Find the Best Machine for Printing T Shirts

Share

Let's be real: there's no single "best" machine for printing T-shirts. The right choice for you depends entirely on what you want to create and who you're selling to.

For those incredibly detailed, full-color designs on cotton that feel soft to the touch, nothing beats a Direct-to-Garment (DTG) printer. If you need vibrant prints that pop on any fabric, Direct-to-Film (DTF) is the most versatile player in the game. And for big runs of simpler designs, old-school screen printing still reigns supreme for its unbeatable cost per shirt.

Choosing Your T-Shirt Printing Machine

This guide is designed to cut through the noise and get into the nitty-gritty of what makes each technology tick. We’ll kick things off with a quick-glance comparison to help you immediately see which machine fits your business model, budget, and quality standards.

Think of this as a starting point. Picking the right equipment isn't about finding a magic bullet; it's about matching a machine's strengths to your specific creative and business goals.

A Quick Look at Your Options

Before we dive deep, let's get a feel for the landscape. Every printing method comes with its own set of trade-offs in cost, quality, and what materials it can handle.

For instance, the best machine for printing t shirts for a small Etsy shop specializing in one-off, intricate cotton designs (DTG) is worlds apart from the ideal setup for a local shop cranking out team jerseys for the whole league (Screen Printing). This first overview will give you that high-level snapshot to get you oriented.

T-Shirt Printing Machine Technology At a Glance

Here’s a simplified breakdown to help you compare the main technologies at a glance. Think of it as your cheat sheet for understanding the core differences.

| Technology | Best For | Initial Cost | Print Feel | Best Feature |

|---|---|---|---|---|

| DTG Printer | Photorealistic designs on cotton | High ($15k+) | Soft, breathable | Unmatched detail & color |

| DTF Printer | Any fabric, any color | Medium-High ($3k+) | Flexible, slightly raised | Ultimate versatility |

| Screen Printing | High-volume, simple designs | Low-High ($500+) | Durable, slightly thick | Lowest cost per print at scale |

| Heat Press Vinyl | Simple logos, text, numbers | Low ($300+) | Layered, can be stiff | Specialty finishes (glitter, puff) |

| Sublimation | All-over prints on polyester | Low-Medium ($500+) | None (infused into fabric) | Permanent, vibrant prints |

This table should make it clear that your business model is the most important factor in this decision.

Key Considerations for Your Business

Your choice of machine will directly shape your day-to-day workflow, your profit margins, and the final product you hand over to your customers. It’s a big deal.

Take a hard look at your primary business model:

- On-Demand Customization: If your bread and butter is selling unique, one-off designs with tons of color, a DTG or DTF printer gives you the flexibility you need without the painful setup times of other methods.

- Bulk Production: For businesses focused on large batches of the same design—think company events or school uniforms—screen printing is the most cost-effective path. Your cost-per-shirt drops dramatically as your volume climbs.

- Material Diversity: Planning to print on more than just cotton tees? If your brand includes polyester athletic wear, hats, or tote bags, a DTF or sublimation setup will give you far more freedom to expand your product line.

The most common mistake I see new businesses make is buying a machine that doesn't match their actual production volume. A high-end DTG printer can quickly become a $20,000 paperweight if you're only getting a few orders a week. On the flip side, a manual screen printing press will turn into a serious bottleneck the moment your orders start to surge.

At the end of the day, the best T-shirt printing machine is the one that helps your business grow without getting in the way. By understanding these core differences from the get-go, you can avoid costly mistakes and choose a technology that will be the foundation of your success, not a limitation.

Getting to Know the Core Printing Technologies

Before you can even think about which t-shirt printing machine to buy, you need a solid grasp of the technologies themselves. Each one works differently, uses specific materials, and produces a unique look and feel. Getting this right from the start is the key to a smart investment.

The demand for custom apparel isn't slowing down, and the technology is evolving right alongside it. In fact, the global market for textile printing machinery is expected to hit nearly $13.99 billion by 2025—a massive leap from $9.2 billion in 2017. This boom is all about giving people more options, faster.

Direct to Garment (DTG) Printing

Think of a DTG printer as a high-tech inkjet printer, but for t-shirts instead of paper. The machine sprays specialized water-based inks directly onto the fabric, allowing them to soak into the fibers.

This is the go-to method for photorealistic images with millions of colors and intricate details. Because the ink becomes part of the shirt, the final print is incredibly soft and breathable—you can barely feel it. The catch? DTG performs best on 100% cotton and requires a pre-treatment spray to make sure the ink sets properly.

