How to Price Custom Shirts: Boost Your T-Shirt Business

Share

Pricing a custom shirt isn't just pulling a number out of thin air. It’s a straightforward formula, really: figure out what it costs you to make one shirt, add a profit margin that makes it worthwhile, and then peek at what your competitors are doing to make sure you’re in the right ballpark.

But let’s be clear: getting your initial costs right is non-negotiable. This is the bedrock of your business. Mess this up, and you could be selling hundreds of shirts while quietly losing money on every single one. It’s the critical difference between building a sustainable brand and running a very expensive, very stressful hobby.

Establishing Your Foundational Shirt Costs

Before you can even dream about profits, you need to know—down to the penny—what it costs to produce a single finished t-shirt. This magic number is your Cost of Goods Sold (COGS). It's your break-even point. Too many newcomers fall into the trap of just looking at the price of the blank tee, and that’s a rookie mistake that can sink a business fast.

The True Cost of Your Blank Garment

The blank shirt is easily your biggest line item, but the price your supplier shows you isn't the final number. You have to think in terms of landed cost—what it actually costs for that box of shirts to arrive at your door. This means factoring in the per-shirt price plus all the shipping fees and taxes.

For instance, say you buy 50 shirts for $4.00 each. That’s $200. But if shipping adds another $25, your real cost per shirt jumps from $4.00 to $4.50. That fifty cents might seem small, but multiply it by a thousand shirts and you see the problem. The type of garment you choose will also heavily influence this cost; our guide on different t-shirt material types is a great resource for understanding how fabric choices affect your bottom line.

Accounting for Consumables and Labor

Now for all the other bits and pieces that go into the final product. These are the variable costs that can fluctuate from one job to the next, so you need a solid handle on them.

- Printing Materials: This is everything from your DTF transfers and screen printing inks to embroidery thread or heat transfer vinyl. You’ll want to calculate this—maybe it's a cost per square inch for a DTF transfer or an estimate of ink usage for a particular design.

- Miscellaneous Supplies: Don't let the small stuff slip through the cracks. Think packing bags, neck labels, finishing sprays, and even the tape on the box. It all adds up.

- Labor: Your time is money. Period. Decide on a fair hourly wage for yourself or your team and track how long it takes to make a shirt. If prepping, printing, and packing takes three minutes and your labor rate is $20/hour, you’ve just added $1.00 in labor to that shirt’s COGS.

Key Takeaway: Every minute of your time and every drop of ink has a price. Ignoring these "small" costs is one of the fastest ways to become unprofitable, even with high sales volume.

To give you a clearer picture, let's break down what this looks like in practice.

Sample Cost Breakdown Per Custom Shirt

Here's a simple table illustrating how to add up all the direct costs to find your COGS for one shirt. This is the number you must cover before you make a single cent of profit.

| Cost Item | Example Cost | Notes |

|---|---|---|

| Blank T-Shirt | $4.50 | This is the landed cost (shirt + shipping/taxes). |

| DTF Transfer | $2.50 | Based on an average-sized chest logo. |

| Labor | $1.00 | Calculated at $20/hour for 3 minutes of work. |

| Packaging | $0.35 | Includes poly mailer bag and any inserts. |

| Total COGS | $8.35 | Your break-even price for this single shirt. |

This $8.35 is your starting point. Any price you set below this means you are actively paying the customer to take your product.

With personalization driving huge market growth, nailing these numbers is more crucial than ever. The global custom t-shirt printing market was valued at a staggering USD 6.46 billion in 2024 and is on a sharp upward trajectory. According to a report from Straits Research on this booming market, the opportunity for smart businesses is massive. By mastering your COGS, you’re not just making shirts—you’re positioning yourself to grab a piece of an industry that’s only getting bigger.

Figuring Out Your Real Production Costs

So, you've got the cost of the blank shirt and the ink figured out. That's a great start, but it's only half the story. If you stop there, you're missing the hidden costs that can eat away at your profits without you even realizing it. These are your overhead costs—all the fixed expenses you have to pay every single month just to keep the doors open.

Think about it. The electricity for your heat press, the rent on your shop (or a portion of your garage), the design software you rely on—none of these are free. Every shirt you print needs to contribute a tiny bit to cover these expenses. Factoring them in is the difference between thinking you’re profitable and actually running a sustainable business.

What's Your Monthly Overhead?

First things first, you need to get a handle on exactly what these costs are. Don't skip this part, even if you're a one-person show working out of your basement. These expenses are real, and they impact your bottom line.

Let's break down what usually falls under overhead:

- Rent or Mortgage: The cost of your physical workspace.

