Top Inventory Management Best Practices for Apparel Success

Share

For small apparel and printing businesses, inventory is both your biggest asset and your greatest liability. A shelf stacked high with blank t-shirts, rolls of vinyl, and thread spools represents potential profit, but it also ties up cash and occupies valuable space. Mismanage it, and you face stockouts that disappoint customers, or dead stock that eats into your margins. Effective inventory management isn't just about counting what you have; it's a strategic discipline that directly impacts your profitability, operational efficiency, and customer satisfaction.

Getting this right means you can confidently accept that large custom print order, knowing you have the materials. It means avoiding last-minute, expensive rush orders for a popular shirt color. This guide moves beyond generic advice to provide a comprehensive list of actionable inventory management best practices tailored specifically for the unique challenges of the apparel and print industry. We will dive into specific, practical techniques that you can implement immediately to gain control over your stock, reduce waste, and unlock capital.

You'll learn how to prioritize your most valuable items, calculate the perfect order size, and implement systems for real-time tracking. We'll cover everything from ABC analysis for your blank apparel to optimizing safety stock levels for specialty inks. While our focus is on apparel and print, the core principles of stock optimization are universal. For a broader perspective on optimizing your stock, exploring these 9 Inventory Management Best Practices for Retailers can offer valuable insights beyond the apparel and print sector. Let's transform your inventory from a source of stress into a streamlined, profit-generating engine for your business.

1. ABC Analysis Classification

One of the most effective inventory management best practices is to stop treating all your stock equally. ABC analysis, rooted in the Pareto principle, is a method of categorizing inventory items based on their significance to your overall business value. This technique helps you prioritize your time, resources, and capital on the items that matter most.