Direct to Film (DTF) Printing

DTF printing has completely shaken up the industry with its versatility. The process starts by printing a design onto a special transfer film. While the ink is still wet, a powdered adhesive is applied to the back and then cured with heat.

Once cured, you have a ready-to-press transfer that can be applied to almost any fabric imaginable—cotton, polyester, blends, leather, you name it—and on any color. DTF prints are known for their stunning vibrancy and durability. They sit on top of the fabric, giving them a flexible, slightly raised feel. If you want to get into the weeds, you can explore the nuances of different t-shirt printing techniques in our deep-dive guide.

The Bottom Line: DTG prints into the fabric, which is why it feels so soft and works best on cotton. DTF creates a transfer that is pressed onto the fabric, which is what gives it incredible versatility. This single difference is often the deciding factor.

Screen Printing

Screen printing is the OG of the t-shirt world. It's a classic, time-tested method where you push ink through a mesh stencil (the "screen") directly onto the garment. The trick is that you need a separate screen for every single color in your design.

The setup can be a real grind, but once you're ready to go, you can crank out hundreds or even thousands of shirts at a ridiculously low cost per piece. This makes screen printing the undisputed king for large-volume jobs with simple, bold graphics.

Heat Press Vinyl (HTV) and Sublimation

People often lump these two together, but they couldn't be more different in how they work and what they do.

-

Heat Press Vinyl (HTV): With HTV, you use a plotter to cut designs out of colored vinyl sheets. You then "weed" away the excess vinyl and use a heat press to apply the design to the shirt. It’s a fantastic choice for names, numbers, and simple logos, and it opens the door to cool finishes like glitter, metallic, and puff.

-

Sublimation: This is where the magic happens. Sublimation uses special dye that turns into a gas when heated, permanently embedding itself into the fibers of polyester fabrics. The result is a print that has zero feel and will never crack, peel, or fade. It's the perfect match for all-over prints on light-colored sportswear.

Choosing the right tool for the job is a universal rule in printing. Just like we pick a specific technology for t-shirts, other industries have their own specialized methods, like printing on specialized materials like Coroplast. Each technology has a role to play, defined by the material it's built for.

A Detailed Look at T-Shirt Printing Machines

Picking the right t-shirt printing machine is about more than just a quick pros and cons list. It’s about digging into how each technology actually performs in the real world, stacking them up against the things that will make or break your business—print quality, what fabrics you can use, how much it costs to get started, and how fast you can get orders out the door.

Let's break down the head-to-head matchups. This is where you'll see which machine truly shines for certain jobs and where it might fall flat for others. By the end, you'll have a much clearer picture of which one fits your specific goals.

Print Quality and Feel

The way a print looks and feels is everything. It's the first thing your customer notices and is a direct reflection of your brand's quality.

When it comes to soft, breathable prints on cotton, Direct-to-Garment (DTG) is the undisputed champion. The water-based ink soaks right into the fabric fibers, so the design feels like it's a part of the shirt. This method is incredible for reproducing photos, complex details, and smooth color gradients with amazing precision.

Direct-to-Film (DTF), on the other hand, creates a print that sits on top of the fabric. The result is a stunningly vibrant and sharp image with a flexible feel that has a slight texture. While not quite as breathable as DTG, the big win for DTF is its incredible color pop, especially on dark shirts, all thanks to a solid white ink underbase.

- Screen Printing: This classic method is known for its thick, tough, and super-vibrant prints using plastisol inks. You can definitely feel the raised design, which is often exactly the look people want for bold, graphic-heavy apparel.

- Sublimation: With sublimation, the print has zero feel. Seriously. The dye becomes a gas and fuses directly with polyester fibers, so the design is permanently part of the fabric. It will never crack, peel, or fade.

- Heat Press Vinyl (HTV): This technique gives you the thickest layer, since you're literally pressing a sheet of vinyl onto the shirt. It can feel a bit stiff or rubbery, but it’s the go-to for unique textures like glitter, puff, and shiny metallic finishes.

Fabric and Material Compatibility

Your choice of machine directly dictates what you can sell. Knowing which fabrics play nicely with each technology is a deal-breaker.

DTF is the clear winner when it comes to versatility. Because it uses a transfer, it works perfectly on a massive range of materials—cotton, polyester, rayon, nylon, leather, and all sorts of tricky blends. This makes a DTF printer the best option if you want to offer a wide variety of products. Our guide on the best DTF printer for a small business dives deeper into why this flexibility is a game-changer for new shops.

