF technology has always been about making top-quality custom printing easier and more flexible for everyone. The innovations coming down the pipeline will only make that promise stronger.

Choosing DTF isn't just about picking a printing method for today. It's about aligning your brand with a technology built for a world that demands personalization, speed, and smarter manufacturing.

Your Top Questions About DTF T-Shirts, Answered

Jumping into DTF printing is exciting, but it's smart to have a few questions. We get it. Let's clear up some of the most common things people ask so you can feel totally confident about choosing DTF printed t shirts.

How Long Does a DTF Printed T-Shirt Last?

One of the best things about a quality DTF print is its incredible durability. You can expect it to handle 50+ washes without cracking or fading. In many cases, the print will actually outlast the t-shirt itself. This staying power comes from the way the special inks and adhesive bond directly into the fabric's fibers.

To get the most life out of your shirt, just follow a couple of simple rules: wash it inside-out in cold water and tumble dry on low. Or better yet, hang it to air dry.

What Does a DTF Print Feel Like on a Shirt?

While you can feel the print on the fabric, it’s known for having a "soft hand." It's a world away from those thick, stiff vinyl transfers you might have felt before.

The print is lightweight and flexible, designed to stretch and move right along with the shirt, making it super comfortable for all-day wear. It’s slightly more raised than a Direct-to-Garment (DTG) print, but it’s much thinner and more pliable than a heavy layer of screen printing ink.

Think of it like this: DTF gives you the soft, premium feel of a screen print transfer combined with the unlimited colors and sharp detail you get from a high-end digital print. It’s the perfect sweet spot between durability and comfort.

Is DTF Printing an Eco-Friendly Choice?

When you stack it up against older methods, DTF printing is definitely a more environmentally sound choice. The process uses non-toxic, water-based inks and creates almost no waste, since the design is printed exactly as needed onto the film.

This is a huge improvement over traditional screen printing, which requires tons of water and harsh chemicals for creating and cleaning screens. That makes DTF a much more sustainable option for anyone creating custom apparel today.

As you get your designs ready, you'll also need great-looking product photos. If you're looking for a fast and easy way to create professional shots for your online store, a tool like an AI product photo generator can help you craft stunning visuals without a complicated photoshoot.

Ready to create vibrant, long-lasting custom apparel with a partner you can trust? Cobra DTF offers premium, USA-made supplies and expert support to bring your vision to life. Explore our DTF solutions today!