Cotton vs Polyester Sweatshirt A Complete Guide

Share

When it comes to picking a sweatshirt for your DTF printing business, the core difference between cotton and polyester is simple. Cotton gives you that soft, breathable feel everyone loves for casual wear. On the other hand, polyester brings durability and eye-popping print vibrancy to the table, making it a champ for athletic gear.

Your decision really boils down to what you want to offer your customers: a cozy, natural-feeling garment or a long-lasting sweatshirt with brilliant, sharp colors.

Choosing The Right Sweatshirt For DTF Printing

Getting into the custom apparel game means your choice of fabric is everything. It's the canvas for your art. For DTF (Direct-to-Film) printing, the cotton vs. polyester debate is more than just about how the fabric feels—it directly affects how your prints look, how long they last, and ultimately, how people see your brand.

Nailing down the differences between these two fabrics is your first step to making sweatshirts that don't just look amazing off the press but also hold up to what your customers expect. If you're just getting started with this method, it's worth taking a moment to understand what Direct-to-Film printing is and how it works.

Key Fabric Attributes At A Glance

Cotton is a natural fiber, and its claim to fame is its incredible softness and breathability. It’s the kind of material people want for everyday, comfortable clothing because it absorbs moisture well. The downside? It can shrink, and colors can fade after a bunch of washes.

Polyester is the complete opposite. It’s a synthetic powerhouse known for wicking moisture, standing up to abuse, and resisting both shrinking and wrinkles. That’s why you see it everywhere in sportswear. However, it doesn't have that natural, airy feel of cotton and can sometimes feel a bit slick against the skin.

So, how does this play out with DTF printing? The adhesive powder on your transfers sticks great to both, but the end result is noticeably different. A design printed on cotton tends to have a softer, more integrated look, almost like it’s part of the fabric itself. On polyester, that same print will sit more on the surface, making the colors appear sharper and more vibrant.

Key Takeaway: There's no single "best" fabric—it all depends on the situation. Match your sweatshirt to its purpose. Go with cotton for lifestyle brands where comfort is king, and choose polyester for athletic apparel where performance is the goal.