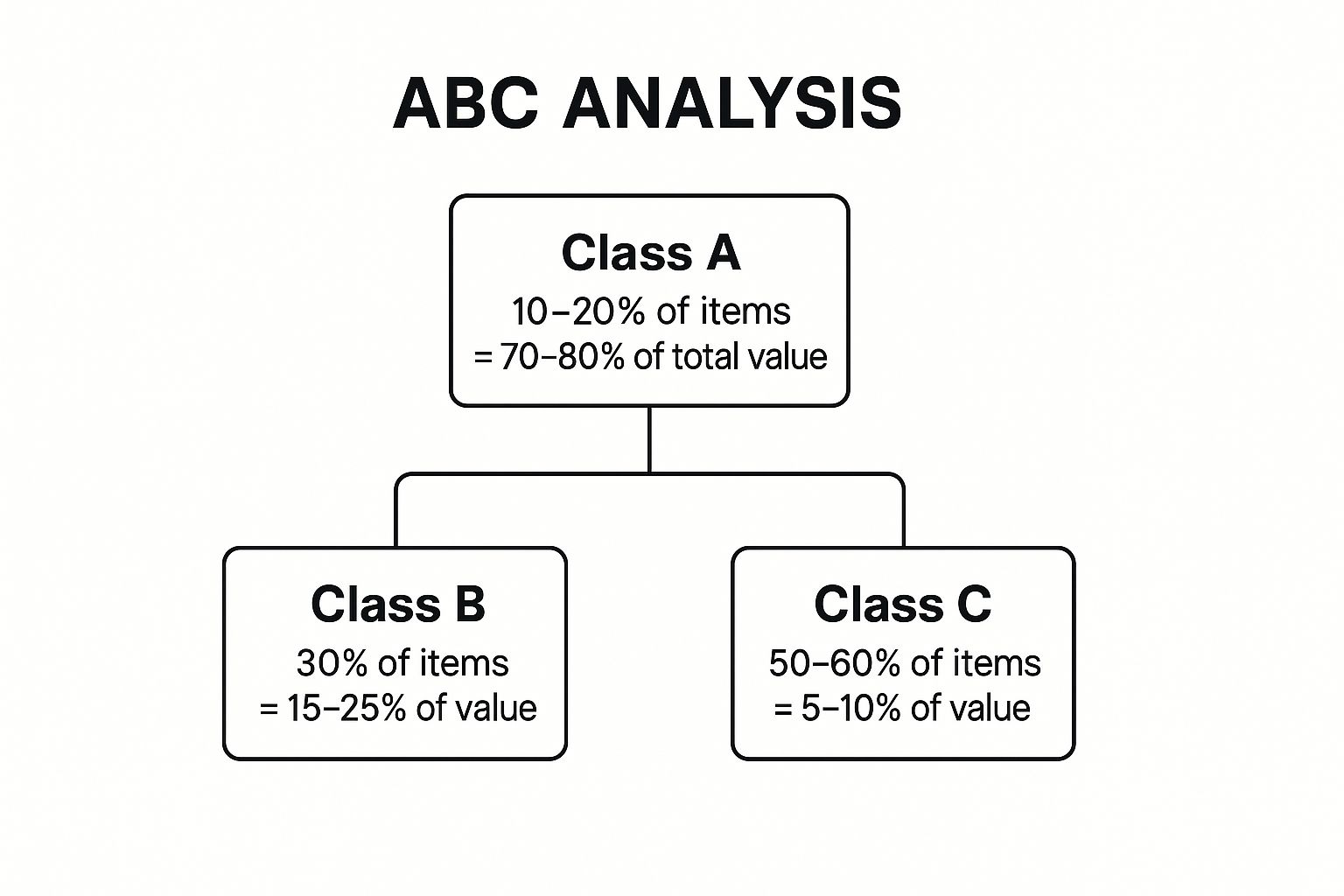

The system divides your inventory into three distinct classes:

- Class A: These are your most valuable products. While they typically make up only 10-20% of your total inventory items, they account for a massive 70-80% of your annual consumption value. For an apparel business, this could be your best-selling premium hoodies or a highly popular custom t-shirt design. These items require strict inventory control, frequent reviews, and secure storage.

- Class B: This category represents items of moderate value. Comprising about 30% of your inventory items, they contribute 15-25% of the total value. These might be standard-quality blank tees or less popular color options for a best-selling item. They require less stringent control than Class A items but more than Class C.

- Class C: These are your low-value, high-quantity items. Making up over 50% of your stock items, they often represent only 5-10% of the total value. Think of items like basic ink supplies, packing tape, or last season’s clearance apparel. These items can be managed with simpler, less frequent controls.

The following infographic illustrates the hierarchical relationship between these inventory classes, showing how a small percentage of items drives the majority of value.

This hierarchy clearly demonstrates the disproportionate value distribution across your inventory, underscoring why focused management on Class A items is crucial for profitability.

How to Implement ABC Analysis

To get started, calculate the annual consumption value for each inventory item by multiplying its annual demand by its unit cost. Rank all items from highest to lowest value and then create percentage-based cutoffs for each class. Use this classification to tailor your reordering policies, cycle counting frequency, and even warehouse layout, placing Class A items in easily accessible locations. For optimal results, review and update your classifications quarterly to adapt to changing sales trends and seasonality.

2. Just-In-Time (JIT) Inventory

Another of the most impactful inventory management best practices is the Just-In-Time (JIT) methodology. Popularized by Toyota, this lean strategy involves receiving goods from suppliers only as they are needed for the production process. The core goal is to minimize waste and reduce the significant costs associated with holding excess inventory, such as storage fees, insurance, and the risk of obsolescence.

For an apparel printing business, implementing JIT means that blank t-shirts, hoodies, or specialty inks arrive just before they are scheduled for a specific customer's print run. This approach prevents capital from being tied up in stock that isn't actively generating revenue. It requires a highly coordinated supply chain and precise demand forecasting to ensure production is never halted by a lack of materials.

The benefits of a well-executed JIT system are substantial:

- Reduced Holding Costs: By minimizing the stock you keep on-hand, you dramatically lower expenses related to warehouse space, staffing, and potential damage or spoilage of inventory.

- Improved Cash Flow: Money is not locked into unsold goods, freeing up capital that can be invested in other areas of your business, like marketing or new printing technology.

- Less Waste: The risk of inventory becoming outdated is nearly eliminated. For apparel businesses, this is crucial for avoiding being stuck with last season's styles or colors.

- Increased Efficiency: JIT forces a more streamlined and responsive production process, helping to identify and eliminate bottlenecks in your workflow from order to delivery.

How to Implement JIT Inventory

A successful JIT system hinges on precision and strong supplier partnerships. Start by identifying your most reliable suppliers who can guarantee quick and consistent delivery times. Use inventory management software with robust forecasting tools to predict demand accurately based on historical sales data and market trends.