DTG, in contrast, is a specialist. It needs 100% cotton or at least a high-cotton blend to achieve those premium, soft-to-the-touch results. If you try to print on polyester with a standard DTG setup, you'll end up with faded colors and ink that just won't stick.

Key Differentiator: The core trade-off is simple: DTG gives you that amazing soft feel on cotton, while DTF gives you the power to print on almost anything. Your decision here should be driven entirely by your product vision and who you're selling to.

Sublimation is even more specific, working only on light-colored, 100% polyester garments or hard goods with a special polymer coating. Screen printing and HTV are also quite flexible, handling both cotton and polyester well, though you might need to switch up your inks or vinyl for different materials.

Startup Costs vs. Per-Print Expenses

Your financial commitment isn't just the price tag on the machine; it's also the ongoing cost of supplies for every shirt you print. A cheap machine can sometimes mean expensive prints down the road.

Screen printing has the widest range of startup costs. You can get a simple manual press for under $1,000, but a professional multi-color automatic press can easily run you over $30,000. The real magic of screen printing is its incredibly low per-print cost on large runs, where the price of ink per shirt becomes tiny.

DTG printers are a serious upfront investment, generally starting around $15,000 and going up from there. The per-print cost is moderate, which is perfect for one-off custom orders where you can charge a premium. This on-demand model is why the global DTG market is projected to skyrocket from $3.2 billion in 2025 to $9.1 billion by 2035.

DTF printers and heat presses offer a much more manageable entry point, with solid setups available in the $3,000 to $8,000 range. The ongoing costs for film, powder, and ink are also quite reasonable, hitting a sweet spot for small to medium-sized businesses.

Feature-by-Feature Technology Breakdown

To make things even clearer, let's put these technologies side-by-side. This table breaks down the key features that matter most, from the initial investment to what kind of jobs each machine is built for.

| Feature | DTG | DTF | Screen Printing | Heat Press Vinyl | Sublimation |

|---|---|---|---|---|---|

| Initial Investment | High ($15,000+) | Medium ($3,000 - $8,000) | Low to Very High ($500+) | Low ($300+) | Low to Medium ($500+) |

| Best For Volume | Low (1-50 pieces) | Low to Medium | High (100+ pieces) | Low (1-20 pieces) | Low to Medium |

| Print Feel | Very Soft, No Feel | Flexible, Slight Feel | Thick, Raised Feel | Thickest, Rubbery | Zero Feel, Infused |

| Color Vibrancy | Excellent | Exceptional | Very Good | Excellent | Excellent |

| Fabric Compatibility | Cotton & Blends | Nearly Any Fabric | Cotton & Polyester | Cotton & Polyester | 100% Polyester Only |

| Detail/Complexity | Photorealistic | Very High Detail | Good (for vectors) | Simple Shapes | Photorealistic |

Ultimately, the best machine for printing t-shirts is the one that lines up with your business plan. Buying a high-capacity machine when you're only doing small custom jobs is a waste of money, just as trying to print a 500-shirt order on a machine built for one-offs will be a nightmare. This comparison should help you choose the right path forward.

Finding the Right Machine for Your Business Model

The "best" machine for printing t-shirts isn't about the one with the most bells and whistles. It's about finding the perfect fit for your business. A top-of-the-line printer is just an expensive paperweight if its speed, costs, and capabilities don't align with how you actually make money. Let's move past the spec sheets and look at how these machines perform in the real world.

We'll break it down by looking at three common types of entrepreneurs: the on-demand artist, the local print shop, and the high-volume merchandiser. By seeing what they need to succeed, you can get a much clearer picture of which machine would work for you.

The On-Demand Custom Creator (The "Etsy Seller")

This is the creative entrepreneur who lives and breathes unique, one-off designs. Their entire business is built on high-variety, low-volume orders that come in one at a time. They absolutely need a machine that can reproduce photorealistic images and complex graphics without the headache of a long and costly setup for every single order.

A real-world scenario: Imagine an artist selling tees with their incredibly detailed digital paintings. Every order is different, and their customers expect those vibrant colors to pop on a soft, high-quality cotton shirt. Wasting time and materials to set up for just one shirt would completely sink their profit margin.

For this kind of business, two options make sense:

- DTG (Direct-to-Garment): This is the gold standard if you're laser-focused on 100% cotton apparel. Nothing beats the soft-hand feel and stunning detail DTG provides, making it ideal for art-driven brands.