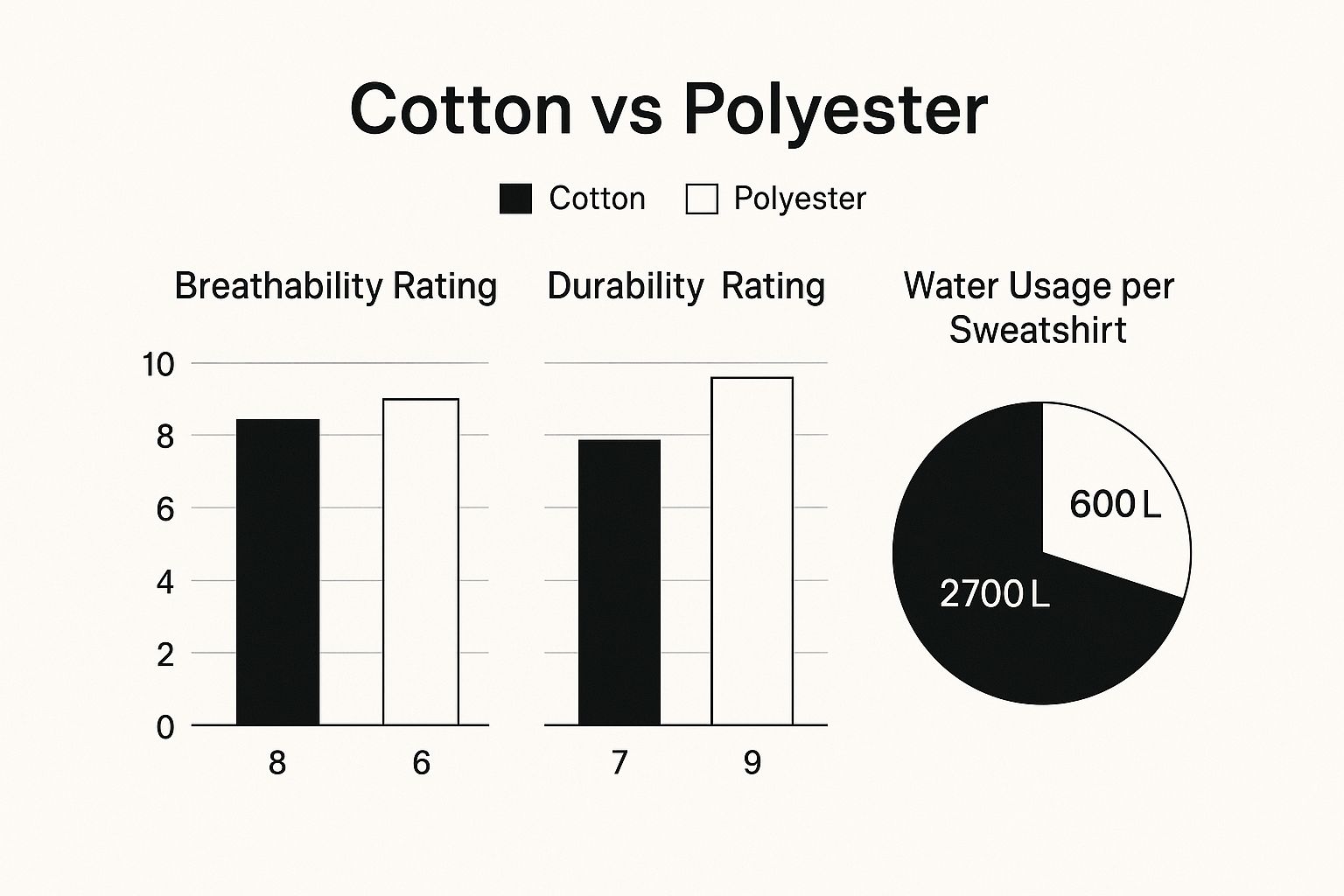

This image really helps visualize the trade-offs you're making between the two fabrics when it comes to breathability, durability, and even their environmental footprint.

As you can see, cotton wins on breathability, but polyester has a clear edge in durability and requires significantly less water to produce.

Quick Comparison Cotton vs Polyester for DTF

To make things a bit easier, I've put together a table that breaks down how each fabric stacks up in the areas that matter most for a DTF printing business. Think of it as your cheat sheet for making the right call.

| Attribute | Cotton Sweatshirt | Polyester Sweatshirt |

|---|---|---|

| Print Vibrancy | Softer, more matte finish | Brighter, more vivid colors |

| Feel & Comfort | Very soft, breathable, natural feel | Smooth, synthetic feel, less breathable |

| Durability | Good, but prone to fading/shrinking | Excellent, resists shrinking and fading |

| Moisture Control | Absorbs moisture, slow to dry | Wicks moisture away, dries quickly |

| Ideal Use Case | Casual wear, lifestyle brands | Athletic apparel, workwear |

| DTF Adhesion | Excellent, bonds well with fibers | Excellent, smooth surface for transfers |

| Upfront Cost | Generally slightly higher | Typically more affordable |

This table should give you a clear, at-a-glance understanding of where each material shines. Use it to quickly align your fabric choice with the product you're aiming to create.

Understanding the Fibers: Cotton vs. Polyester

Before we can even talk about printing, we have to get back to basics. The cotton vs polyester sweatshirt conversation really starts at the fiber level. Each material has its own DNA, a unique set of traits that dictates how a sweatshirt feels, wears, and—most importantly for us—how it takes a DTF print.

Cotton is the classic choice, a natural fiber that's been the bedrock of the textile world for ages. It’s all about comfort. Think soft, breathable, and gentle on the skin. It’s the fabric people know and love.

Polyester is the modern workhorse. It’s a synthetic, engineered from the ground up for performance and durability. It was created to do things cotton simply can't. Knowing the science behind each one is what separates a good printing decision from a great one.

The Natural Comfort of Cotton

When you pick up a 100% cotton sweatshirt, the first thing you notice is the feel. Its biggest selling point is that unmatched comfort and breathability. The organic structure of cotton fibers lets air flow right through, so it doesn't trap heat. That's why it's the go-to for relaxed, everyday apparel.

Cotton is also a thirsty fiber; it's highly absorbent. This is great for comfort, as it can pull moisture away from the skin, but it's a bit of a double-edged sword. Once it's wet, it gets heavy and takes a long time to dry.

Cotton’s real magic is its premium, organic feel. It delivers a sense of quality that customers instantly connect with, making it the perfect canvas for lifestyle brands or high-end casual wear where the customer experience is everything.

If you want to go deeper into how these fabrics stack up for different types of clothing, check out our guide on the fundamental differences between cotton and polyester.