Begin with a small-scale pilot program, perhaps applying JIT principles to one or two of your most predictable, high-volume products, like a standard white blank t-shirt from a local vendor. As you refine the process and strengthen supplier communication, you can gradually expand the strategy across more of your product lines. This methodical approach helps mitigate risks while allowing you to reap the powerful cost-saving benefits of lean inventory management.

3. Economic Order Quantity (EOQ)

One of the most crucial inventory management best practices involves moving beyond guesswork and using data to determine how much stock to order. The Economic Order Quantity (EOQ) model is a time-tested formula that calculates the ideal order size to minimize the combined costs of ordering inventory and holding it. It strikes the perfect balance between the costs that decrease with larger orders (like shipping and processing fees) and the costs that increase (like storage and insurance).

The EOQ formula considers three key variables to find the most cost-effective order quantity:

- Demand: The annual demand for a specific product in units. For a printing shop, this would be the total number of a popular blank t-shirt model you sell per year.

- Order Cost: The fixed cost incurred each time you place an order. This includes administrative expenses, shipping fees, and the cost of processing the order, regardless of the quantity.

- Holding Cost: The cost to hold one unit of inventory for a year. This encompasses storage space costs, insurance, potential spoilage, and the opportunity cost of capital tied up in stock.

By balancing these factors, the EOQ model helps prevent both costly overstocking and disruptive stockouts. It provides a precise, data-driven answer to the fundamental question: "How much should I order at one time?" This approach is a cornerstone of efficient inventory management, ensuring capital isn't wasted on excess stock or frequent, small orders.

How to Implement the EOQ Model

To apply the EOQ formula, first gather accurate data on your annual demand, fixed ordering costs, and per-unit holding costs. The basic formula is: EOQ = √[(2 x Annual Demand x Order Cost) / Holding Cost]. For instance, if you sell 1,200 black hoodies annually, your order cost is $50, and your holding cost is $5 per hoodie, your EOQ would be approximately 155 units per order.

For best results, regularly review and update your cost assumptions, as shipping rates and storage fees can change. Also, consider integrating this model with a reorder point formula, which tells you when to order, creating a comprehensive and automated system for your most stable products.

4. Real-Time Inventory Tracking

Moving beyond manual spreadsheets is one of the most transformative inventory management best practices for a growing apparel or printing business. Real-time inventory tracking involves using technology to monitor stock levels, locations, and movements instantly across all your channels. This eliminates the guesswork and delays associated with manual counts, providing an accurate, live view of your entire operation.

This approach leverages tools like barcode scanners, RFID tags, and cloud-based inventory management systems to automate data capture. Every time a blank t-shirt is received from a supplier, a custom hoodie is printed, or a finished product is shipped, the system updates immediately. This instant visibility prevents stockouts on popular items, minimizes overstocking of slow-moving designs, and provides the data needed for accurate demand forecasting.

For a printing business, this means knowing exactly how many medium-sized black hoodies you have on hand before accepting a large rush order. Similarly, an e-commerce apparel store can sync its online storefront with its physical warehouse, automatically updating stock levels as sales occur to prevent overselling.

How to Implement Real-Time Tracking

Getting started requires a strategic approach to technology adoption. Begin by integrating a barcode system for all your products, from blank apparel to finished goods. A simple USB scanner and inventory management software can be a cost-effective first step.

- Choose Scalable Technology: Select an inventory management system that can grow with your business. Look for solutions that integrate with your existing e-commerce platforms (like Shopify or WooCommerce) and accounting software.

- Implement in Phases: Don't try to overhaul everything at once. Start with your highest-value (Class A) items or a single product category to pilot the system. This allows you to work out kinks and train staff effectively before a full-scale rollout.

- Prioritize Staff Training: Your system is only as good as the people using it. Ensure your team understands the importance of scanning every item at every stage, from receiving to fulfillment, to maintain data accuracy.

5. Safety Stock Optimization

An essential element of any robust inventory management strategy is building a buffer against uncertainty. Safety stock optimization is the practice of holding just enough extra inventory to prevent stockouts caused by unpredictable demand spikes or supply chain delays. It is a calculated safeguard that ensures you can continue fulfilling orders even when things do not go as planned, protecting customer satisfaction and revenue.