- Utilities: Your electricity, internet, and water bills.

- Software Subscriptions: Monthly fees for tools like Adobe Creative Cloud or CorelDRAW.

- Equipment Payments & Depreciation: The monthly payment on your printer or heat press, plus the reality that it loses value over time.

- Insurance: You absolutely need business liability insurance.

- Marketing & Website Costs: Your Shopify subscription, ad spend, or domain hosting fees.

Add all of those up. A small, home-based business might land around $500 a month in overhead. A dedicated commercial shop? That number could easily jump to $2,500 or more.

I’ve seen people use a general rule of thumb, like adding 15% to their direct costs to cover overhead. It's better than nothing, but taking the time to calculate your actual number gives you a much clearer, more accurate picture of your business's financial health.

Breaking It Down to a Per-Shirt Cost

Once you have your total monthly overhead, you need to spread that cost across all the shirts you produce. To do this, you'll need a realistic estimate of how many shirts you print in an average month. Be brutally honest with yourself here—base it on your actual sales history, not your best-case-scenario dreams.

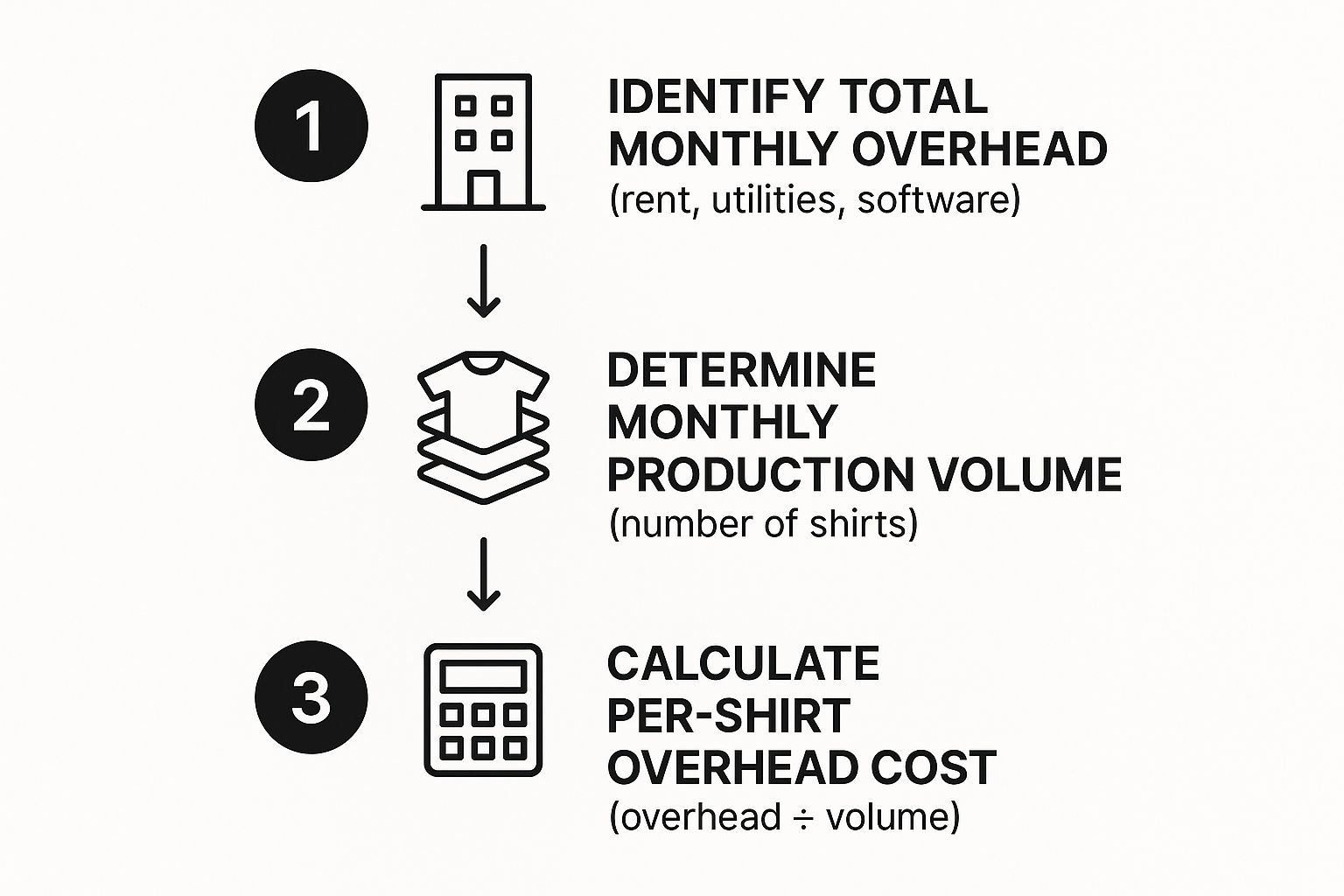

This infographic breaks down a simple way to think about turning that big monthly number into a small, manageable cost for each shirt.