The Engineered Performance of Polyester

Polyester was built to solve cotton’s weaknesses. Its number one advantage? Durability. The synthetic fibers are incredibly tough—they resist stretching, shrinking, and the general wear and tear of daily life. A polyester sweatshirt will keep its shape and color far longer than a cotton one.

The other game-changer is that polyester is hydrophobic, which is a fancy way of saying it hates water. Instead of soaking up sweat like cotton, it wicks moisture to the surface where it evaporates in a flash. This is precisely why you see polyester everywhere in the athletic world.

Key Performance Traits of Polyester:

- Exceptional Durability: Stands up to abuse, making it perfect for rugged workwear or team uniforms that get washed constantly.

- Moisture-Wicking: Pulls sweat off the skin, keeping the wearer dry and comfortable during a workout or on a hot day.

- Wrinkle Resistance: Stays smooth right out of the dryer, a huge plus for travel apparel or anyone who hates ironing.

- Color Retention: Dyes lock into the synthetic fibers, meaning less fading and more vibrant colors that last.

These built-in features make polyester the obvious choice when performance is the name of the game. Its smooth, less porous surface also creates a perfect base for DTF transfers, often producing sharper, more brilliant prints that really pop. Ultimately, the decision isn't about which fabric is "better," but which is the right tool for the specific job you're trying to do.

Analyzing DTF Print Quality and Color Vibrancy

This is where the rubber meets the road. In the cotton vs polyester sweatshirt debate, the real test for any DTF business is the print itself. How a transfer looks, feels, and ultimately holds up depends entirely on the tiny, microscopic interaction between the ink, the adhesive, and the fabric fibers.

It’s here that the core differences between natural cotton and synthetic polyester create two totally different results. Getting this right isn't just about aesthetics; it’s a technical choice that dictates the visual pop and durability of everything you sell.

How DTF Adhesive Bonds to Each Fabric

The magic behind a solid DTF print is the hot-melt adhesive powder. When you press it, this powder liquifies and essentially glues the ink to the sweatshirt. But the way it bonds is completely different for cotton and polyester.

Cotton fibers are naturally porous and absorbent—think of them as tiny sponges. When you press a DTF transfer onto a cotton sweatshirt, the melted adhesive actually seeps into those fibers, creating a deep, mechanical lock. The result is a print that feels much softer, like it’s part of the garment.

Polyester is a different beast. As a synthetic plastic, its fibers are smooth and non-porous. The adhesive can't sink in, so it forms an incredibly strong bond right on the surface. This creates a highly durable layer, but one that you can feel sitting on top of the fabric more than you would on cotton.

Key Insight: Cotton gives you a softer, more integrated print because the adhesive bonds with the fibers. Polyester delivers a sharper, more durable surface bond because the adhesive sticks to the fibers.

This single difference in bonding mechanics influences everything from the print's texture to how well it resists peeling down the line.

Color Vibrancy and Print Finish

Ever wonder why colors seem to explode off a polyester garment? It goes back to how the ink interacts with the surface. Since the DTF transfer sits cleanly on top of polyester’s non-absorbent fibers, the ink layer reflects way more light. The payoff is a vibrant, almost glossy finish. This makes polyester the undisputed champ for designs that need to scream, like sports team logos or bold, graphic artwork.

Cotton, on the other hand, with its absorbent nature, causes the ink and adhesive to settle into the fabric just a little bit. This gives you a softer, more matte finish. The colors are still fantastic and accurate, but they have a slightly more subdued, almost vintage feel that many fashion and lifestyle brands are chasing.

Think about the end product:

- Polyester: The go-to for high-impact graphics. Colors are incredibly sharp, crisp, and vivid.

- Cotton: Perfect for artistic designs or brands wanting that premium, retail-soft hand feel. The print looks and feels more organic.

Don't underestimate the market's love for cotton's classic comfort. In 2023, cotton sweatshirts dominated the market, valued at a massive $10.08 billion. And that demand isn't slowing down. You can dig into the numbers yourself in this in-depth hoodies and sweatshirts market analysis.

The Challenge of Dye Migration on Polyester

For all its color-popping glory, polyester has one major technical headache: dye migration. This happens when the dye used to color the polyester fabric gets hot during pressing and turns into a gas (a process called sublimation). That gas then seeps right through your DTF transfer, staining the white ink and ruining your design.