This buffer stock is not just guesswork; it is a strategic reserve calculated to balance risk with cost. For an apparel business, this could mean holding extra units of a best-selling black t-shirt that faces fluctuating demand or has a supplier with an inconsistent delivery record. The goal is to avoid both lost sales from stockouts and the high carrying costs of excessive inventory.

- Supply Uncertainty: Your supplier for a specific heat transfer vinyl might experience production delays, or a shipment of blank hoodies could get stuck in transit. Safety stock covers your production needs until the new shipment arrives.

- Demand Uncertainty: A social media trend could cause a sudden surge in demand for a particular custom tote bag design. Safety stock allows you to capitalize on this unexpected popularity without making customers wait.

The key is optimization. Holding too much safety stock ties up cash and warehouse space, while holding too little risks disappointing customers and losing sales. Effective inventory management best practices involve finding the precise, data-driven balance between these two extremes.

How to Implement Safety Stock Optimization

Calculating safety stock requires moving beyond simple assumptions. A common formula involves multiplying your maximum daily usage by your maximum lead time and then subtracting the product of your average daily usage and average lead time. However, you can start with a simpler approach and refine it.

Begin by analyzing historical sales data to identify demand variability and track supplier lead times to understand their reliability. Classify your products using ABC analysis and apply more sophisticated safety stock calculations to your Class A items, which have the biggest impact on your bottom line. Regularly review and adjust these levels, especially for seasonal items like holiday-themed apparel, to ensure your buffer reflects current market conditions and supply chain performance.

6. Regular Cycle Counting

Relying on a single, massive annual physical inventory count is a reactive and often disruptive practice. A more effective and proactive approach is regular cycle counting, a perpetual auditing method where a small subset of your inventory is counted on a continuous, rotating schedule. This technique transforms inventory auditing from a dreaded annual event into a manageable, ongoing process that significantly improves accuracy.

Instead of shutting down operations for a full-scale count, you can count different items daily, weekly, or monthly. This provides a constant stream of accurate data, allowing you to identify and correct discrepancies like shrinkage, damage, or receiving errors in near real-time. For an apparel business, this means you can quickly spot if a box of medium-sized hoodies was mislabeled as large before it causes major fulfillment issues.

This method can be tailored to fit your inventory's value and velocity:

- High-Value Items: Your best-selling custom print shirts or premium blank hoodies might be counted weekly to ensure their stock levels are always precise. This minimizes the risk of overselling popular products.

- Moderate-Value Items: Items like specialty vinyl or standard-quality apparel might be counted monthly. This maintains a good level of accuracy without dedicating excessive resources.

- Low-Value Items: Consumables such as ink cartridges or packing supplies can be counted quarterly, as discrepancies here have a lower financial impact.

Adopting regular cycle counting is one of the most powerful inventory management best practices for maintaining a healthy and accurate stock ledger, which is the foundation for efficient ordering, production planning, and customer satisfaction.

How to Implement Cycle Counting

Start by integrating cycle counting with your ABC analysis. Use the classification to set the counting frequency for different items: Class A items are counted most frequently, followed by B, and then C. Schedule counts during low-activity periods, such as the beginning or end of shifts, to minimize disruption to your printing or fulfillment operations.

Equip your team with mobile scanners or tablets to record counts directly into your inventory management system, which reduces data entry errors. Crucially, establish a clear process for investigating and resolving any discrepancies immediately. Finding out why a count is off is just as important as the count itself. This continuous verification helps you maintain unparalleled inventory accuracy throughout the year.

7. Demand Forecasting and Planning

Moving beyond reactive ordering is a hallmark of mature inventory management best practices. Demand forecasting and planning involves using historical data and market analysis to predict future customer demand. This forward-looking approach allows apparel and printing businesses to make informed decisions, ensuring the right amount of stock is on hand to meet orders without tying up capital in excess inventory.

Accurate forecasting enables you to optimize stock levels, minimize carrying costs, and avoid stockouts on popular items. It transforms your inventory from a static cost center into a dynamic asset that responds to market needs. For an apparel business, this could mean predicting the demand for seasonal items like fleece jackets before winter hits or anticipating a surge in a specific t-shirt color based on emerging fashion trends.