- DTF (Direct-to-Film): This is the workhorse. A DTF printer gives the seller freedom to branch out beyond cotton shirts to polyester blends, hoodies, hats, and tote bags, all while delivering a brilliant, long-lasting finish.

Our Takeaway: For most online sellers, a DTF printer is the smarter investment. The sheer flexibility to print on almost any fabric opens up way more product avenues, and the print quality is fantastic for the kind of detailed, full-color work that sells online.

The Versatile Local Print Shop

The neighborhood print shop has to be a jack-of-all-trades. One day it's ten custom shirts for a bachelorette party; the next, it's a 200-shirt order for the town's annual 5K race. The key here is having the right tools to pivot between small, intricate jobs and medium-sized runs without missing a beat.

A real-world scenario: This shop is the go-to for local schools, small businesses, and event organizers. They need to be able to print a full-color logo on a handful of polos just as easily as they can print single-color text on 150 event tees. Their reputation is built on saying "yes" to almost any request that walks through the door.

To make this model work, you really need a hybrid setup:

- A DTF Printer for Custom Work: This is non-negotiable for handling those low-volume, full-color orders. DTF gives you the speed and quality to knock out custom jobs profitably, sidestepping the laborious setup of screen printing.

- A Manual Screen Printing Press for Bulk Orders: When the quantity gets higher, screen printing is your money-maker. It keeps the cost-per-print incredibly low on orders of 50 shirts or more, allowing you to offer competitive pricing for those bigger jobs.

With these two machines, a local shop is armed to handle just about any customer request that comes their way.

The High-Volume Merchandiser

This is the world of bulk production. Think clothing brands, promotional product companies, and contract printers. Here, the game is all about two things: minimizing the cost-per-unit and maximizing throughput. Production speed and scalability are far more important than one-off design complexity.

A real-world scenario: A merchandise company lands a contract to print 5,000 t-shirts with a two-color logo for a band's national tour. The only way to make a profit is to churn these out as fast and as cheaply as possible, while still ensuring the print is durable enough to survive a mosh pit.

Our Takeaway: An automatic screen printing press is the only tool for this job. The upfront investment is significant, no doubt. But its ability to print hundreds of shirts per hour makes the cost-per-shirt laughably low at this scale, which is essential for winning large contracts.

The enduring efficiency of screen printing for large runs is why the global market for these machines is projected to hit around $245 million by 2025. This growth, especially with the rise of e-commerce, shows just how vital this technology remains. You can dive deeper into the T-shirt screen printing market's future on Archive Market Research.

Using DTF Transfers Without Buying a Printer

Let's be real: dropping thousands of dollars on printing equipment is a huge barrier for anyone just starting out. The price tag is high enough, but then you factor in the learning curve and all the maintenance, and it's easy to see why so many great t-shirt ideas never get off the ground. But what if you could sidestep that entire investment?

There's a smarter, more practical way to get into the game. You can tap into professional-grade printing with just one piece of equipment: a simple heat press. By using pre-made Direct-to-Film (DTF) transfers, you completely eliminate the need for a printer, a powder shaker, or a curing oven. This approach separates the technical headaches of printing from your actual business, letting you focus on what you do best—creating killer designs and selling them.