Picture this: you press a beautiful white logo onto a red polyester sweatshirt, and it comes out looking pink and faded. It’s a classic, costly mistake for anyone new to printing on synthetics.

To stop this, you absolutely must use DTF transfers that include a dye-blocking layer. This is a special charcoal or black adhesive layer on the back of the transfer that acts as a barrier, stopping the fabric dyes from bleeding through. For printing on dark or bright polyester, this isn't optional—it's essential for a professional job. It adds a little to your cost, but it saves you from a world of frustration and wasted inventory.

How Well Do They Hold Up? A Look at Durability and Longevity

A killer DTF print is just the start. The real test is how that sweatshirt looks after it's been worn, washed, and loved. When we talk cotton vs polyester sweatshirts, we’re really talking about how a garment is going to live its life. How it performs after a dozen washes is what builds your reputation and keeps customers coming back.

The longevity of your printed apparel comes down to two very different materials. Cotton, with its classic, natural feel, tends to age gracefully but shows its wear. On the other hand, polyester, the synthetic workhorse, is built tough but has its own quirks over time.

The Life of a Cotton Sweatshirt

A 100% cotton sweatshirt has a personality that changes over time. Being a natural fiber, it reacts to every wash and dry cycle. The biggest thing to watch for is shrinkage, especially if it hits hot water or a high-heat dryer. A good quality cotton blank might only shrink 3-5%, but cheaper ones can shrink significantly, which can warp the print right along with the fabric.

A DTF print on cotton almost becomes one with the garment. As the cotton fibers naturally soften and the color mellows out, the print can take on a softer, more vintage vibe. This isn't a defect—in fact, for a lot of lifestyle and fashion brands, this natural aging is exactly the look they're going for.

The Takeaway: The print on a cotton sweatshirt tells a story, aging right alongside the fabric. The main concern isn't the print cracking or peeling; it's the garment itself changing shape or fading around it.

Polyester’s Endurance and Its Achilles' Heel

Polyester sweatshirts are engineered to last. These synthetic fibers are incredibly tough, giving them a serious advantage against shrinking, stretching, and fading. A DTF print on a poly garment stays looking crisp and bright through a ton of washes because the fabric it’s on doesn’t change.

But polyester isn’t perfect. Its main enemy is pilling—those annoying little fuzzballs that show up on the surface from friction. You’ll usually see it under the arms or where a seatbelt or backpack strap rubs. While the print itself holds up perfectly, pilling around it can make the whole sweatshirt look tired and worn.

The DTF transfer also sits more on top of the polyester fibers. The bond is super strong, but if it’s not cared for properly (think scorching hot water or harsh chemicals), the print might feel a bit stiff or, in rare cases, develop tiny cracks after years of abuse. Still, pilling is by far the more common issue.

The Wash Test: A Head-to-Head Comparison

The laundry room is where the truth comes out. To give you a real sense of what to expect, here’s a look at how each fabric holds up after about 50 wash cycles.

| Durability Factor | Cotton Sweatshirt | Polyester Sweatshirt |

|---|---|---|

| Shape Retention | Can shrink a bit or stretch out over time, which might change the overall fit. | Holds its shape incredibly well. Resists shrinking and stretching, looking new for longer. |

| Color Fastness | The fabric's color will likely fade gradually, creating that soft, broken-in aesthetic. | The color stays deep and vibrant with very little fading, even after many washes. |

| Print Integrity | The DTF print stays put but will soften and settle into the fabric as it ages. | The print remains sharp, crisp, and bright, looking almost exactly like it did on day one. |

| Fabric Pilling | Much less likely to pill. The surface generally stays smooth. | Prone to pilling in high-wear spots, which can detract from the sweatshirt's look. |

In the end, deciding between cotton and polyester on durability is about managing expectations. Cotton gives you a product that "wears in," developing character. Polyester gives you one that "wears out" much more slowly, resisting change. Knowing this difference is key to helping your customers choose the right blank, whether they need a tough-as-nails work uniform or a stylish piece for their clothing line.

A Practical Cost and ROI Analysis for Your Business

When it comes down to it, profitability is the name of the game. Your decision in the cotton vs polyester sweatshirt debate will hit your bottom line directly. While it's tempting to grab the cheaper polyester blanks, the real cost is a lot more than the price per unit. A smart business owner looks at the whole picture—hidden costs, potential waste, and market value—to see the true return on investment (ROI).