Key components of effective demand forecasting include:

- Quantitative Forecasting: This method relies on historical sales data to predict future trends. Techniques like moving averages or exponential smoothing are used to identify patterns in past performance, which is ideal for stable, consistently selling products like classic white tees.

- Qualitative Forecasting: When historical data is scarce, such as when launching a new product line, this method uses market research, expert opinions, and customer surveys to gauge potential demand. It’s highly useful for anticipating the success of a unique, custom-printed hoodie design.

- Causal Forecasting: This advanced approach analyzes the relationship between demand and external factors like marketing promotions, economic trends, or even competitor actions to create a more nuanced prediction.

How to Implement Demand Forecasting

Start by gathering and cleaning at least one to two years of historical sales data for your products. Analyze this data to identify trends, seasonality, and any cyclical patterns. Next, choose a forecasting model that fits your business; a simple moving average is a great starting point for beginners.

Continuously monitor the accuracy of your forecasts by comparing them against actual sales. Collaborate closely with your sales and marketing teams to incorporate their insights on upcoming promotions or market shifts. As your business grows, consider investing in inventory management software with built-in forecasting tools to automate and refine the process, ensuring your predictions become more accurate over time.

8. Supplier Relationship Management

Effective inventory control extends beyond your warehouse walls and into your relationships with the businesses that supply your raw materials. Supplier Relationship Management (SRM) is a strategic approach that treats your vendors as partners rather than just transactional entities. This practice focuses on building long-term, collaborative relationships to improve reliability, reduce costs, and create mutual value, which is one of the most crucial inventory management best practices for a stable supply chain.

For an apparel or printing business, a strong relationship with your primary blank t-shirt or ink supplier can mean the difference between meeting a tight deadline and losing a major client. SRM involves more than just negotiating prices; it encompasses joint planning, performance monitoring, and open communication to ensure your supply chain is resilient and efficient.

This approach transforms the supplier dynamic from a simple cost-based interaction into a strategic partnership. The benefits include:

- Improved Reliability: Strong relationships often lead to prioritized order fulfillment, better lead time consistency, and a more reliable supply of critical materials like specific fabric blends or specialty inks.

- Reduced Risk: A collaborative partnership allows for greater transparency into your supplier's operations, helping you anticipate potential disruptions and work together on contingency plans.

- Cost Savings: Beyond lower unit prices, SRM can reduce costs associated with stockouts, quality defects, and rush shipping fees. Partners are more likely to offer favorable terms or volume discounts.

- Innovation: Suppliers are experts in their field. A close partnership can provide early access to new materials, technologies, or printing techniques, giving you a competitive edge.

How to Implement Supplier Relationship Management

Start by segmenting your suppliers, much like you would with an ABC analysis for inventory. Identify your most critical partners, those who supply high-value or hard-to-replace items, and focus your SRM efforts there. Establish clear Key Performance Indicators (KPIs) to track supplier performance, such as on-time delivery rates, quality acceptance rates, and price competitiveness.

Schedule regular meetings to review performance, discuss upcoming forecasts, and address any challenges. Maintain open and honest communication, providing constructive feedback and being transparent about your own business needs. Investing in these partnerships builds trust and a more robust supply chain, ensuring you have the materials you need, when you need them.

9. Inventory Turnover Optimization

One of the most critical inventory management best practices is mastering how quickly you sell and replace your stock. Inventory turnover optimization focuses on maximizing this cycle, measured by the inventory turnover ratio. This metric reveals your efficiency in converting inventory into sales, directly impacting cash flow, profitability, and storage costs.

A high turnover rate is a sign of a healthy business. It means your products are in demand, your capital isn't tied up in slow-moving items, and you reduce the risk of stock becoming obsolete, which is a major concern with fast-changing apparel trends. It indicates strong sales and effective marketing. Conversely, a low turnover rate can signal overstocking, poor sales, or a disconnect with customer demand.

- Fast Fashion Example: Retailers like Zara are masters of high turnover, introducing new, limited-run styles frequently to create urgency and clear out stock before trends fade.

- Apparel Business Example: For a custom printing shop, a high turnover on popular blank t-shirt sizes (like Large and XL) shows you are stocking correctly, while a low turnover on 3XL sizes might suggest you are over-ordering them.