This simple math tells you exactly how much extra you need to build into your pricing just to break even on your fixed expenses.

Let’s run a quick example. Say your shop’s monthly overhead is $1,000, and you typically produce about 500 shirts a month. Your overhead cost per shirt is $2.00 ($1,000 ÷ 500). That $2.00 gets added to your Cost of Goods Sold before you even start thinking about profit.

The good news is that this number isn't set in stone. The more efficient you become, the lower it gets. For some practical ideas on this, check out our guide on how to reduce production costs.

Choosing a Profitable Pricing Strategy

Alright, you've done the hard work of calculating your true costs. That number is your foundation—the bedrock of a profitable business. Now for the fun part: deciding how to price your shirts.

Just picking a number out of thin air or copying what a competitor does is a fast track to frustration. You need a deliberate strategy, one that fits your brand, your customers, and your financial goals.

The Go-To Method: Cost-Plus Pricing

The most straightforward and reliable starting point is cost-plus pricing. It's exactly what it sounds like: you take your total cost per shirt and add a markup for profit. Simple, clean, and it guarantees you make money on every single sale.

For anyone just starting out, this method is your best friend.

So, how much do you add? A solid rule of thumb in the apparel world is to double your costs. Here’s how that breaks down:

- Wholesale Pricing: This is for your bulk orders—think local businesses, school events, or family reunions. The go-to formula is Total Cost x 2.

- Retail Pricing: This is for one-off sales on your website or Etsy shop. A common model here is Wholesale Price x 2, which really just means Total Cost x 4.

Let's use a real-world example. If your all-in cost for one shirt is $10.35, your wholesale price would be $20.70. For a single retail sale, you’d be looking at $41.40. This buffer might seem large, but it's what covers your marketing, potential returns, and most importantly, your own paycheck.

If you want to get deeper into the numbers, our guide on print-on-demand profit margins is a great resource.

Thinking Beyond Costs: The Value-Based Approach

While cost-plus is a safe bet, it doesn't account for the perceived value of your work. That's where value-based pricing comes into play.

Think about it. A complex, multi-location print with intricate artwork is worth far more to a customer than a simple, one-color chest logo. With value-based pricing, you charge based on the uniqueness of the design, the premium quality of the garment, or the story behind your brand.

You aren't just selling cotton and ink; you're selling wearable art. You’re selling a statement piece. That commands a higher price, regardless of what the shirt cost you.

Remember, customers aren't just paying for a shirt; they're paying for your creativity, your expertise, and the solution you provide. Don't be afraid to price your work based on the value it delivers.

A Powerful Tool: Tiered Pricing for Bulk Orders

One of the most effective strategies in this business is tiered pricing. You offer discounts for larger quantities, which gives customers a real incentive to order more. It's a classic win-win: they feel like they’re getting a great deal, and you lock in a bigger, more profitable job.

A simple tiered structure might look something like this:

- 1–11 Shirts: $25.00 each

- 12–24 Shirts: $22.50 each

- 25–49 Shirts: $20.00 each

- 50+ Shirts: $18.00 each

This kind of smart pricing is crucial. The global custom apparel market is valued at over USD 57 billion, and with most shirts retailing between USD 20 to USD 50, strategic models like tiered pricing are what help you grab a piece of that pie. Understanding the latest custom apparel market trends and opportunities will help you position your business for success.

Comparing Popular Pricing Models

Choosing the right pricing model can feel overwhelming, but it really boils down to your specific business goals. Are you focused on volume, perceived brand value, or a simple, foolproof system? This table breaks down the most common strategies to help you decide which path is right for you.

| Pricing Model | How It Works | Best For |

|---|---|---|

| Cost-Plus Pricing | Calculate your total cost per shirt and add a fixed percentage or dollar amount for profit. | New businesses, wholesale orders, and anyone needing a simple, reliable way to ensure profitability on every sale. |

| Value-Based Pricing | Set prices based on the customer's perceived value of the product (e.g., unique design, brand prestige, complexity). | Niche brands, artists, and businesses selling high-end or highly creative custom apparel where cost is secondary to value. |

| Tiered Pricing | Offer incremental discounts per shirt as the order quantity increases. | Businesses targeting bulk orders like teams, companies, or events. Excellent for encouraging larger, more profitable jobs. |

Ultimately, many successful shops use a hybrid approach. You might use cost-plus as your baseline for wholesale, layer in tiered pricing to incentivize bulk orders, and apply value-based thinking for your unique, high-end retail designs. The key is to be intentional and build a strategy that works for you.