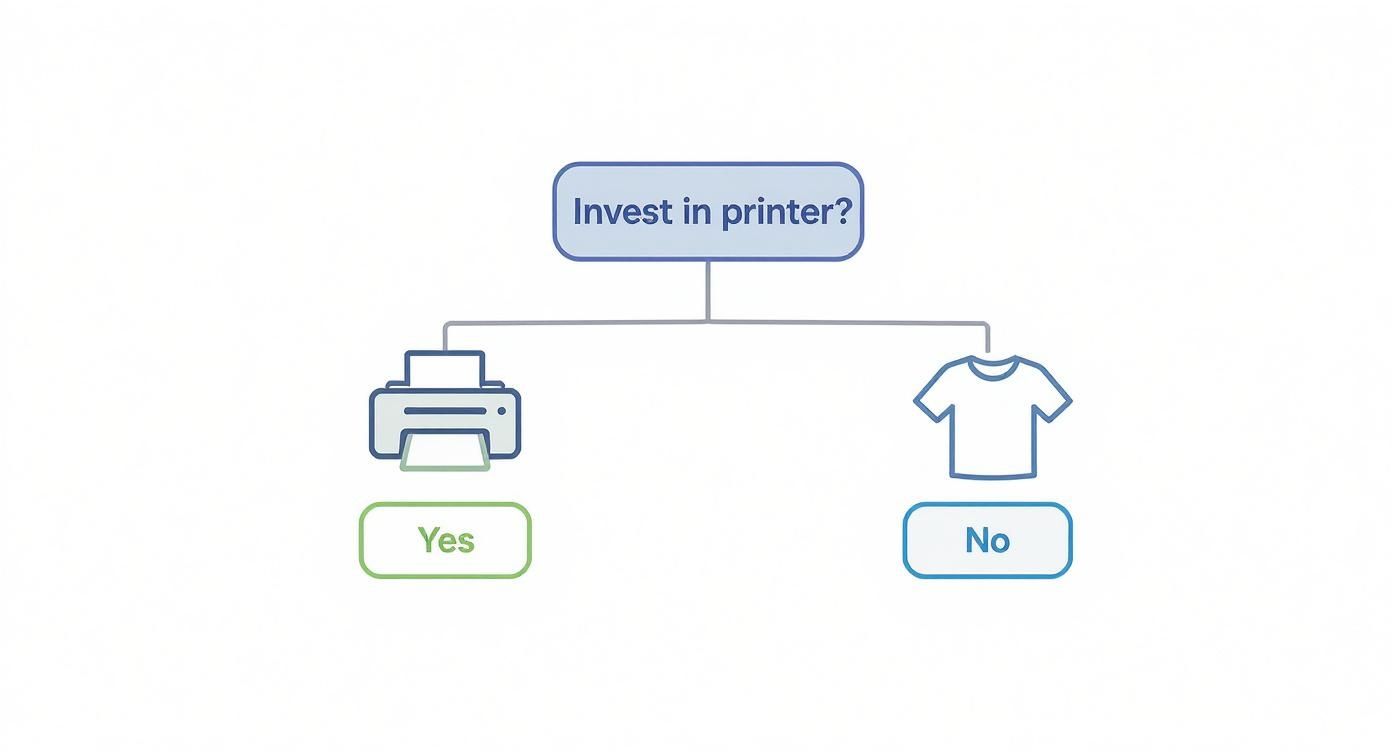

This decision tree breaks down the two main paths you can take when starting a t-shirt business, depending on whether you're ready to invest in your own equipment.

As you can see, saying "no" to buying a machine right away doesn't stop your business. It just puts you on a simpler, more streamlined path that centers around using transfers.

The Business Case for a Printer-Free Start

The perks of going this route are massive, especially for a new brand. The most obvious one is the huge drop in startup costs. Instead of shelling out $3,000+ for a full DTF setup, your only real equipment cost is a quality heat press, which you can find for just a few hundred bucks. That alone dramatically lowers your financial risk.

On top of that, you get to skip all the machine maintenance. DTF printers need constant attention—cleaning routines, ink management—to keep them from clogging and to maintain print quality. When you just order transfers, you pass all those technical chores off to someone else. That means no time wasted troubleshooting a finicky machine and more time finding and delighting customers.

The printer-free model is the ultimate way to test the market. You can order small batches of different designs to see what actually sells without getting stuck with a mountain of unsold shirts or a machine gathering dust. It's a flexible, low-risk strategy for proving your concept and building real momentum.

How Custom DTF Transfers Work

The process couldn't be easier. You just upload your print-ready designs to a transfer supplier's website, pick your size and quantity, and hit "order." The transfers show up at your doorstep already printed, powdered, cured, and ready to go.

Your job becomes incredibly simple:

- Place the Transfer: Just position the DTF transfer film on your blank t-shirt.

- Press with Heat: Use your heat press for about 15 seconds, following the supplier's instructions.

- Peel and Finish: Let it cool for a moment, peel the film back, and you're left with a vibrant, tough, professional-looking print.

This method gives you the exact same full-color, high-quality results as an in-house DTF machine, but without any of the operational baggage. If you want to dive deeper, you can learn more about how to get started with custom DTF transfers that are ready to press in our detailed guide. It’s the perfect starting point for building a brand before you commit serious capital to equipment.

Making the Final Call: Your T-Shirt Printer Checklist

Alright, let's cut through the noise. Choosing the right T-shirt printing machine isn't about finding the "best" one—it's about finding the best one for you. It all comes down to a clear, honest look at your own situation.

Walk through this checklist. Answering these questions honestly will give you the clarity you need to invest with confidence and avoid a costly mistake.