- Electronics Example: Companies like Best Buy must optimize turnover to avoid holding onto technology that quickly becomes outdated, similar to how apparel businesses must avoid last season’s styles.

This focus on turnover ensures that your capital is constantly working for you, rather than sitting idle on a warehouse shelf. It's a key indicator of your overall operational efficiency and market responsiveness.

How to Optimize Inventory Turnover

Start by calculating your inventory turnover ratio (Cost of Goods Sold / Average Inventory). This gives you a baseline. From there, set specific and realistic turnover targets for different product categories. For example, your goal for core best-selling blank tees should be much higher than for niche, seasonal items like holiday-themed hoodies.

To improve your ratio, implement strategic markdowns or promotional bundles for items that have been sitting for too long. Regularly analyze sales data to identify these slow movers before they become a significant problem. Balancing a high turnover rate with maintaining adequate stock to prevent stockouts is crucial. You want to sell through inventory quickly but not so quickly that you disappoint customers who can't find what they want. Review and adjust your targets and strategies quarterly to adapt to market changes.

10. Multi-Location Inventory Balancing

As your apparel or printing business expands to multiple storefronts, warehouses, or fulfillment centers, simply managing each location’s stock in isolation becomes inefficient. Multi-location inventory balancing is a sophisticated strategy for optimizing stock distribution across your entire network. This approach involves strategically transferring inventory between locations to meet demand where it’s highest, reducing both stockouts and costly overstock situations.

This system moves beyond individual location management to a holistic, network-wide view. Instead of each store reordering a slow-moving t-shirt design from a supplier, one location can simply transfer its excess stock to another where that design is selling well. This coordination, often powered by a centralized system, is one of the most impactful inventory management best practices for growing businesses.

For apparel brands, this practice is critical. Consider these scenarios:

- Regional Demand Shifts: A sudden cold snap in one city boosts demand for hoodies, while another city remains warm. Inventory balancing allows you to shift hoodie stock from the warm location to the cold one, capturing sales that would otherwise be lost.

- Online vs. In-Store: Your online store sells out of a popular custom print design, but a physical retail location has plenty of stock. A multi-location system enables ship-from-store capabilities, fulfilling the online order from the retail store’s inventory and delighting the customer.

- Event-Based Needs: A pop-up shop or a local event requires a specific set of merchandise. Instead of placing a new wholesale order, you can pull the required stock from other, slower-moving locations in your network.

This approach transforms your separated inventory pools into a single, flexible asset, allowing you to respond dynamically to market changes and improve overall capital efficiency.

How to Implement Multi-Location Inventory Balancing

Start by implementing a centralized inventory management system that provides real-time visibility across all locations. Establish clear and efficient transfer policies, outlining the process, costs, and lead times for moving stock between sites. Use sales data and forecasting analytics to proactively identify rebalancing opportunities rather than reacting to stockouts. Factor in transportation costs to ensure that each transfer is profitable, and centralize your safety stock planning to hold less buffer inventory overall while still protecting against demand uncertainty across the entire network.

Inventory Management Best Practices Comparison

| Inventory Strategy | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| ABC Analysis Classification | Low to moderate 🔄 | Low to moderate ⚡ | Focused control on high-value items 📊 | Inventory prioritization and resource allocation | Simplifies control; optimizes resource use ⭐ |

| Just-In-Time (JIT) Inventory | High 🔄 | High ⚡ | Reduced inventory costs; waste minimization 📊 | Lean manufacturing and demand-driven supply chains | Minimizes carrying costs; improves efficiency ⭐ |

| Economic Order Quantity (EOQ) | Moderate 🔄 | Moderate ⚡ | Optimal order sizes; cost minimization 📊 | Stable demand environments needing cost-efficiency | Clear ordering guidelines; minimizes costs ⭐ |

| Real-Time Inventory Tracking | High 🔄 | High ⚡ | Instant stock visibility; fewer errors 📊 | Complex, multi-location inventory management | Automated updates; enhances accuracy ⭐ |

| Safety Stock Optimization | Moderate 🔄 | Moderate ⚡ | Reduced stockouts; better service levels 📊 | Demand and supply uncertainty management | Balances availability with cost control ⭐ |