Finding Your Place in the Market

Once you’ve got a handle on your costs and a basic pricing model, it’s time to look outside your own shop. Your prices don't exist in a bubble, so the next critical step is to see what your competition is up to. This is all about understanding the landscape so you can position your custom shirts smartly.

This isn’t about copying someone else’s price list. Think of it as gathering intel. You're trying to figure out the "going rate" for different kinds of jobs so you can make a strategic, informed decision. Start by identifying who you’re really up against—this means looking at both the local print shop down the street and the big online behemoths.

See What Others Are Charging

The most straightforward way to begin is to put on your customer hat. Hop onto your competitors' websites and request a few quotes for some classic scenarios.

- Job #1: A simple, one-color logo on the chest of 25 standard cotton t-shirts.

- Job #2: A more involved, three-color design on both the front and back of 50 premium tri-blend tees.

- Job #3: A single, full-color photo shirt, like something you'd sell directly to a customer.

This little exercise arms you with hard data. You'll quickly see how others are pricing for different order sizes, color counts, and printing techniques. But don't just look at the per-shirt price—pay close attention to the other fees. How do they handle setup costs? Shipping? Rush charges? All these things add up to the final price the customer sees.

My Two Cents: Don't just zero in on the final number. Look at how they present their pricing. Is it clear and upfront, or is it a maze of hidden fees? Easy-to-understand pricing builds trust, and that has real value.

Getting a feel for these market averages is crucial because it tells you what customers have been trained to expect. This screenshot from a Wikipedia article on competitive analysis shows a great framework for thinking about this—it’s not just about who your competitors are, but what their strengths and weaknesses are.

This kind of systematic approach helps you move beyond just pricing and into overall business strategy.

Figure Out What Makes You Different

Here's the thing: market research should never be about a race to the bottom. Competing on price alone is a losing game. Instead, use this competitive intel to define your unique selling proposition (USP). What makes your business the better choice?

- Are you the fastest? If you can nail a 24-hour turnaround when everyone else takes a week, that’s a premium service people will pay more for.

- Is your quality top-notch? Maybe you only use the best garments and specialized inks for incredibly soft prints. Your pricing has to reflect that superior quality.

- Do you offer incredible service? Perhaps you give free design assistance or have a super simple, headache-free ordering process. That’s a huge value-add.

It also helps to keep an eye on global trends. The Asia-Pacific region dominates the market, making up over 39.4% of revenue, largely because lower manufacturing costs allow for rock-bottom prices, sometimes as low as $8–$15 for a basic shirt. You can dig into global market dynamics on Grand View Research to learn more.

Knowing this doesn't mean you have to compete with those prices. It means you can position your business as the premium, domestic, or high-quality alternative. You're not just selling a shirt; you're selling speed, quality, or service—and you can price accordingly to attract customers who value what you do best.

Adjusting Prices for Different Order Types

In the custom apparel world, a static, one-size-fits-all price list is a surefire way to leave money on the table. The shops that thrive are the ones that learn to price their work dynamically. Your pricing structure needs to be as flexible and adaptable as your printing skills.

This is all about moving past a simple per-shirt cost. You need to build a system that accounts for the complexity, urgency, and premium touches that make each job unique. It's how you make sure you’re paid fairly for your hard work while giving clients a price they can understand.

Factoring in Design and Print Complexity

Let's be real: not all prints are created equal. A simple, one-color logo on the chest is a walk in the park compared to a six-color beast with a back print and a sleeve hit. The second job takes way more time, materials, and setup, and your pricing has to reflect that.

Think about building in surcharges for the common variables you'll encounter.

- Multiple Print Locations: A flat fee for each extra spot is the way to go. For example, you might add $3.00 for a back print and another $1.50 for a sleeve logo.

- Number of Colors: This is a big one for screen printers. Every color is another screen, more setup time, and more ink. A per-color fee is standard practice—something like $0.50 per extra color, per shirt.

- Design Complexity: That super-intricate design with fine lines or a vintage distressed look? It's going to take more finessing in prep and might slow you down on the press. Don't be shy about adding a small "complexity fee" for art that requires extra attention.

With this approach, your price scales directly with your workload. A customer with a basic job pays your base price, while someone with a more demanding request compensates you for the extra effort.