This isn't just about the invoice from your supplier. It's about understanding the total cost of a finished, sellable product. Getting this right is crucial for setting prices that guarantee a healthy profit margin.

Uncovering the Hidden Costs

The sticker price on a blank sweatshirt is just where your math starts. Some fabrics bring along extra operational costs that can quietly shrink your profits if you're not paying attention.

Take polyester. It often demands special dye-blocking DTF transfers to stop that dreaded dye migration, especially on darker colors. Those transfers cost more than standard ones, which adds up with every single sweatshirt you press. There's also the constant risk of scorching the fabric if your heat press is even a little too hot, leading to wasted inventory and lost money.

Cotton isn't entirely without its own quirks, though. Cheaper, low-quality cotton is notorious for shrinking, which can lead to a wave of customer complaints and returns—another hidden cost. This is why investing in better-quality cotton blanks often pays for itself by protecting your brand's reputation and avoiding those post-sale headaches.

Key Financial Insight: Your true cost-per-garment isn't just the price of the blank. It's the blank, plus the right transfer, plus a buffer for potential mistakes. That lower upfront cost for polyester can disappear fast once you factor in the necessary production adjustments.

Tying Fabric Choice to Market Value and ROI

What you can actually sell a sweatshirt for depends heavily on the fabric and who you're selling it to. This is where you connect your costs to your revenue.

A high-performance polyester sweatshirt, aimed at an athletic team or the outdoor gear market, can easily command a premium. Customers in that niche are looking for durability and moisture-wicking features, and they're willing to pay for it. Your ROI here comes from marketing the sweatshirt as specialized technical apparel.

On the other hand, a heavyweight, premium cotton sweatshirt can fetch a high price in the streetwear or lifestyle market. Here, the soft feel, breathability, and classic look are what people value. The market sees cotton as a quality, comfortable fiber, and that perception drives up its value. In fact, cotton hoodies accounted for about 45.4% of the global market share in 2024, proving their massive consumer appeal. You can dig into these trends by exploring insights on the global hoodies market.

To get a handle on how these factors impact your real-world earnings, check out our guide on how to calculate print-on-demand profit margins.

Business ROI Breakdown: Cotton vs. Polyester Sweatshirts

To make this crystal clear, let's break down the financials. This table illustrates how the initial costs, potential issues, and market perception of each fabric translate into tangible business outcomes.

| Financial Factor | Cotton Sweatshirt | Polyester Sweatshirt | Business Implication |

|---|---|---|---|

| Blank Cost | Moderate to High | Low to Moderate | Polyester often has a lower upfront cost, which is attractive for bulk orders. |

| Printing Costs | Standard DTF transfers | Requires pricier dye-blocking transfers | The cost to print on polyester is higher, narrowing the initial price gap. |

| Waste Potential | Low (Shrinkage on low-quality blanks) | Moderate (Risk of scorching, dye migration) | Mistakes with polyester are more costly due to specialized materials. |

| Market Value | High (Lifestyle, Streetwear) | High (Athletic, Performance wear) | Both can sell at a premium, but only when targeted to the right audience. |

| Potential ROI | High | High | Profitability depends entirely on aligning fabric choice with market demand and pricing. |

Ultimately, your best ROI comes from a smart strategy. You need to match your fabric choice to a specific customer's needs and price your products to reflect their perceived value. By understanding both the full production cost and what the market will bear, you can pick the fabric that delivers the biggest win for your business.

Matching the Fabric to Your Customer

So, which sweatshirt is better? The truth is, it's not about cotton versus polyester—it's about who you're selling to. The "best" sweatshirt is simply the one that fits your customer's needs, and making that connection is what separates a good print shop from a great one.

When you stop thinking about fabric specs and start thinking about your customer's world, you'll make smarter, more profitable choices every time.

For High-End Streetwear and Lifestyle Brands

If you're printing for a brand where the feel is as critical as the design, you can't go wrong with heavyweight cotton. Think premium lifestyle brands, boutique streetwear lines, or any customer focused on pure quality and comfort.

From the moment they pick it up, they'll notice the difference. Cotton’s substantial weight, natural softness, and breathability create a truly premium experience. This audience craves that authentic, classic feel, and cotton delivers. Plus, a DTF print on cotton has a unique way of settling into the fibers, giving it a soft, almost integrated look that perfectly matches a high-end aesthetic.