| Regular Cycle Counting | Moderate 🔄 | Moderate ⚡ | Continuous accuracy; early error detection 📊 | Ongoing inventory validation without shutdowns | Maintains accuracy; improves reporting ⭐ |

| Demand Forecasting and Planning | High 🔄 | High ⚡ | Improved inventory planning; reduced stockouts 📊 | Planning for variable demand and seasonal trends | Enhances resource allocation; lowers costs ⭐ |

| Supplier Relationship Management | High 🔄 | High ⚡ | Reliable supply; risk mitigation 📊 | Strategic supplier partnerships and collaboration | Improves quality; reduces risks and costs ⭐ |

| Inventory Turnover Optimization | Moderate 🔄 | Moderate ⚡ | Faster sell-through; improved cash flow 📊 | Retail and fast-moving consumer goods | Boosts efficiency; reduces obsolescence ⭐ |

| Multi-Location Inventory Balancing | High 🔄 | High ⚡ | Optimized stock distribution; service level 📊 | Multi-warehouse/store networks | Reduces total inventory; maximizes availability ⭐ |

Turning Your Inventory into a Competitive Advantage

The journey through the core principles of inventory management reveals a powerful truth: your stock is not just a collection of assets, but the very engine of your apparel or printing business. Moving beyond simply storing T-shirts, ink, or vinyl, you can transform your inventory into a strategic advantage that fuels growth, boosts profitability, and enhances customer satisfaction. The difference between a thriving shop and one that struggles often lies in the mastery of these details.

We've covered a wide range of strategies, from the Pareto Principle-driven logic of ABC Analysis to the lean efficiency of Just-In-Time (JIT) ordering. Each of these inventory management best practices serves a unique purpose, but their true power is unleashed when they work in concert. Implementing them is not about adopting a rigid, one-size-fits-all system; it's about building a flexible, intelligent framework tailored to the specific rhythms of your business.

From Theory to Tangible Results

The shift from reactive to proactive inventory control is where the real value emerges. Instead of scrambling to fill backorders or liquidating dead stock at a loss, you can begin to anticipate market needs with confidence.

- Financial Health: By calculating your Economic Order Quantity (EOQ) and optimizing your inventory turnover ratio, you directly impact your cash flow. Capital that was once tied up in excess stock can be reinvested into new equipment, marketing campaigns, or expanding your product line.

- Operational Efficiency: Techniques like real-time tracking and regular cycle counting eliminate guesswork and costly manual errors. This precision means your team spends less time searching for items and more time on value-added activities like production and customer service.

- Customer Loyalty: Nothing erodes trust faster than a stockout on a popular item. By implementing safety stock protocols and accurate demand forecasting, you ensure product availability, meet customer expectations, and build a reputation for reliability.

Your Actionable Path Forward

Mastering these concepts requires a commitment to continuous improvement. The goal is not to achieve a static "perfect" state but to create a dynamic system that adapts to your evolving business. Here are your immediate next steps:

- Start Small, Win Big: Don't try to implement all ten strategies at once. Choose one or two that address your most pressing pain points. If you're constantly running out of your best-selling blank shirts, start with ABC Analysis to classify your stock and then apply safety stock calculations to those "A" items.

- Leverage Technology: Manually tracking every item is unsustainable. Invest in a simple inventory management system that can automate tracking and provide the data needed for forecasting and analysis. Even a well-organized spreadsheet is a step in the right direction.

- Strengthen Partnerships: Your suppliers are crucial allies. Open a dialogue with them about your goals for JIT or improving lead times. Strong supplier relationships can lead to better terms, more reliable delivery, and valuable market insights.

Ultimately, adopting these inventory management best practices is about gaining control. It's about making informed, data-driven decisions that replace assumptions and anxiety with strategy and confidence. As you refine your approach, you'll find that your inventory stops being a source of stress and becomes a powerful lever for sustainable growth. To put these strategies into a broader context and ensure holistic success, review these Essential Inventory Management Best Practices to see how they fit within a complete operational framework.

Ready to streamline your printing process and reduce wasted inventory? The direct-to-film solutions from Cobra DTF allow for on-demand, high-quality prints, minimizing the need to hold large stocks of pre-printed apparel. Explore how our technology can support your lean inventory goals at Cobra DTF today.