The Rush Order Premium

It’s going to happen. A client will call you in a panic needing an order yesterday. It feels great to be the hero who saves the day, but those last-minute jobs throw a wrench in your whole production schedule. They often mean staying late and pushing other clients' work back.

You absolutely have to charge a premium for that convenience.

A rush fee isn't about punishing the client; it's about compensating your shop for the disruption. A tiered structure is usually the fairest way to handle it.

| Turnaround Time | Surcharge Example |

|---|---|

| Standard (5-7 Days) | 0% (Base Price) |

| Expedited (3 Days) | +25% of Total Order |

| Next-Day Service | +50% of Total Order |

Pro Tip: Be crystal clear about what constitutes a "business day" and set a firm cut-off time for accepting rush orders. This kind of transparency avoids so many headaches and manages client expectations right from the get-go.

Increasing Value with Smart Upsells

Upselling is one of the easiest ways to boost your average order value without having to rethink your entire pricing model. It's not about being pushy; it's about offering clients valuable add-ons that make their final product even better (and make you more profitable).

Instead of just quoting the most basic option, guide them toward premium choices that might actually be a better fit.

- Premium Garments: I’m a big fan of the "Good, Better, Best" model. Show them the standard Gildan or Hanes, but also have a softer, more stylish option like a tri-blend or a premium brand like Next Level on hand. Most people will happily pay a few extra dollars for a shirt they'll actually love to wear.

- Finishing Services: Simple touches can add a ton of perceived value for a relatively low cost to you. Think about offering custom-printed neck tags, individual folding and bagging, or even branded hang tags. These are the details that make an order feel truly professional.

When you master these adjustments, you stop just selling shirts and start providing a truly tailored service. This strategic thinking is how you ensure every single order is priced fairly and, most importantly, profitably.

Common Questions About Pricing Your Shirts

Figuring out how to price your custom shirts can feel like a moving target. Just when you think you've got a system, a unique request throws a wrench in your plans. Let's tackle some of the most common questions that pop up for both new and established apparel businesses.

How Much Profit Should I Actually Make Per Shirt?

There’s no single right answer here, but a healthy profit margin in the custom apparel world usually lands somewhere between 30% and 50%.

Let's say your total cost to produce a shirt is $10. A 30% margin would mean you sell it for $14.30, while a 50% margin prices it at $20.00.

Your market makes a huge difference, though. If you're selling directly to customers online or at an event, shooting for that 50% margin (which is a 100% markup) is a solid target. But for big wholesale orders, your margin on each individual shirt will naturally be lower. That's okay, because the overall profit on the job makes it well worth your while.

Should I List My Prices on My Website?

This is the age-old debate in the custom apparel community. On one hand, putting your prices out there is transparent. It saves you time by automatically filtering out people who can't afford your work, and it makes the buying process straightforward for customers who are ready to go.

On the other hand, hiding your prices forces potential clients to reach out. This is your golden opportunity to start a conversation, learn about their project, and really sell them on the value you bring. For complex jobs with a lot of variables, you almost have to do this to create an accurate quote.

A hybrid approach is often the sweet spot. You could list "starting at" prices for simple, popular jobs (like "Starting at $15 for a one-color front print on 24+ shirts"). For anything more custom, require a quote. This gives people a general idea while still encouraging them to talk to you.

How Do I Handle Those Tiny, One-Off Order Requests?

We all get them. "Can you just make one shirt?" These can be real profit-killers because your setup time is the same whether you're printing one shirt or fifty.

You've got two solid ways to handle this:

- Set a Minimum Order Quantity (MOQ): This is the cleanest route. An MOQ of 12 or 24 pieces is standard in the industry. It ensures every job you fire up the press for is actually worth your time.

- Charge a "Small Order Fee": If you really want to take on those tiny jobs, you have to charge a hefty premium. This isn't about gouging them; it's about fairly covering your fixed costs. Be transparent about this fee so the customer understands why a single shirt costs what it does.

What's the Best Way to Price for Non-Profits?

Working with charities and non-profits requires a bit of finesse. You want to help them out, but you can't give your work away for free and stay in business.

A great strategy is to offer them your absolute best price tier—the same per-shirt rate you'd give a massive corporate client ordering thousands of pieces, even if they're only ordering a few dozen. This gives them a real, tangible discount without you losing money. You could also offer to sponsor their event by adding your small logo to the sleeve in exchange for an even better price.

At Cobra DTF, we provide the high-quality, USA-made DTF transfers that are the foundation of a profitable custom shirt business. With our competitive pricing and fast, reliable shipping, you can keep your costs low and your quality high.

Explore our premium DTF transfers and start printing smarter today!