Our Take: For any brand built on a reputation for quality and comfort, 100% heavyweight cotton is non-negotiable. Yes, the blank costs more, but the perceived value allows you to command a much higher price point, making it a sound investment.

For Athletic Teams and Performance Gear

When you're outfitting athletes, function is everything. Whether it's for a local sports team, a gym, or an outdoor work crew, they need gear that can keep up. This is where 100% polyester shines.

Its moisture-wicking ability is the star of the show, pulling sweat away from the body to keep the wearer dry and comfortable during a workout or a long day on the job. Polyester is also tough as nails, standing up to repeated, harsh washings without shrinking or losing its color. And for team branding, nothing makes a logo pop quite like a DTF print on polyester—the colors come out incredibly sharp and vibrant.

For Corporate Clients and Promotional Events

This is probably the biggest market out there. Corporate clients, event organizers, and businesses ordering promotional wear are trying to hit a sweet spot: they need something that looks professional, feels good, and won't break the bank. For them, a cotton-polyester blend is the perfect solution.

A 50/50 or 60/40 blend really does give you the best of both worlds:

- Comfort: The cotton brings that familiar softness and breathability.

- Performance: The polyester adds durability, wrinkle resistance, and shape retention.

- Printability: Blends are a fantastic canvas for DTF, giving you vibrant prints without the dye migration headaches of 100% polyester.

- Price: They're almost always more affordable than 100% cotton, which is a huge deal when you're quoting bulk orders.

This versatility makes blended sweatshirts the reliable workhorse for a massive chunk of the custom apparel industry. Knowing these use cases inside and out will help you guide your clients to the perfect garment every single time.

Got Questions About Sweatshirt Fabrics? We've Got Answers.

Even with all the details laid out, you might still be wrestling with a few specific questions about cotton versus polyester. That's completely normal. Let's tackle some of the most common questions we hear from print shop owners to help you lock in your decisions with confidence.

Are Cotton-Polyester Blends a Smart Move for DTF Printing?

Absolutely. In fact, for many in the DTF game, cotton-poly blends are the go-to sweet spot. They give you the best of both worlds: the soft, premium feel of cotton that customers love, plus the strength and color-holding power of polyester. It’s a workhorse fabric that just works.

When it comes to the DTF transfer itself, the adhesive grabs onto blended fibers beautifully. This gives you a print that not only looks sharp but feels great and holds up wash after wash. Blends also won't shrink on you like 100% cotton can, and you get to dodge the tricky dye migration issues that plague 100% polyester. It's a reliable, low-headache choice for most projects.

Do I Really Need to Change My DTF Settings for Cotton vs. Polyester?

Yes, and this is non-negotiable. Dialing in the right heat press settings for each fabric is the difference between a professional product and a pile of wasted inventory. It's one of the most critical steps in the whole process.

Think of it this way:

- Cotton: It’s a tough, natural fiber. It can take the heat, so you'll typically press it somewhere between 300-320°F.

- Polyester: This is a synthetic, which is just a fancy word for a type of plastic. Too much heat will melt or scorch the fibers. You need to drop your temperature way down, usually to the 260-280°F range.

Here's a pro tip: For dark polyester, always use a transfer with a dye-blocking layer built-in. This is your shield against the fabric’s dye bleeding into your white ink during pressing. And no matter what, always press a sample first.

Which Fabric Is Actually Better for the Environment?

This is a tough one, and the "better" choice really comes down to what your brand values most when it comes to sustainability. Each has its own baggage.

Conventional cotton farming is notoriously thirsty, requiring immense amounts of water and pesticides. But organic cotton flips the script, offering a much greener alternative by cutting out the harsh chemicals. Plus, as a natural fiber, cotton is biodegradable.

Polyester, on the other hand, is made from petroleum. It's plastic. Every time you wash it, it sheds microplastics. The silver lining here is the boom in recycled polyester (rPET), which turns old plastic bottles into new fabric. This is a huge win, as it keeps plastic out of landfills and reduces our reliance on new oil.

So, if your brand leans toward a natural, earthy vibe, organic cotton is probably your best bet. If you’re making performance gear and want to highlight recycling, rPET is a fantastic story to tell.

Ready to produce incredible, long-lasting prints no matter which fabric you choose? Cobra DTF offers premium, American-made DTF transfers that deliver vibrant colors and amazing durability. Get consistent results every time with our fast, reliable shipping. Explore our products and see the difference.