Money Talks: Budget and Financial Planning

Your starting capital is the first and most practical hurdle. You need a realistic budget that goes beyond the price of the machine itself. Remember to account for inks, films, screens, software, and a starting inventory of blank shirts.

- What’s your absolute max for the initial investment? If you're working with less than $1,000, you should be looking at a heat press vinyl setup or simply starting with pre-made DTF transfers. Once your budget pushes past $15,000, high-quality DTG printers become a real possibility.

- Have you priced out the ongoing costs? Don't get tripped up by a cheap printer with expensive supplies. You have to calculate your cost per print—including ink and other consumables—because that's what will eat into your profits day after day.

- Should you consider financing? For the big-ticket items like an automatic screen printing press or a commercial-grade DTG machine, exploring equipment financing can be a smart move. It helps you hold onto your cash for other business needs.

Reality Check: Production and Workspace

The machine has to fit into your physical space and your daily life. It's easy to get excited about specs and forget the practical realities of operating and maintaining this equipment.

One of the most common rookie mistakes is completely forgetting about ventilation. Screen printing wash-out booths and even some DTF powder stations create fumes. You can't just stick them in the corner of a bedroom; you need a dedicated, properly ventilated workspace.

Think through these real-world logistics:

- How much room do you actually have? Get out a tape measure. A simple heat press setup might fit on a sturdy desk, but an automatic screen printing press will eat up the space of a small car.

- What’s your real production volume going to be? Be honest with yourself. Are you printing ten shirts a week for your new Etsy shop, or are you trying to land a 500-shirt order for a local marathon? The answer points you directly toward the on-demand flexibility of DTF or the high-volume muscle of screen printing.

- How much time can you commit to maintenance? This is non-negotiable. DTG and DTF printers demand daily and weekly cleaning. If you can't commit to that routine, performance will drop, heads will clog, and you'll have an expensive paperweight on your hands. Screen printing is no different—it requires a thorough, messy cleanup after every single job.

By thinking through these core factors—your budget, space, expected volume, and maintenance tolerance—you can look past the marketing hype. This checklist is designed to help you define what you truly need, ensuring the machine you choose becomes a powerful asset for your business, not a constant headache.

Frequently Asked Questions

You've got the big picture, but now it's time to iron out the details. Here are some of the most common questions we hear from people trying to pick the right T-shirt printing setup.

What's the Easiest T-Shirt Printing Machine for a Beginner?

If you're just starting out, a heat press vinyl (HTV) setup is tough to beat for simplicity. You'll need a vinyl cutter and a heat press, but the process itself—cut, weed, and press—is incredibly straightforward. You get to skip the mess and maintenance that comes with liquid inks in DTG or DTF printers.

But what if you want full-color prints without a steep learning curve? In that case, grabbing some pre-made Cobra DTF transfers and a heat press is even easier. This lets you bypass the printing step altogether and just focus on pressing high-quality designs onto your shirts.

How Much Does It Really Cost to Start a T-Shirt Printing Business?

This is the big one, and the answer really depends on your ambition. You can get your foot in the door with a basic heat press and vinyl cutter for as little as $500. For a more professional operation that can handle full-color, a Direct-to-Film (DTF) printer is a great next step, with starter bundles usually running between $3,000 and $8,000.

If you're aiming for a serious commercial setup, a Direct-to-Garment (DTG) printer can set you back $15,000 or more. And for true high-volume production, an automatic screen printing press can easily top $30,000. Don't forget to factor in your first round of supplies like inks, blank shirts, and software, too.

Can I Print on Dark T-Shirts with Any Machine?

Not a chance. Printing vibrant colors on dark fabrics requires a special trick: a layer of white ink that acts as a base for the colors to pop. Without it, your colors will just sink into the dark material and look muddy.

The Takeaway: DTF and DTG printers were built for this. They excel at laying down that crucial white underbase, making them perfect for black or dark-colored apparel. Screen printing is also a classic choice for darks, but sublimation is a no-go—it has no white ink and only works on light-colored polyester.

What's the Deal with Ongoing Machine Maintenance?

Maintenance is a huge factor you can't afford to ignore. DTG and DTF printers are the most demanding here. They need daily, sometimes even weekly, attention to keep the ink lines and printheads from clogging. This isn't optional; it's essential for keeping your machine alive.

Screen printing gear needs a solid cleanup after every print run—you'll be washing ink out of screens, squeegees, and spatulas. On the other end of the spectrum, heat presses and vinyl cutters are about as low-maintenance as it gets, usually just needing a wipe-down and a new blade every now and then.